FOB Price

Get Latest Price|

- Minimum Order

Country:

India

Model No:

ZA-8, ZA-12, ZA-27 Foundry Alloy

FOB Price:

Place of Origin:

-

Price for Minimum Order:

-

Minimum Order Quantity:

-

Packaging Detail:

-

Delivery Time:

-

Supplying Ability:

-

Payment Type:

-

Product Group :

-

India

Contact Person Mr. Amar

Sunderpur, Varanasi, U.P.

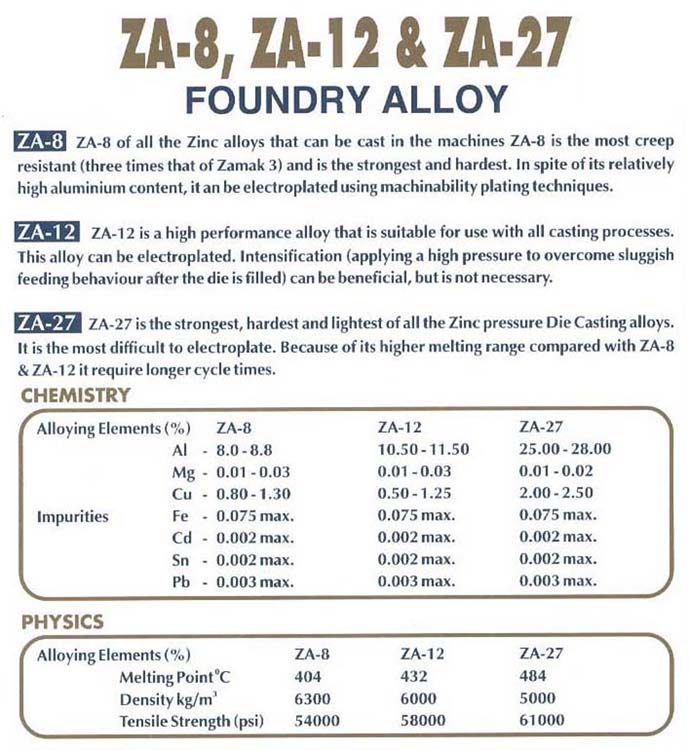

ZA*8 of all the Zinc alloys that can be cast in the machines ZA*8 is the most creep resistant (three times that of Zamak 3) and is the strongest and hardest. In spite of its relatively high aluminium content, it can be electroplated using machinability plating techniques. ZA**2 is a high performance alloy that is suitable for use with all casting processes. This alloy can be electroplated. Intensification (applying a high pressure to overcome sluggish feeding behaviour after the die is filled) can be beneficial, but is not necessary. ZA**7 is the strongest, hardest and lightest of all the Zinc pressure Die Casting alloys. It is the most difficult to electroplate. Because of its higher melting range compared with ZA*8 & ZA**2 it require longer cycle times. CHEMISTRY Alloying Elements (%) ZA*8 ZA**2 ZA**7 Al - 8.**8.8 *0.****1.*0 *5.****8.*0 Mg - 0.***0.*3 0.***0.*3 0.***0.*2 Cu - 0.***1.*0 0.***1.*5 2.***2.*0 Impurities Fe - 0.**5 max. 0.**5 max. 0.**5 max. Cd - 0.**2 max. 0.**2 max. 0.**2 max. Sn - 0.**2 max. 0.**2 max. 0.**2 max. Pb - 0.**3 max. 0.**3 max. 0.**3 max. PHYSICS Alloying Elements (%) ZA*8 ZA**2 ZA**7 Melting Point 0C **4 **2 **4 Density kg/m3 ***0 ***0 ***0 Tensile Strength (psi) ****0 ****0 ****0

| Country: | India |

| Model No: | ZA-8, ZA-12, ZA-27 Foundry Alloy |

| FOB Price: | Get Latest Price |

| Place of Origin: | - |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | - |

| Packaging Detail: | - |

| Delivery Time: | - |

| Supplying Ability: | - |

| Payment Type: | - |

| Product Group : | - |