FOB Price

Get Latest Price50000 ~ 80000 / Set

|1 Set Minimum Order

Country:

China

Model No:

DY-12

FOB Price:

50000 ~ 80000 / Set Get Latest Price

Place of Origin:

China

Price for Minimum Order:

50000 per Set

Minimum Order Quantity:

1 Set

Packaging Detail:

Packed in the container or customer�s requi

Delivery Time:

Shipped in 25 days after payment

Supplying Ability:

25 Set per Month

Payment Type:

PayPal, Money Gram, Western Union, D/P, D/A, L/C, T/T

Product Group :

Contact Person Ms. Bonnie

Room 1408, 14th Floor, Building 9, No.133 Yaozhai Road, Jinshui District, Zhengzhou, Henan

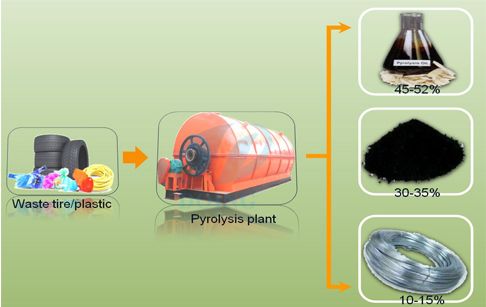

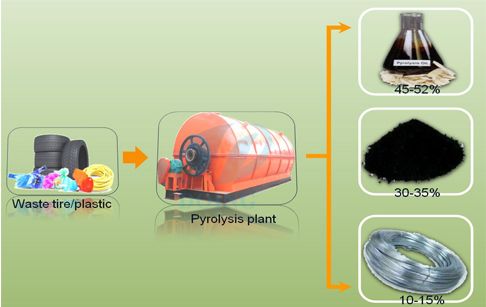

DOING GROUP are specialized in manufacturing Scrap tires for

recycling to fuel oil plant, pyrolysis plant , plastic to oil plant

and oil distillation machine, oil refining machines, tire oil /

plastic oil / engine oil / motor oil / ship oil refining plants. We

have two workshops producing each line (pyrolysis machine and waste

oil distillation machine) , professional laboratory improving

technology and demo plant which could show customers running

machine. And rich experienced engineers guarantee installation of

our equipment with good after -sale service.Waste tyre recycling

machine can convert waste tires, waste plastic, waste rubber to

fuel oil, carbon, steel wire. Waste tire oil average rate is

*5%**2%, plastic is *5%**5% for PP,PE,ABS etc.

Working process of waste tire recycling

machine:

1,Firstly, the raw material was put into furnace with

auto feeder,thenseal the feed inlet system.

2,Secondly, burned the fuel material (coal, or wood,

or natural gas, oil ) in the combustion system .The reactor will

slowly heat, when the temperature reach around **0 degree Celsius,

it will produce oil gas .

3,Oil gas will be processed by our technology ,then

gone to cooling system to cold liquid oil. The gas which can not be

liquid under normal pressure ,which will be designed to back to

combustion system to instead the fuel material to burn the reactor

.which can save energy very much.

4,After finished oil produce ,the temperature of

reactor will be down ,in same time ,carbon black will be discharged

automatically.

5,Lastly, when the temperature fall to **0 degree

Celsius, worker could opened the door of reactor to discharge of

steel wire .

6,Then can start to another batch working.

Main Parts of waste tire recycling machine :

1,Auto-feeder - To shorten feeding time; feed more raw

material; save workers,save time,save energy.

2,Reactor - Q**5R/Q**5R material , pyrolysis for waste

tire / waste plastic / waste rubber.

3,Buffer chamber - To reduce oil gas speed;

improve oil quality.

4,Oil-water separator - Avoid oil gas reback to

reactor, ensure running safety.

5,Cooling system (Vertical condensers and horizontal

condensers) ***0 squre meter better condensing effect to get

more.

6,Oil tanks - Collect tire/plastic oil.

7,Anti-back fire device - First to recycle tail gas to furnace as

fuel; second water closing for machine running safety.

8,Negative pressure device - Guarantee working under

normal pressure safety; shorten pyrolysis time; environment

protection.

9,Dust removal system - ensure the smoke reach international

emission standard.

*0,Bad mell removal system - Remove bad mell,keep a well

environmental working place, to ensure reach international emission

standard.

*1,Carbon black slagging device - Slagging carbon black

automatically, environmental protection; save time and

workers.

Productions application of waste tire recycling

machine:

Pyrolysis oil uses as substitute of furnace oil and can be used in

boiler factories, road construction unit (for making asphalt),

rolling casting unit, furnace industries, distillation units for

converting diesel,

Carbon black powder will be purchased by cement factory companies,

paint industries, rubber processing factories; it can be converted

to coal also.

Steel Scrap Wire, Scrap dealers will purchase this type of steel

scrap, so it will be sold as scrap in the market.

| Country: | China |

| Model No: | DY-12 |

| FOB Price: | 50000 ~ 80000 / Set Get Latest Price |

| Place of Origin: | China |

| Price for Minimum Order: | 50000 per Set |

| Minimum Order Quantity: | 1 Set |

| Packaging Detail: | Packed in the container or customer�s requi |

| Delivery Time: | Shipped in 25 days after payment |

| Supplying Ability: | 25 Set per Month |

| Payment Type: | PayPal, Money Gram, Western Union, D/P, D/A, L/C, T/T |

| Product Group : | pyrolysis plant |