FOB Price

Get Latest Price( Negotiable )

|100 Unit Minimum Order

Country:

China

Model No:

-

FOB Price:

( Negotiable ) Get Latest Price

Place of Origin:

china

Price for Minimum Order:

-

Minimum Order Quantity:

100 Unit

Packaging Detail:

-

Delivery Time:

7 days

Supplying Ability:

500 Unit per Week

Payment Type:

T/T, L/C, Western Union, Money Gram

Product Group :

Contact Person Mr. Weili

No.28Road Zhennan Huangze Shengzhou Shaoxing Zhejiang, Zhejiang, Other

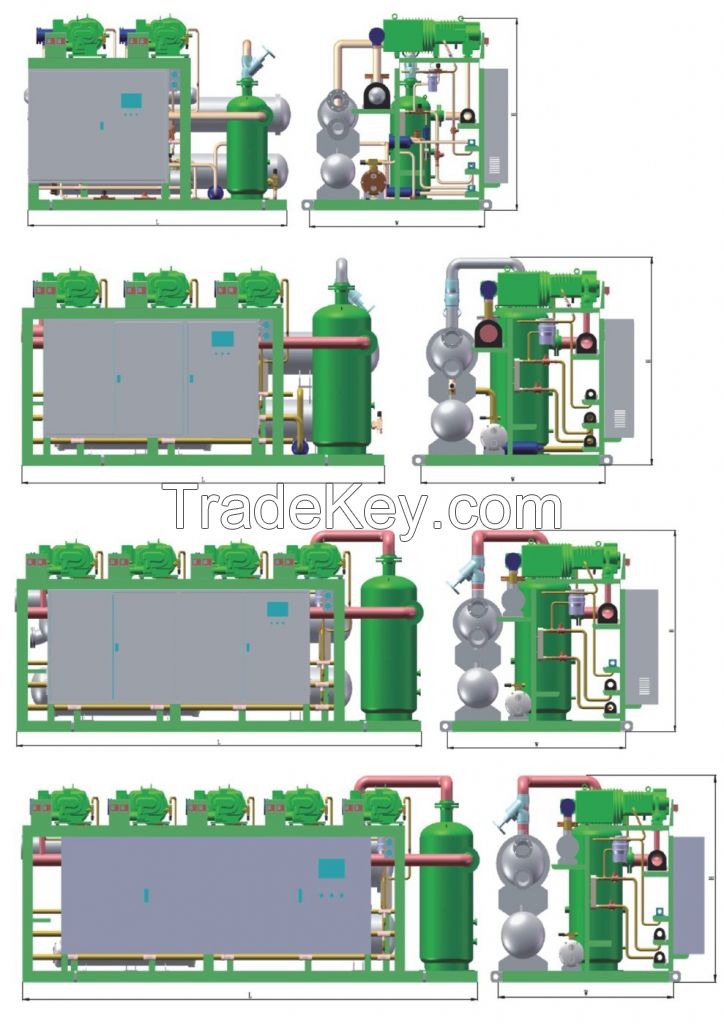

Parallel compressor

series:

Parallel compressor series

1.High quality and high performance/price ration famous brand

compressor

2.Hew type separation system,the efficiency is 99%,after startup,you do not need to lubricate.

3.Unique winter condensing pressure constant control

system,eliminate the

phenomenon of feed liquid and compressor oil short supply in

winter.even in the cold winter of Manchu,it can also maintain a condensing

pressure of 12 BAR.

4.The standard is that every set goes out with a computer control

panel,automatically

regulats compressor running time,prolong the service life.

5.The standard is that every set goes out including:phase-lacking,negative phase sequence,over voltage,under voltage,oil pressure,high pressure,low pressure,electronic type low liquid

level,electronic type

motor overload,the whole

safety protection module.

6.Unique secondary separating liquid Separation design,utmost avoid liquid collision.

7.Reserve far end alerting output wiring point,convenient for customers to

control.

High efficient,saving

energy

1.Can match different sized compressors,provide more adjustment

degrees,output cooling

capacity can dynamically match actual charge more smoothly.

2.Computer control panel adjust best curve under daily load

circumstance,save a large

amount of electric energy for terminal user.

3.Pipe design,reduce the

temperature loss to the minimum,and raise the efficiency.

4.With high efficient oil separator,only a small amount of lubricating

oil goes into the system,improve the heat exchanger

efficiency.

5.When raising the temperature of cold storage,it also reduces the evaporator

moisture load,decreases

the time and amount of defrost,raise the system efficiency.

6.Can adopt hot fluorine defrost plan,,reduce the electric

energy,save more

energy.

Compact,light

1.Several compressors share oil separator,gas-liquid separator,liquid receiver,control system and frame.

2.Provide modularized installation idea,reduce copper pipe loss,shorten the construction period.

3.Smaller installation space can provide supermarkets and cold

storage with larger commercial space,create more value for

user.

Accurate temperature

1.Micro computer control parallel compressor,real-time match

dynamic load,obviously reduce pressure fluctuation.

2.Automatic pressure regulation device,precise temperature

control,constant temperature difference,ensure accurate relative

humidity.

Parallel

compressor series

Parallel

compressor series

1.High quality and high performance/price ration famous brand

compressor

2.Hew type separation system,the efficiency is 99%,after startup,you do not need to lubricate.

3.Unique winter condensing pressure constant control

system,eliminate the

phenomenon of feed liquid and compressor oil short supply in

winter.even in the cold winter of Manchu,it can also maintain a condensing

pressure of 12 BAR.

4.The standard is that every set goes out with a computer control

panel,automatically

regulats compressor running time,prolong the service life.

5.The standard is that every set goes out including:phase-lacking,negative phase sequence,over voltage,under voltage,oil pressure,high pressure,low pressure,electronic type low liquid

level,electronic type

motor overload,the whole

safety protection module.

6.Unique secondary separating liquid Separation design,utmost avoid liquid collision.

7.Reserve far end alerting output wiring point,convenient for customers to

control.

High efficient,saving

energy

1.Can match different sized compressors,provide more adjustment

degrees,output cooling

capacity can dynamically match actual charge more smoothly.

2.Computer control panel adjust best curve under daily load

circumstance,save a large

amount of electric energy for terminal user.

3.Pipe design,reduce the

temperature loss to the minimum,and raise the efficiency.

4.With high efficient oil separator,only a small amount of lubricating

oil goes into the system,improve the heat exchanger

efficiency.

5.When raising the temperature of cold storage,it also reduces the evaporator

moisture load,decreases

the time and amount of defrost,raise the system efficiency.

6.Can adopt hot fluorine defrost plan,,reduce the electric

energy,save more

energy.

Compact,light

1.Several compressors share oil separator,gas-liquid separator,liquid receiver,control system and frame.

2.Provide modularized installation idea,reduce copper pipe loss,shorten the construction period.

3.Smaller installation space can provide supermarkets and cold

storage with larger commercial space,create more value for

user.

Accurate temperature

1.Micro computer control parallel compressor,real-time match

dynamic load,obviously reduce pressure fluctuation.

2.Automatic pressure regulation device,precise temperature

control,constant temperature difference,ensure accurate relative

humidity.

| Country: | China |

| Model No: | - |

| FOB Price: | ( Negotiable ) Get Latest Price |

| Place of Origin: | china |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | 100 Unit |

| Packaging Detail: | - |

| Delivery Time: | 7 days |

| Supplying Ability: | 500 Unit per Week |

| Payment Type: | T/T, L/C, Western Union, Money Gram |

| Product Group : | Compressor |