FOB Price

Get Latest Price( Negotiable )

|1 Set Minimum Order

Country:

Algeria

Model No:

JH-GBPL

FOB Price:

( Negotiable ) Get Latest Price

Place of Origin:

-

Price for Minimum Order:

-

Minimum Order Quantity:

1 Set

Packaging Detail:

Standard package for exportation suitable for long distance transport

Delivery Time:

30-120days, according to the order quantity

Supplying Ability:

50 Set per Year

Payment Type:

L/C, T/T

Product Group :

Algeria

Contact Person Mr. Brahim

Economical Zone, Ghardaia, Other

About Yurui

Shandong Yurui is a manufacturer and trading company involved with high-tech building materials equipments, and is at the industry leading level in the field of building materials. The products manufactured by our company mainly include: building materials equipment, mining equipment, etc. All of our products have passed ISO9001:2000 International Quality Management System certification.

Take automatic wall plaster machine for example:

Brief introduction of automatic wall plaster machine

As production line of gypsum board is more and more popular, its production technology is also gradually developing to the direction of large scale production.

Shandong Yurui has many years experience in the manufacturing of gypsum board, gypsum powder, and gypsum block equipment; has been appointed by the national ministry of commerce as fixed-point equipment manufacturer.

According to our tens years production experience, and the survey of the users, we believe automatic wall plaster machine is the most preferred choice, and have been providing users with advanced high-quality gypsum processing plan.

Advantage &features of automatic wall plaster machine

1. Automatic wall plaster machineis easy to form a complete set. In addition to the production unit dedicated part, the rest equipments are of domestic standard to form a complete set of equipment, in strict accordance with ISO9001. Key electronic components adopt international famous company high quality products, guarantee to provide customers high quality, reliable operation of equipment.

2. The scale of production and factory building are moderate with the current production line automation and mechanization degree; are easy to manage.

3. Automatic wall plaster machine adopts advanced technology from Germany. The company research and development staff carefully started key parts such as dosing, forming and drying process to design a high efficiency, stability and energy saving equipment.

4. Automatic wall plaster machineoperates slower than 25 m/min. The circular operating speeds up to 30 ~ 40 m/min, is adapting to the supply of raw materials at present. There is no special requirement for raw materials.

5. Less investment, mature production process. Production cycle is short and with fast effect. Easy to guarantee the quality .

