FOB Price

Get Latest Price500 ~ 2000 USD / Set ( Negotiable )

|1 Minimum Order

Country:

China

Model No:

-

FOB Price:

500 ~ 2000 USD / Set ( Negotiable ) Get Latest Price

Place of Origin:

Liyang,Jiangsu

Price for Minimum Order:

500 per Set

Minimum Order Quantity:

1

Packaging Detail:

Wooden box

Delivery Time:

7-10 days

Supplying Ability:

15 Set per Month

Payment Type:

T/T, L/C, Western Union, PayPal, Other

Product Group :

-

Contact Person Mr. Nathan

Jingwu, Changzhou, Jiangsu

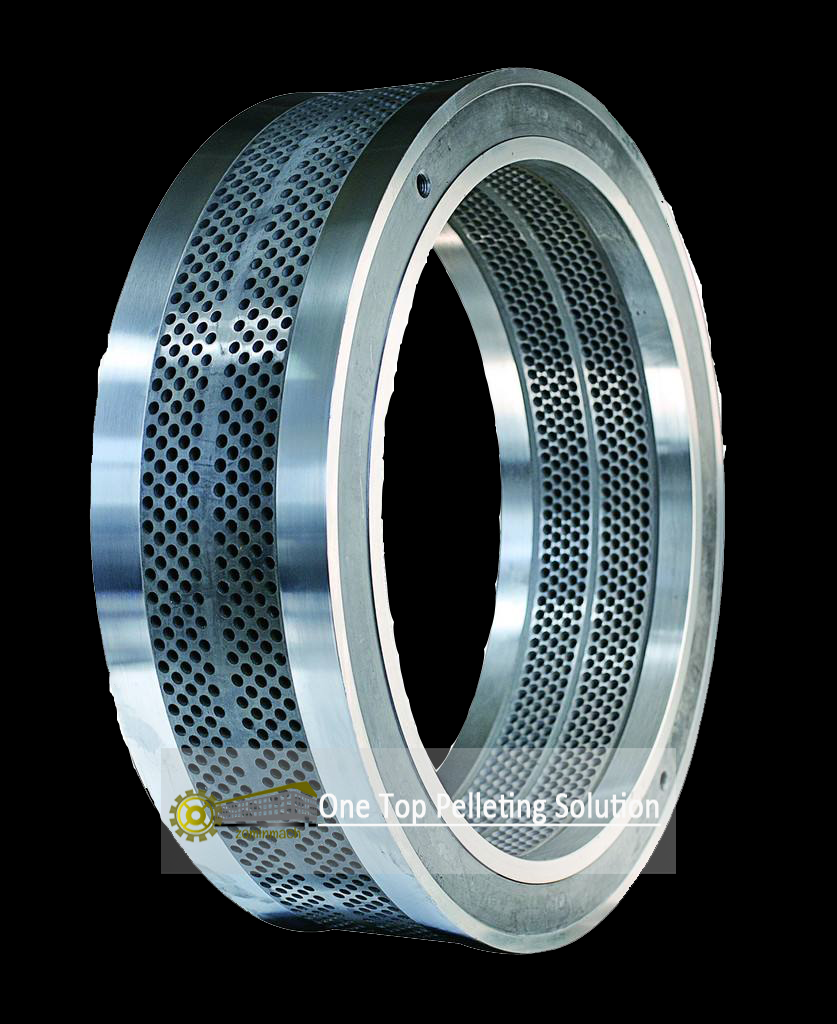

In pellet production, the ring die is a major part of pellet

production, and it is also a vulnerable part of the ring die pellet

machine, and its quality will directly affect the quality and

output of the pellets.

Force analysis of ring die of pellet machine

When the ring die pellet machine is working, the direction of the

pressing force of the pressing roller on the ring die is from the

inside to the outside along the diameter of the ring die. The inner

ring surface of the ring die receives the friction force of the

pressing roller, and the direction of the pressing roller of the

material to the ring die is along the diameter of the ring die.

From the inside to the outside, the side pressure of the raw

material on the die hole wall, the inner ring surface of the ring

die is subjected to the squeezing friction force of the material;

and in the pressure roller area, the ring die will be subjected to

the static friction force brought by gravity and the material.

