FOB Price

Get Latest Price|

- Minimum Order

Country:

India

Model No:

-

FOB Price:

Place of Origin:

-

Price for Minimum Order:

-

Minimum Order Quantity:

-

Packaging Detail:

-

Delivery Time:

-

Supplying Ability:

-

Payment Type:

-

Product Group :

-

Contact Person Rajsekar

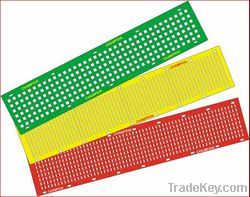

Flip Flop Flip Flow PU Screen Mats flexible

Champion Filters offer the largest range of Flip Flow Screen

Mats

Any Size - Any Aperture - Any Applicatio

We have more than **0 different moulds for these mats and have

capability of making new moulds within **3 hours maximum and can

ship around **0 nos of these mats per day.

We have automatic ovens of 6 metres long - *2 nos and a continuous

chain conveyor for uniform temperature curing.

Champion offers largest range of flip flow screens or flip flop

screen mats for classification of fine cut and near cut size

grains having high moisture content.

Flip flop or flip flow screening machines have been in operation

for decades for screening of moist or humid materials. Some typical

applications

· Iron Ore at 6mm with *5%

moisture

· Raw sand at 3mm with 6% moisture

· Compost at *0mm with *0% moisture

· Slag at 3mm with *0% moisture

· Salt at 3 mm with 5 % moisture

· Coke at 3mm with *0% moisture

· Lignite at 6mm with *0% moisture

· Coal at 6mm with *8% moisture

· Limestone at 3mm with *0% moisture

· Pet coke at 3mm with *8% moisture

· Plus other hard to screen materials like wood chips, bamboo

chips, washery waste, building rubble, soil, plastic, auto parts

etc.

Principle of Operation :

Generally referred to as “flip flow” or “ flip flop” screening

method. During the cycling of screener, the flexible mats are

individually tensioned and relaxed, which breaks or loosens the

adhesive bond within the materials, and between the material and

flip flow screen mats.

In the upstroke, the material is impelled upward functioning like a

trampoline and air is drawn in and through the material. The

motion is such that the acceleration on machine support frame could

be approx 3g whereas the material on the screen panels may

experience around *0g.

During these stretch & relax moments, the openings or aperture

in the screen mats get elongated , stretched or bend which

tremendously helps in release of particles which might have got

jammed.

Spare Screens/Mats for all machines :

Champion produces widest range of flip flow / flip flop / Feed

Impact / screen mats ready for installation on machines of all

types, sizes and manufacturers.

The screen sieve mats are made from proprietary grades of highly

resilient elastomers (including polyurethane / pu) with balanced

range of properties to withstand deformation without loss of

elasticity or dimensional accuracy.

Only high quality elastomers are used to guarantee highest

performance in terms of abrasion resistance, cut & tear

resistance, flexibility and resilience.

We make in homogenous materials and for certain specialized

applications reinforce the screens with flexible bars or cables to

meet your specific process needs.

All the characteristics of the polyurethane screens are well

defined like dimensions, thickness, blind zones, fixing holes,

hooks, shore hardness, polyurethane / pu / elastomers quality.

All apertures shapes like square / round (conical), rectangular,

tear drops, hexagonal are available.

| Country: | India |

| Model No: | - |

| FOB Price: | Get Latest Price |

| Place of Origin: | - |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | - |

| Packaging Detail: | - |

| Delivery Time: | - |

| Supplying Ability: | - |

| Payment Type: | - |

| Product Group : | - |