FOB Price

Get Latest Price6.3 ~ 7 USD / Kilogram ( Negotiable )

|200 Kilogram Minimum Order

Country:

China

Model No:

-

FOB Price:

6.3 ~ 7 USD / Kilogram ( Negotiable ) Get Latest Price

Place of Origin:

-

Price for Minimum Order:

6.3 per Kilogram

Minimum Order Quantity:

200 Kilogram

Packaging Detail:

Plastic bottle and Carton

Delivery Time:

7~15 days after payment received

Supplying Ability:

8000 Ton per Year

Payment Type:

L/C, T/T

Product Group :

-

Contact Person Eva

NO.2, Yusi Road, High-Tech Development Zone,, Quzhou, Zhejiang

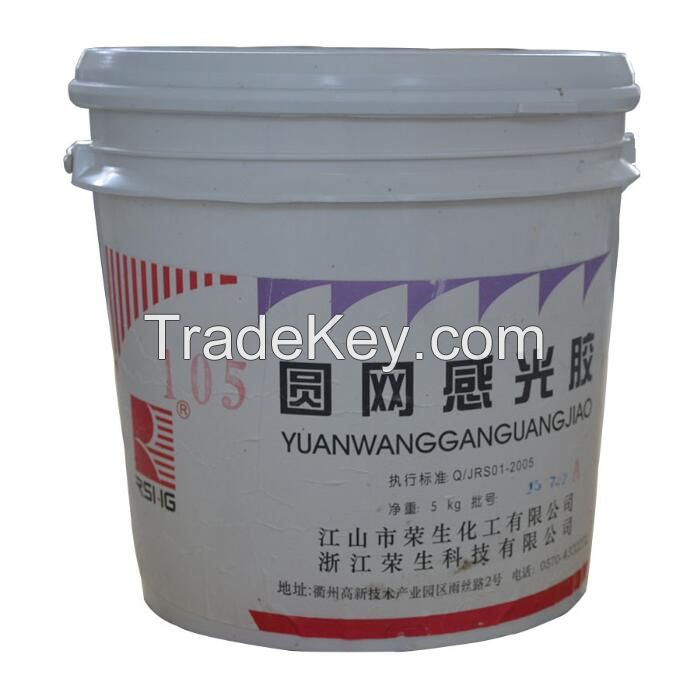

Photo Emulsion for Rotary Screens

Printing

Features and Usages

~1.Blue (or milk white)emulsion,used for rotary printing of

blue-ray machine;

2.Low curing temperature,short curing time,wide exposure

latitude,good durability,high resolution,accurate plate making,can

check the screen printing plate easily;

3.Apply to squeegee or magnetic rotary screen printing machine in

printing and textile industry;

Packing

Washing the screen:Immerse the screen into Cleaning Liquor for Nickel Screen for around *0 minutes,take out and rinse with water,then dried at low temperature in an oven. At the same time, prevent the screen from being stained with dirt(It is necessary for operators to wear protective gloves avoiding corrosiveness).

Preparing the sensitized emulsion: It should be operated under a gentle yellow light(Prohibit from operating in no opacifying condition).Put *0~*0lm photosensitizer into 1kg sensitized emulsion and stir clockwise until balance.After stirring, there will appear bubble, so you need to put it in a low temperature and dark place for 1~2 hours until the bubble is gone. Then maintain the prepared sensitized emulsion at 5~*5℃ in a constant temperature storage box(a seal cover is needed to avoid skinning and dust).

Coating: **0g of prepared emulsion is added in to a clean scraper ring and coated on the clean screen with a speed of *0~*5cm/min,then dried at *5~*0℃ and relative humidity in an oven with circle wind for *0~*0 minutes without no more than ±2℃ temperature differences.

Exposure: Fixed the coated screen on an exposure machine and fit the manuscript closely. The fit time should be determined after trial. Reference time: **8 times on a scanning machine or **3 minutes on a stationary exposure machine.

Development: The exposed screen should develop timely by putting it in water at ***0℃ for about **5 minutes, then washed until patterns appear clearly, then rinse off the leaked emulsion with water under low pressure, and dried in a constant temperature oven.

Retouching: Inspect the dried screen on an examination shelf. It is necessary to retouch the stencil with repair emulsion for rotary screen printing plate if there are blister, pattern leakage or screens stoppers.

Curing:Curing the retouched screen at **0℃ for about 2 hours in a constant temperature oven box until the surface of the emulsion becomes golden. Then take it out to bind with end-ring after cooling down.(Note: because different sensitized emulsion with different curing time and curing temperature, so it should according to the manual)

Binding the end ring: Before binding the end ring, you should use fine polishing paper to polish the bonding surface at the end of screen and end ring, then wash it with acetone or absolute alcohol, after dried put it on End Ring Gluing Machine, gluing the end ring adhesive evenly on the inner wall of screen(2cm) and end ring surface, so that they can bond. Remove the needless adhesive layer, heat curing it at **0℃ in a oven box after heat curing at *****0℃ for ****0 minutes or curing in a normal temperature.(Note: different end ring adhesives with different process conditions, so it should according to the manual)

| Country: | China |

| Model No: | - |

| FOB Price: | 6.3 ~ 7 / Kilogram ( Negotiable ) Get Latest Price |

| Place of Origin: | - |

| Price for Minimum Order: | 6.3 per Kilogram |

| Minimum Order Quantity: | 200 Kilogram |

| Packaging Detail: | Plastic bottle and Carton |

| Delivery Time: | 7~15 days after payment received |

| Supplying Ability: | 8000 Ton per Year |

| Payment Type: | L/C, T/T |

| Product Group : | - |