Product Description

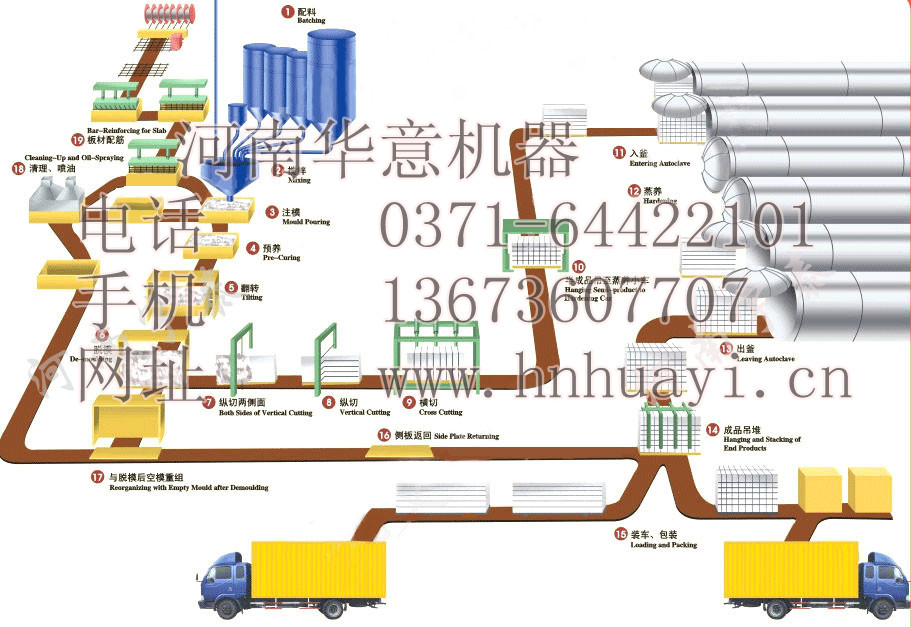

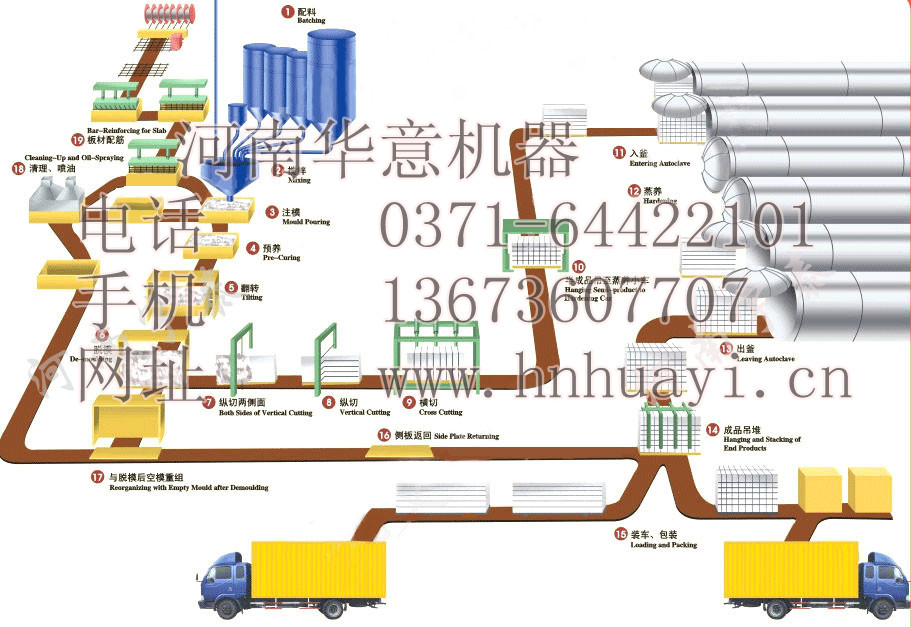

Production Process of

Aerated Concrete According to the category and quality of raw

material, and the features of equipment, the aerated concrete can

be manufactured in different processes. Generally, add water to

ash, silica sand or slag and crush them into slurry; then add

powdery lime, cement of right amount, plaster, vesicant, foam

stabilizer, and mix and pour it to mould frame; after curing,

foaming and hardening, cut it into blocks and boards in different

specifications; finally, transport it into pressure steamer with

steam-curing cart, and get the light cellular concrete after

steam-curing with high temperature and pressure. Process Flow of

an Annual Output *0,**0m******0,**0m3 Aerated Concrete

Steam-Curing Production (1) Various raw material storage

tanks→

(2) Mix

dosing→

(3) add water to raw

material and mix them→ (4) prepare the

mould→

(5)

pour→

(6) foam and

wait→

(7) release from

mould→

(8) turn up, cut

horizontally and vertically→ (9) make into groups and get into

autoclave→ (*0) cureunder high temperature and

pressure→ (*1) release the finished

products from the autoclave→ (*2) test the finished

products→ (*3) pack→ (*4) stack and store

up→

(*5) leave the

factory The specific production flow is as

follows:。

aerated

concrete equipment details:

Aerated concrete products in the overseas development up to now

for nearly a century of history has become a pillar industry in

the construction industry, China's introduction of the technology

may be close to four decades, the production processes and

equipment and equipment to mature.The aerated concrete is

characterized by the advantages of light weight, heat

preservation, sound isolation, high strength,processable property and so

on,the raw

materials ofaerated concrete

products are

abundant.,Especially, it can not only

make use of industrial waste residue, improve environmental

pollution, and protect tillable field, but also create favorable

social and economic benefits to take fly ash as the raw material

of AACblock and board. Aerated concrete is the perfect wall

material to replace the traditional solid clay brick. For many

years, Aerated Concrete (AAC) has always accepted strong supports

from the policies about reforming of wall material, tax policies

and environment protection policies. Aeroconcrete (AAC) block and

board have become the important part of new-type construction

materials, and possess broad prospect of development..

| Country: |

China |

| Model No: |

new

|

| FOB Price: |

(Negotiable)

Get Latest Price

|

| Place of Origin: |

50 |

| Price for Minimum Order: |

- |

| Minimum Order Quantity: |

1 |

| Packaging Detail: |

- |

| Delivery Time: |

- |

| Supplying Ability: |

1 |

| Payment Type: |

- |

| Product Group : |

- |