Specialized Company for Designing, Manufacturing, and Operating

Dry Ice Cleaning

Dry Ice has a higher cleaning efficiency than other cleaning

machines. It shows outstanding cleaning ability even against

hard-to-clean objects. Moreover, its maintenance and operation

expenses are cheap.

It causes no damage to the parent metal.

Key Features

1. There is a big difference in temperature.

The temperature of ice is 0°C, whereas the temperature of dry

ice is -78.5°C.

It has a very low temperature, and because it has sublimation,

which changes directly to a gas without going through a liquid

state, it absorbs the surrounding heat and lowers the

temperature rapidly.

Therefore, it is widely used as a coolant to keep the

surrounding material cold (fresh food storage, ice cream cold

storage, etc.).

2. Unlike ice, it does not contain water.

When dry ice is left outside, it sublimes and disappears

without leaving any water, which proves that there is no

moisture. For this reason, it is called Dry-Ice, which means

'dry ice'.

3.hardness is very low.

Although there is a slight difference depending on the

temperature and size, dry ice is more easily broken than ice

and has a hardness of less than or equal to gypsum (2

mohs).

4. The change of state at room temperature and pressure is very

different.

This is because ice slowly melts and turns into water, whereas

dry ice is a representative sublimable material that expands in

volume without going through a liquid state and turns into a

gas.

Product Specification

|

Safty Valve

|

9.5bar

|

Vibrator

|

30W

|

|

Hopper capacity

|

25kg

|

Blasting Hose

|

3/4"(Double Special Cloth)

|

|

Motor

|

0.5kw

|

Air supply hose

|

3/4"

|

|

Pellet consumption

|

10~60kg/h

|

Power specification

|

220V, 60Hz

|

Need for Dry ice Cleaning

Need for industrial cleaning /

decontamination

• Dirt, dust, sludge radioactive materials and pollution are

generated when handing various industrial manufacturing

processes and industrial facilities.

• Economic losses due to waste of manpower, delay in

construction delivery, and harmful substances are

generated.

• Necessity of spraying method using tools

-> Spraying : It removes scale, rust, coating film from the

base material by spraying the water with sand, steel, shot,

grit, silica and other abrasives with compressed air.

Major Injection Method Status and Issues

• Sand blasting method : Strongly spraying fine sand particles

with compressed air, etc.

-> A large number of workers suffer from silicon pneumonia

in Turkey's and spraying workshop (Hankyoreh

21-2010.07.02)

• Conventional blasting methods, such as sand blasting, cause

secondary pollutants (environmental destruction and harmful /

carcinogenic substances, etc.) and damage to the base material,

resulting in economic losses.

• It is an indispensable requirement for eco-friendly dry ice

blast cleaning to improve working environment, minimize

environmental damage and economic losses.

Dry Ice Cleaning Method and Characteristics

• Dry ice pellets with hardness of 2 Mohs are sprayed under 5

atmospheres collide with foreign substances in the speed of

300~800 m/s.

• Dry ice pellets are quickly frozen under super low

temperature and give a thermal shock from temperature

difference between cleaning target and pellets.

• Repeated shrinkage and cracking take place due to abnormal

thermal expansion coefficient of the foreign substance on the

material.

• The volume expands by 800 times due to property of dry ice

that permeated through the cracks.

• Dry cleaning is sanitary without humidity and doesn't

generate wastes or waste water causing contamination.

• In case of molds, dry ice pellets can be sprayed directly on

the machine without the need for re-setting after cleaning.

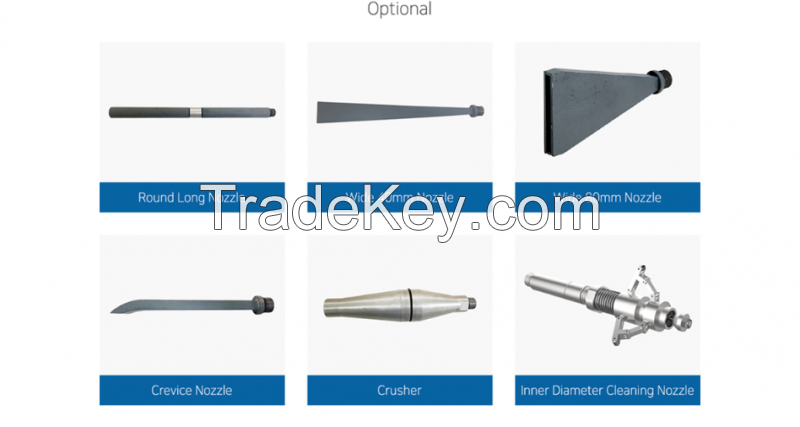

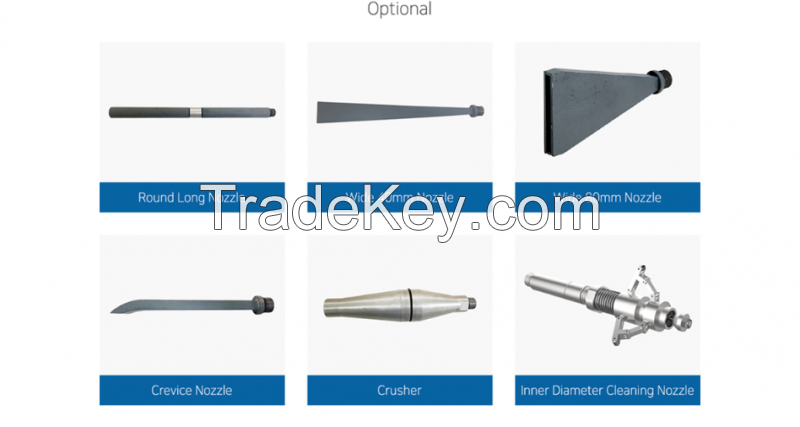

Accessory