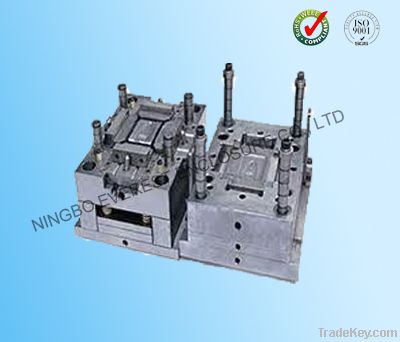

Product Description

Secification of

moulds

1. The main components of perform molds :S**6 material (Sweden

ASSAB) , **8 or H*3. 2. The mold base: P*0, (Plate

method avoids corrosion efficaciously and assures long life

service of the perform molds).

3. Lead time for mould

3~7 Weeks;

4. Product material: ABS,

PP ,PC,PC+GF, PET, PVC,HDPE etc

5. Mould life time:

*****0~1,**0,**0 shots.

Mould

Features

1. No cutting of valve gate is employed to reduce the labor

cost.

2. Advanced hot runner system assures lower level of AA

value.

3. Reasonable- designed cold water channels increase cooling

effect and shorten the cycle time.

4. Good vacuum stove is imported

for heat treatment of the components, which assures the hardness

of components HRC**-HRC*8.

5.HASCO,DME.MEUSBURGER,JIS

Standard

Our advantage

1. Capacity of Research and

Development

Everest has a powerful team for research and development, which

is capable of manufacturing the injection and die-casting molds

with one cavity to Multi- cavities. At the same time we can

manufacture perform molds especially according to customers'

injection molding machines. We also have the service to

manufacture the products by the moulds, such as electronic

enlcosures, junction boxes, tool case, equipment case,plastic

parts,etc..

2. Advanced Processing Equipment

Many machine tools are imported from America and Japan, such as

Machine center, CNC lathers, EDM and so on. All of these

increases processing precision, good interchangeability and low

eccentricity

3. Perfect Inspection Method.

Inspection tools include projector, hardness tester, stress

tester, eccentric tester, electric balance and other inspection

tools.

The screw neck is made and inspected strictly by the standard of

Coca cola and the screw neck has been up to the standard of Coca

cola.

4. After-Sales Service

Technologists professional in after-sales line and excellent

credit assures stable operation of the machines.

Process:

1. Quote

competitive price according to customer's detailed requirement.

2. Sign

agreement.

3. Customer

T/T deposit to us to start to design mould.

4. Send

mould drawing to customer for confirmation.

5. Mould

design confirmed and start to make mould.

6. Make

mould trial during tooling time ( Which we get agreement with

customer).

7. Send

mould trial sample to customer for inspection. Or customer come

to our factory to inspect mould personally.

8. Customer

T/T balance to us after mould confirmed.

9. Deliver

mould after get balance

| Country: |

China |

| Model No: |

M001

|

| FOB Price: |

5000 ~ 20000 / Set ( Negotiable ) (Negotiable)

Get Latest Price

|

| Place of Origin: |

China |

| Price for Minimum Order: |

5000 per Set |

| Minimum Order Quantity: |

100 Set |

| Packaging Detail: |

wooden package or as request |

| Delivery Time: |

3~7 Weeks |

| Supplying Ability: |

100 Set per Month |

| Payment Type: |

T/T, Western Union |

| Product Group : |

Mould

|