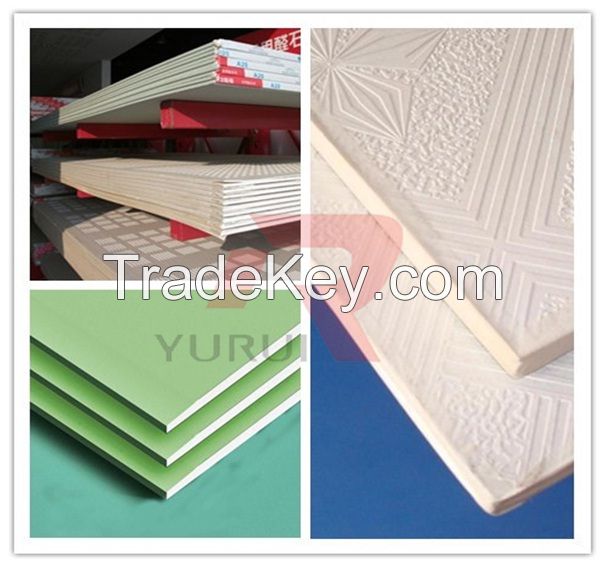

Products Specification of Automatic wall plaster machine

|

Legth (mm) |

2400,2440,2500,2700,3000 |

|

Width (mm) |

1200,1220 |

|

Length/width deviation (mm) |

Length 0-6 ; width 0-5 |

|

Thickness (mm) |

8,9,9.5,12,12.5,12.7,15,18 |

|

Thickness deviation (mm) |

0±0.5 0±0.6 |

|

Catercorner deviation |

≤5 |

|

Breaking load of board (N) |

9.5: lengthways>=360horizontal>=140 |

|

12: lengthways≥500horizontal≥180 |

|

|

Moisture content |

< 2% |

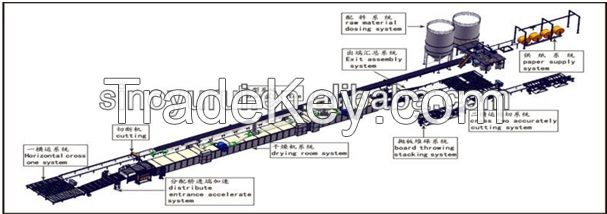

Production process of Automatic wall plaster machine

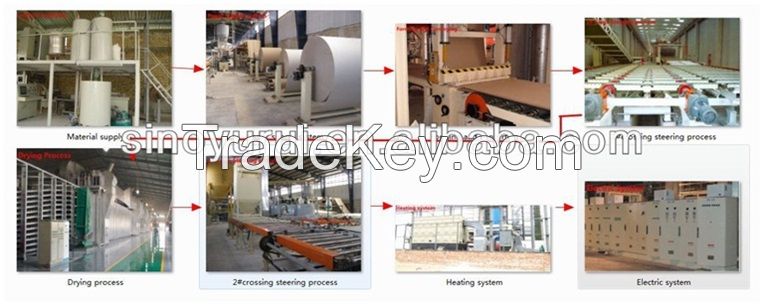

1.Dosing Process of Automatic wall plaster machine

Material Preparation: After quantitative measurement, put modified starch, retarder, paper pulp, water reducing agent and water in the hydrapulper to form a pulp of raw material, then pump them into the slurry storage tank as standby; proportionally put the foaming agent and water in foaming agent preparation tank and stir uniformly, then pump them into the foaming agent reserve tank (with heating device to keep the temperature at or above 35°C) as standby; coagulant and gypsum powder raw materials enter into the silo as standby through elevating and conveying equipment. Dosing: Use metering pump to pump the slurry into the mixer, use dynamic foaming device to foam the foaming agent and into a mixer, use automatic belt weigher to measure the coagulant and gypsum powder and into the mixer, then blend all the main and auxiliary materials in a mixer into qualified gypsum slurry.

2. Forming and Conveying Process of Automatic wall plaster machine

The upper paper enters forming machine through automatic rectify deviation machine after uncoiling, the lower paper enters forming machine through automatic rectify deviation machine, scoring machine and vibration platform after uncoiling, the slurry of the mixer falls onto the lower paper of vibration platform and enters forming machine, the forming machine squeezes out plasterboard of requested specifications, and then finish the initial solidification on solidification belt and the final solidification on rollgang, use fixed-length cutting machine to cut the plaster board to a required length (2400mm,3000mm or others), the two plaster boards, after the redirection by cross steering machine 1#, leave the machine1# at the same time, use roller bed to make the spacing of the two boards to meet the requirements, and finally enter drying machine through distributor for drying.

3. Drying Process of Automatic wall plaster machine

Using fuel type heat conduction oil furnace as the heat source, the hot oil, after goes through fin heat exchanger, becomes hot wind and enters drying machine to complete the drying task. The drying machine is divided into 2 areas, which can nicely finish the drying curve of gypsum board in drying process, avoiding defects such as over burning, wetting and so on. This process is environmental protective, energy saving, high thermal efficiency, and the process parameters are easy to control.

4. 2# Cross Steering process of Automatic wall plaster machine

After the drying machine finishes drying task, the boards are conveyed to 2 # cross steering system via plate discharging machine to complete fixed-length cutting of the gypsum board and automatic edge sealing, then send them into automatic stacker for stacking through finished product conveyor. Use forklift to send the products to packing areas for inspection and packaging. The whole set of production process is complete.

Our service of Automatic wall plaster machine

Pre-sale Services: Yurui provides you with the prophase plan, process flow design and manufacture equipment according to your special demand.

SaleServices: Yurui sends technicians to the jobsite for guiding the installation and adjustment,commissioning , training operators and finishing the check and accept together with you, ,as well as turnkey project for customers. Your team can start your project in a best status

After-sale Services: We can supply after-sale service overseas. Whenever need our overseas service, we will be here.

Some pictures of Automatic wall plaster machine

Yurui scenery

| Country: | Algeria |

| Model No: | JH-GBPL |

| FOB Price: | ( Negotiable ) Get Latest Price |

| Place of Origin: | - |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | 1 Set |

| Packaging Detail: | Standard package for exportation suitable for long distance transport |

| Delivery Time: | 30-120days, according to the order quantity |

| Supplying Ability: | 50 Set per Year |

| Payment Type: | L/C, T/T |

| Product Group : | Gypsum machinery |