FOB Price

Get Latest Price( Negotiable )

|10 Ton Minimum Order

Country:

China

Model No:

34CrNiMo6(1.6582) Steel

FOB Price:

( Negotiable ) Get Latest Price

Place of Origin:

-

Price for Minimum Order:

-

Minimum Order Quantity:

10 Ton

Packaging Detail:

W-Nr 34CrNiMo6 Forged Alloy Steel: Seaworthy Package or Customized.

Delivery Time:

30 Days, DIN 1.6582

Supplying Ability:

1000 Ton per Month

Payment Type:

T/T, L/C, D/A, D/P

Product Group :

-

Contact Person Mr. Hunter

fuhongsteel@gmai.com, Wuxi, Jiangsu

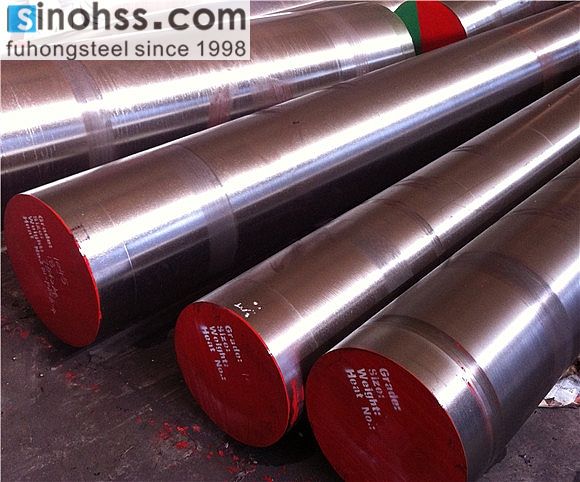

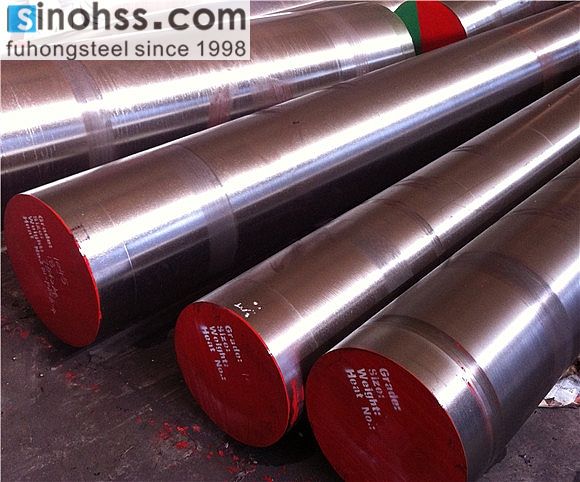

34CrNiMo6/1.6582 Alloy

Steel Round bars

DIN 34CrNiMo6/1.6582 alloy steel

manufacturers and suppliers, as forged supplied in round

bars,square/flat bars,rollers,shafts,blocks,as rolled mainly

provided in round rods.

DIN 34CrNiMo6/1.6582 alloy steel

manufacturers and suppliers, as forged supplied in round

bars,square/flat bars,rollers,shafts,blocks,as rolled mainly

provided in round rods.

34CrNiMo6 steel is a common

nickel-molybdenum alloy steel accding to DIN standard,and 1.6582

steel is under W-Nr Germany standard.It is a high strength steel

and has good comprehensive mechanical properties.DIN 1.6582 steel

is widely used in the manufacture of the camshaft and connecting

rod of engine parts, poor processability, belongs to the typical

difficult-to-machine materials.

1.Chemical

Composition

Carbon:0.30/0.38; Silicon:Max0.40;

Manganese:0.50/0.80;

Chromium:1.30/1.70;

Molybdenum:0.15/0.30; Nickel:1.30/1.70;

2.Form &

Size

-DIN 34CrNiMo6 Alloy Steel

as Forged

1)Fuhongsteel manufactures and

supplies 34CrNiMo6 forged steel round bars,square bar,flat

bar,shaft,and blocks.

2)DIN 34CrNiMo6 alloy steel size

available:

Round

bar

Size: Dia.80-1,000mm

Length: 3,000-10,000mm

Square

bar

Size: 150×150-500×500mm

Length: 3,000-8,000mm

(Forged flat bars,Blocks,Shafts and

forging pieces can be customized)

-W-Nr 1.6582 Alloy Steel as

Rolled

1)Fuhongsteel is a quality steel

supplier of 1.6582 rolled steel round bars.

2)W-Nr 1.6582 alloy steel round bar

size available:

Size: Dia.10-300mm

Length: 3,000-10,000mm(can be

customized)

3.Tolerances on Dimension

& Straightness

1)Black surface:-0/+8mm;

2)Machined

surface:-0/+3mm;

3)Deviation from straightness:with

360° rotary device 2mm/meter(max)

4.Quality

Certificate

1)Chemical composition:Related DIN

7527-6 , EN 10250-3

2)Mechanical properties -Tensile

strength -Yield point -Percentage reduction of area after fracture

-Elongation after fracture -Impact test: Impact test must be done

on three (3) different ISO-V samples at +20 C°

3)Non metallic inclusions

4)Grain size:According to DIN 50601

more than 5,preferred to 8;

5)Ultra sonic testing 360° complete

round testing: Ultra sonic according to EN 10228-3

5.Applications

34CrNiMo6 steel is often used in the

manufacture of shaft under high load, such as connecting rod

structure.DIN 1.6582 steel is also made the surface is hard

wear-resisting and heart of flexible components, such as gear.It is

also widely used in engine camshaft and connecting rod

parts.

6.Forging

1)Preheat 1.6582 forged alloy steel

carefully.

2)Raise the forging temperature up

to 1150-1200°C.

3)Keep the forging temperature above

850°C.

7.Heat

Treatment

Hardening&Tempering(quenched and tempered

and after stress relieved)

1)Heating 34CrNiMo6 steel uniformly

to 850°C;

2)W-Nr 1.6582 alloy steel should be

quenched in the oil;

3)Heat the material to the

temperature 550°C;

4)Soak at this temperature for at

least 2 hours;

5)1.6582 alloy steel should be

cooled in the furnace.

In case after QT a straightening

process is necessary then the products should be tempered and

distorsion-poor annealed with at least more than 625°C.

Annealing

1)Heating 1.6582 forged steel

thoroughly to 800-850°C;

2)Cool slowly to the temperature

550°;

3)Complete annealing the steel in

the air.

Normalizing

1)heat DIN 1.6582 steel until the

temperature up to 850°C;

2)Then cool W-Nr 34CrNiMo6 steel

down to the room temperature in the air.

| Country: | China |

| Model No: | 34CrNiMo6(1.6582) Steel |

| FOB Price: | ( Negotiable ) Get Latest Price |

| Place of Origin: | - |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | 10 Ton |

| Packaging Detail: | W-Nr 34CrNiMo6 Forged Alloy Steel: Seaworthy Package or Customized. |

| Delivery Time: | 30 Days, DIN 1.6582 |

| Supplying Ability: | 1000 Ton per Month |

| Payment Type: | T/T, L/C, D/A, D/P |

| Product Group : | - |