FOB Price

Get Latest Price( Negotiable )

|1 Set Minimum Order

Country:

China

Model No:

-

FOB Price:

( Negotiable ) Get Latest Price

Place of Origin:

China

Price for Minimum Order:

-

Minimum Order Quantity:

1 Set

Packaging Detail:

-

Delivery Time:

30-60 days

Supplying Ability:

-

Payment Type:

L/C, T/T

Product Group :

-

Contact Person Ivy

Guiyang, Guizhou

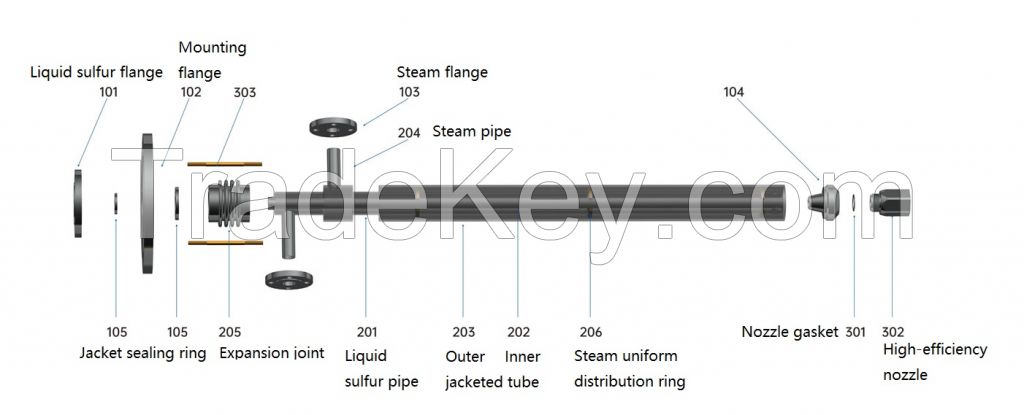

High-performance sulfur gun

As a key piece of equipment in sulfuric acid production plants using sulfur, the performance and quality of sulfur guns are directly related to the safety, environmental protection standards, and economic efficiency of the plant.

Data shows that during the operation of sulfuric acid production plants using sulfur, unplanned shutdowns caused by sulfur gun issues account for more than *0%, with their failure rate significantly higher than that of pump failures, static equipment leaks, and electrical & instrumentation faults. Sulfur gun failures may also trigger other serious problems, such as corrosion of economizers, system blockages caused by sublimed sulfur, corrosion of sulfur furnaces, and flue gas leaks, which can result in huge economic losses and prolonged shutdowns for enterprises.

The Wylton high-performance sulfur gun adopts three core technologies: gun body temperature equalization technology, straight-through flow acceleration technology, and high-diameter pressure-bearing butt welding technology, effectively solving the problems of sulfur gun bending, blockage, and leakage. This ensures that the plant will not shut down due to sulfur gun failures during long-term operation cycles, thereby avoiding economic losses for enterprises.

Advantages:

Large-scale sulfur-based sulfuric acid equipment can reduce

the number of sulfur guns installed, lower the investment

cost of liquid sulfur pipelines and auxiliary instruments,

save space on the sulfur-burning furnace platform, and reduce

the workload of sulfur gun installation during plant startup

and shutdown.

High-efficiency atomization technology improves the operating

efficiency of the sulfur-burning furnace, ensuring that

liquid sulfur combustion does not occur at the bottom of the

furnace, thereby protecting the furnace from corrosion by

sublimed sulfur and preventing the formation of sublimed

sulfur inside the system.

It features an ultra-wide atomization adjustment range, which can meet the needs of large, medium, and small-scale plants, ensuring the stability of the atomization and combustion process.

The adoption of stratified combustion technology prevents the furnace chamber temperature of the sulfur-burning furnace from exceeding ***0°C, thus effectively ensuring the safe and stable operation of the plant. The high-efficiency sulfur gun supports on-line replacement, which helps users achieve long-term stable operation of the equipment.

| Country: | China |

| Model No: | - |

| FOB Price: | ( Negotiable ) Get Latest Price |

| Place of Origin: | China |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | 1 Set |

| Packaging Detail: | - |

| Delivery Time: | 30-60 days |

| Supplying Ability: | - |

| Payment Type: | L/C, T/T |

| Product Group : | - |