FOB Price

Get Latest Price( Negotiable )

|1 Ton Minimum Order

Country:

China

Model No:

-

FOB Price:

( Negotiable ) Get Latest Price

Place of Origin:

China

Price for Minimum Order:

-

Minimum Order Quantity:

1 Ton

Packaging Detail:

-

Delivery Time:

-

Supplying Ability:

20000 Ton per Year

Payment Type:

T/T

Product Group :

Contact Person Ms. Ada

Hengtai Building, No. 316 Shangchuan Road, District 33, Baoan District, Shenzhen, China., Shenzhen, Guangdong

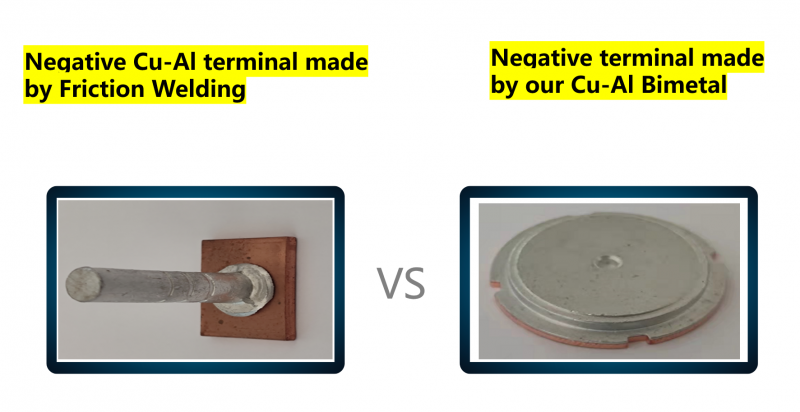

Why CATL and BYD adopt the

negative terminal for battery pack made by our Cu-Al bimetal

materials instead of previous negative terminal made by traditional

friction welding?

Production Advantages of our

new negative terminal:

1. Prepare

Cu-Al bimetal materials our company

produced.

2. Direct

Stamping on Cu-Al bimetal materials.

3. Single

machine can produce 20000pcs per day.

4. Normal

stamping machine can produce and no limit of production

capacity.

Production limit of negative

terminal made by traditional friction

welding:

1. Buy Copper

and Aluminum materials Separetely.

2. Welding

Copper and Aluminum together and more steps of

processing.

3. Single

machine can produce 7000pcs per day.

4. Only

friction welding machine can produce with limit

of production capacity.

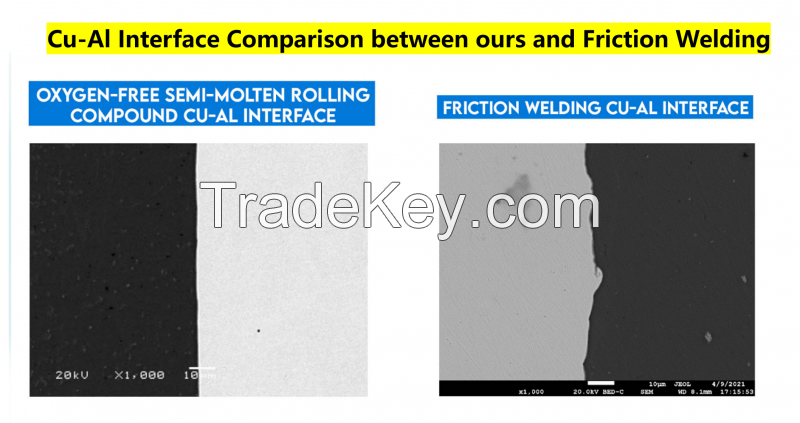

Our Copper-Aluminum Bimetal Composites material is

a plating of copper on aluminum. The two metals

are combined together through

our patented technology which we

called Oxygen-free Semi-molten

rolling compound technology. This technology

solves the technical problems of oxidation and eutectic of

copper-aluminum composite.

Copper-Aluminum Bimetal

Composites strips

Features

1. Dimensions

and allowable tolerances of copper-aluminum composite

materials

Sheet1: Strip

thickness and width and allowable

tolerances (Unit:mm )

| Serial | material code | Name | base value | allowable tolerances |

| 1 |

TY-DC0001 |

thickness | 3.8mm | +0.15/-0 |

| 2 | Copper layer thickness | 1.3mm | ±0.05 | |

| 3 | Aluminum layer thickness | 2.5mm | / | |

| 4 | Width | 40~145 | +0/-0.3 | |

| 5 | Length | / | / | |

| 6 |

TY-DC0002 |

thickness | 3.9mm | +0.1/-0.05 |

| 7 | Copper layer thickness | 1.3mm | ±0.05 | |

| 8 | Aluminum layer thickness | 2.6mm | / | |

| 9 | Width | 40~145 | +0/-0.3 | |

| 10 | Length | / | / |

| Country: | China |

| Model No: | - |

| FOB Price: | ( Negotiable ) Get Latest Price |

| Place of Origin: | China |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | 1 Ton |

| Packaging Detail: | - |

| Delivery Time: | - |

| Supplying Ability: | 20000 Ton per Year |

| Payment Type: | T/T |

| Product Group : | copper-aluminum negative terminals |