FOB Price

Get Latest Price40000 ~ 1e+07 USD / ( Negotiable )

|1 Set Minimum Order

Country:

China

Model No:

-

FOB Price:

40000 ~ 1e+07 USD / ( Negotiable ) Get Latest Price

Place of Origin:

-

Price for Minimum Order:

40000

Minimum Order Quantity:

1 Set

Packaging Detail:

Standard packing for transportation by sea.

Delivery Time:

15days

Supplying Ability:

100 Set per Month

Payment Type:

T/T, L/C, Western Union

Product Group :

-

Contact Person Susan

Zhengzhou, Henan

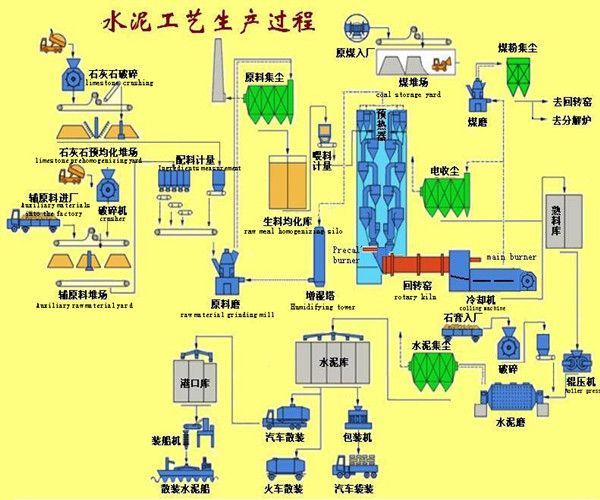

Our company is a professional making cememt manufacturer, such as ball mill, rotary kiln, roller press, belt conveyor ,raw mill, air-swept coal mill, cement kiln and vertical mill etc.

1.Crushing and Preblending

As making cememt manufacturer, most of the material

need to be broken, such as limestone, clay, iron ore and coal,

etc. Limestone is the largest amount of raw material in cement

production, after mining the size of limestone is large, with

high hardness, so the limestone crushing plays a more important

role in cement plant.

2. Raw Material Preparation

As making cememt manufacturer, in cement production, producing each 1 ton of Portland cement need grinding at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials, gypsum). Grinding operation consumes power about *0% of total power in cement plants, raw material grinding takes more than *0%, while coal mill used in cement palnt consumes 3%, cement grinding about *0%. So choosing the right grinding mills in cement plant is very important.

3. Raw Materials Homogenization

As making cememt manufacturer,we adopt the technology of homogenization could rationally get the best homo-effect and afford an eligible production to the demand.

4. Preheating and Precalcing

Preheater and calciner is key equipment for precalcing production technique.

5.Burning Cement Clinker in Rotary Kiln

Rotary Kiln is a key cement making machine , it makes directly

influence on the quality of cement clinker.

6. Cement Grinding

As making cememt manufacturer, cement grinding mill is the

vertical cement making machine that is used for grinding cement

clinker (and gelling agent, performance tuning materials, etc.)

to the appropriate size (in fineness, specific surface area,

said), optimizing cement grain grading, increasing the hydration

area, accelerating the hydration rate to meet the requirements of

cement paste setting, hardening.

All machineries from Henan Fuwei Mining Machinery Manufactory are made by ourselves, with lower price, good quality and assured full after service.

| Country: | China |

| Model No: | - |

| FOB Price: | 40000 ~ 1e+07 / ( Negotiable ) Get Latest Price |

| Place of Origin: | - |

| Price for Minimum Order: | 40000 |

| Minimum Order Quantity: | 1 Set |

| Packaging Detail: | Standard packing for transportation by sea. |

| Delivery Time: | 15days |

| Supplying Ability: | 100 Set per Month |

| Payment Type: | T/T, L/C, Western Union |

| Product Group : | - |