FOB Price

Get Latest Price|

- Minimum Order

Country:

China

Model No:

OB1

FOB Price:

Place of Origin:

China

Price for Minimum Order:

-

Minimum Order Quantity:

-

Packaging Detail:

Carton

Delivery Time:

4 Working days

Supplying Ability:

-

Payment Type:

-

Product Group :

-

Contact Person Sophie

Hongli Road, Dongguan, Guangdong

ABOUT OPTICAL BONDING

Originally developed for avionics and military displays,

optical bonding is now moving into industrial and consumer

applications such as touch screens, TVs, smartphones, digital

signage and medical imaging.

Optical bonding (LCD bonding, direct bonding) refers to a

protective glass or touchscreen that is glued in front of a

display to enhance its readability in high humidity outdoor

environments. When a normal display is used in an outdoor

environment, there are some factors that affect its

readability. The most common one is "fog", or condensation,

which forms on the inner surface of display's vandal shield.

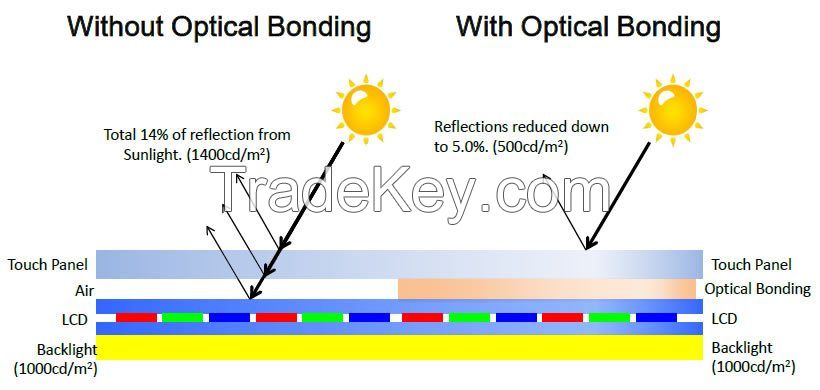

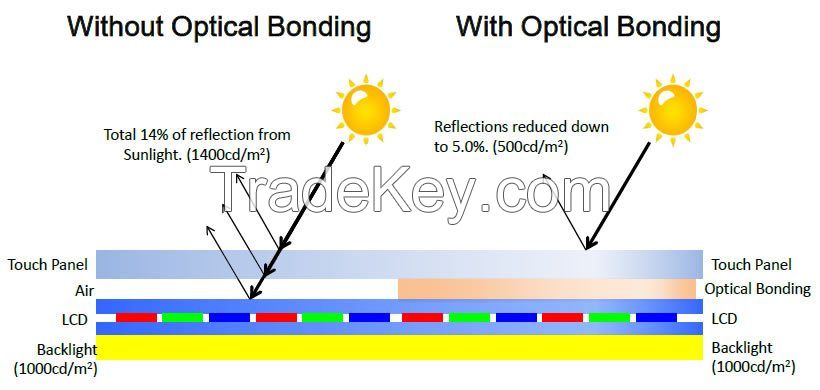

Another factor is the reflection of sunlight, which causes a

mirror-image on the display. Both phenomena can be solved by

using optical bonding.

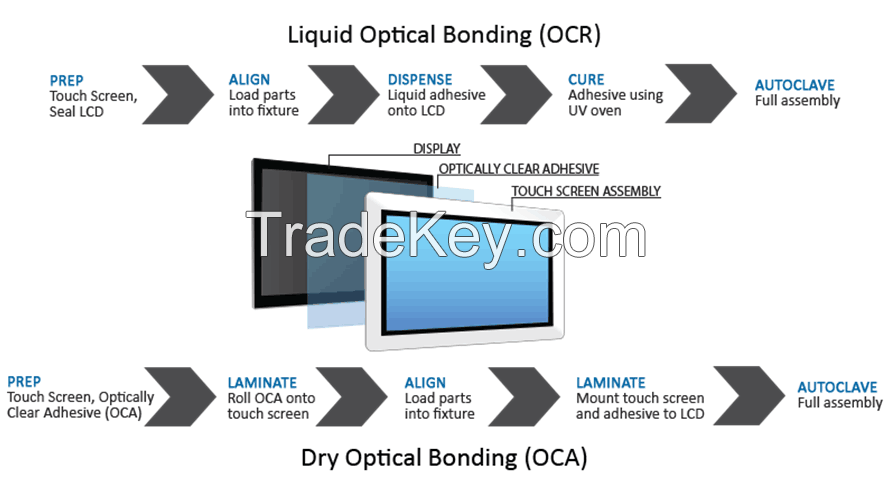

Optical bonding is the use of an optical-grade silicon-based

adhesive to glue a glass or touchscreen to the top surface of a

display. The assembly is cured in a process that affixes the

display together while solidifying the adhesive. The main goal

of optical bonding is to improve the display performance under

outdoor environments. This method eliminates the air gap

between the cover glass and the display. Moreover,

anti-reflective coating is often used in optical bonding glass.

The real problem for display readability in outdoor

environments is not the display's brightness but its contrast.

Contrast means the ratio of the white level to the black level;

in other words, the contrast ratio of display means the

difference of light intensity between the brightest white pixel

and the darkest black pixel. The main purpose of optical

bonding is to increase the display's contrast ratio by reducing

the amount of reflected ambient light.

• Increased Ruggedness (up to **0%): Bonding a sheet of glass

on top of the display increases the ruggedness of the

display.

• Improved Durability: A bonded display is better able to

resist scratches, fluids, stains and dirt.

• Condensation: The elimination of an air gap between the

cover glass and the display means that moisture cannot

Penetrate and cause fogging on display's surface.

• Increased Sunlight Readability (up to **0%): By reducing

the amount of reflection, the contrast of the bonded display

is enhanced. The higher the contrast, the easier it is to

read to display screen.

• Extended Temperature Range and EMI Filtering: The

temperature range of the display can be extended by

incorporating ITO heaters on the cover glass; EMI filters can

be added via the same mechanism.

| Country: | China |

| Model No: | OB1 |

| FOB Price: | Get Latest Price |

| Place of Origin: | China |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | - |

| Packaging Detail: | Carton |

| Delivery Time: | 4 Working days |

| Supplying Ability: | - |

| Payment Type: | - |

| Product Group : | - |