FOB Price

Get Latest Price750 ~ 2500 USD / Ton

|10 Metric Ton Minimum Order

Country:

China

Model No:

API 5L

FOB Price:

750 ~ 2500 USD / Ton Get Latest Price

Place of Origin:

-

Price for Minimum Order:

750 per Ton

Minimum Order Quantity:

10 Metric Ton

Packaging Detail:

Bulk cargo, pipe cap, steel strips bundled

Delivery Time:

30-45days after receiving the deposit

Supplying Ability:

1000 Ton per Month

Payment Type:

Western Union, D/A, L/C, T/T

Product Group :

Contact Person SUN

Tianjin, Tianjin

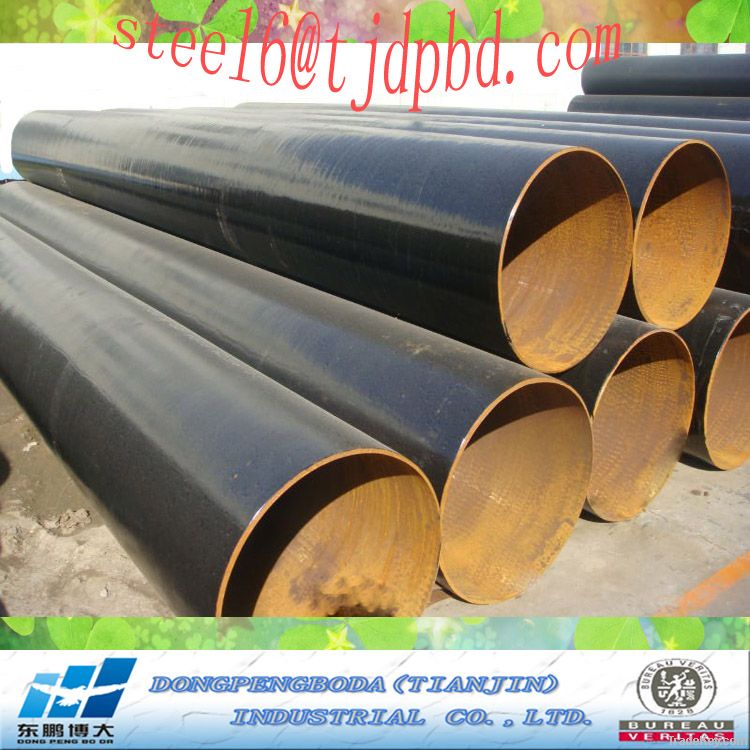

API 5L large diameter sprial welded steel pipe

1. Product

|

Spiral Welded Pipe/Sprial Tube/Spiral Steel

Tube

|

|

| Thickness | 3.***0mm |

| OD | *******0mm |

| Length | **********0mm |

| Standard | SY/T********0,GB/T***1.*****7,GB/T***1.2,API*5L,SY/T******2 |

| Material | Q**5A,Q**5B,Q**5,L**5,L**0,X*2,X*2,X*0,X*0,X*0,0Cr*3,1Cr*7, |

| *0Cr*9Ni*1,1Cr*8Ni9,0Cr*8Ni*1Nb | |

| Tolerance | Wall thickness :+/*3% |

| Out diameter :+/**5mm | |

| Application | Mainly used in water engineering, petrochemical industry , chemical |

| industry, power industry, agricultural irrigation, urban construction. | |

| For liquid transportation:water supply, water drainage, sewage treatment | |

| engineering, transmission mud, sea water | |

| For gas transmission:coal gas,vapour, liquefied petroleum gas | |

| For construction :as piling tube ,as bridge;dock, road, building structure | |

| pipe, marine piling tube | |

| Inspection | hydraulic testing, eddy current and infrared test |

| Payment | TT ,**0% irrevocable L/C at sight |

| Packing | wrapped by steel strips in bundles or as required |

| Market | North America, South America, Europe, Middle East, Southeast Asia, Australia and Central Asia and many other countries and regionsc |

| Certificate | BV,SGS,MTC |

| Delivery time | Within ****0days after receiving the deposit |

2. The production process

(1) Raw material : steel strip coil, solder wire, soldering flux.All of them go through strict physical and chemical inspection before .

(2) Steel strip head and tail docking,use single or double wire submerged arc welding, after rolled steel pipe by automatic submerged arc welding repair welding.

(3) Prior to molding, strip after flattening, cutting edge, edge planing, transmission and cleaning the surface to the flanging process.

(4) The electric contact pressure gauge control conveyor side pressure of cylinder under pressure, ensure the smooth delivery of steel strip.

(5) Using external control and internal control roll forming

(6) Weld gap control device is used to ensure that meet the requirements of welding seam clearance, pipe diameter, and quantity of the wrong side of weld gap are tightly controlled.

(7) Inside welding and outside welding are used within the United States Lincoln welding machine for single or double wire submerged arc welding, to obtain the stability of the welding specification.

(8) After welding the weld passes the online continuous ultrasonic automatic meter check, ensure the spiral weld nondestructive testing coverage of **0%. If there are defects, automatic alarm and spray tags, production workers to adjust process parameters, in a timely manner to eliminate defects.

(9) Using air plasma cutting machine to cut the tube into single

(*0) After cutting into single pole, the head of every batch of steel pipe should be strictly check system, check the weld mechanical properties, chemical composition, amalgamation, steel tube surface quality and the nondestructive flaw detection, ensure that qualified pipe process, can be formally put into production.

(*1) Weld on the product to have a continuous sound wave flaw detection, after manual ultrasonic and X-ray check, if there are defects, after repair, nondestructive tested again, until confirm the defect has been eliminated.

(*2) Strip steel butt weld and spiral seam intersection of t type connectoin the tube, check all after X-ray .

(*3) Each steel pipe after hydrostatic pressure test, pressure radial seals. Test pressure and time are controlled strictly by steel pipe hydraulic computer testing device. The test parameters automatically printed out

(*4) Pipe end machining, make the end verticality, slope Angle and the blunt edge to get accurate control

3 pressure

4.Factory

5.Certificate

why choose us.

Dongpengboda(Tianjin)industrial co.,ltd. Group company three subsidiary companies: Tianjin Tianfeng Steel Pipe Co.,Ltd; Tianjin Tianwang Steel Pipe Co.,Ltd; Tianjin FWS Trading Co.,Ltd.

We have *5 production lines of galvanized square and rectangular pipe, hot rolled square and rectangular steel pipe and other various types of steel pipes.

Our products are strictly according to the international standards, they can export to North America, South America, Europe, Middle East, Southeast Asia, Australia and Central Asia

Application: greenhouses, threading pipe, steel liner tube in family decorate, construction steel structure, ship machinery, container, steel-wood furniture, bridge structure and so on.

Other products: hot dipped galvanized pipe, cold rolled steel pipe, petroleum casing pipe, seamless steel pipe, shaped pipe, galvalume steel coil, PPGI, corrugated sheet, PC strand.

The annual output is 1.4 million tons and sale reaches 4.2 billion Yuan.

| Country: | China |

| Model No: | API 5L |

| FOB Price: | 750 ~ 2500 / Ton Get Latest Price |

| Place of Origin: | - |

| Price for Minimum Order: | 750 per Ton |

| Minimum Order Quantity: | 10 Metric Ton |

| Packaging Detail: | Bulk cargo, pipe cap, steel strips bundled |

| Delivery Time: | 30-45days after receiving the deposit |

| Supplying Ability: | 1000 Ton per Month |

| Payment Type: | Western Union, D/A, L/C, T/T |

| Product Group : | round steel pipe |