The ring die carries the material in the die hole to make a rotary

motion, which will be subjected to the squeeze friction of the

pressure roller and the material. The normal failure mode of the

ring die is the excessive wear of the discharge hole, the inner

ring working surface or the ring die cracking.

The quality of the ring die and the length of its life span are

largely related to the quality of the raw materials, in addition to

the design, manufacturing, and heat treatment. Due to the high cost

of ring dies, we will compromise on wear resistance, corrosion

resistance and toughness when choosing ring dies.

Ring die materials on the market generally use alloy steel and

stainless steel, so today Bao Shell will focus on alloy steel ring

die, stainless steel ring die and the difference between the

two.

Alloy steel ring die

Alloy steel: In addition to iron and carbon, other alloying

elements are added to the steel. The iron-carbon alloy formed by

adding an appropriate amount of one or more alloying elements on

the basis of ordinary carbon steel increases the surface hardness

of the ring die; the core material has low carbon content, is

softer, and has high impact resistance Ability, not easy to crack;

but poor corrosion resistance; after the hardened layer of the

surface is worn, it wears more quickly in the later stage of

use.

The main material of alloy steel ring die is *0CrMnTi low-carbon

carburized alloy steel. The processing hardness is above HRC*0 and

has good comprehensive mechanical properties. The ring die made of

this type of material has high strength and toughness, and good

hardenability, but the disadvantages are The corrosion resistance

is not good.

Stainless steel ring die

Stainless steel (Stainless Steel) is the abbreviation of stainless

and acid-resistant steel. Steels that are resistant to weak

corrosive media such as air, steam, and water, or are stainless

steel are called stainless steel. It contains 0.4%~0.5% carbon and

*2%~*4% chromium. It has strong corrosion resistance. The hardness

from the surface of the ring die to the core is more uniform, but

the wear resistance and toughness are worse than that of alloy

steel.

Stainless steel ring die materials include German stainless steel

X*6Cr*3, domestic stainless steel 4Cr*3, etc. These materials have

good stiffness and toughness. The heat treatment is overall

quenching, the hardness is greater than HRC*0, and it has good wear

resistance and corrosion resistance, and has a long service life.

The cost of ring die for ton material is lowest.

The difference between alloy steel ring die and stainless steel

ring die

1. The corrosion resistance of alloy steel ring die is worse than

that of stainless steel ring die

2. The wear resistance and toughness of alloy steel ring die are

better than stainless steel ring die

3. The cost of alloy steel ring die is lower than that of stainless

steel ring die

How to correctly choose the material of ring die

When selecting the ring die, we should choose it reasonably

according to the pressing material, the precision of the ring die,

the working intensity and the economic benefits of the

enterprise.

1. The corrosiveness of materials: chemical additives, salt and

other corrosive media in raw materials such as aquatic livestock

and poultry feed, fertilizers, etc., have a greater corrosive

effect on the ring die. The stainless steel ring die can perform

better than the alloy steel ring die. ,increase output.

2. The hardness of the pressed material: Because the raw materials

such as sawdust, sawn wood and straw contain more impurities, the

raw material has high hardness, and the carbon content in alloy

steel is lower, and it is soft, has higher impact toughness, and

has higher abrasion resistance than stainless steel. Good, the use

of alloy steel ring die is not easy to cause the ring die to

crack.

3. Working strength of ring die: The greater the strength of the

ring die, the smaller the opening rate. The opening rate of the

forage, straw, wood chips and other materials with high extrusion

force is smaller than that of the feed ring die. Alloys can be

selected. Steel ring die; and stainless steel ring die is

recommended for high precision, small ring die hole and deep

hardened layer.

4. Ring die price: The price of stainless steel ring die with the

same compression ratio and caliber is much higher than that of

alloy steel ring die. However, the quality assurance time and the

service life of the stainless steel ring die are unmatched by the

alloy steel ring die, and the overall operating cost is lower than

that of the alloy steel ring die.

When choosing a ring die, we also need to pay attention that

frequent replacement of the die will affect the use time of the

ring die and the production output of the pellet machine. Only by

choosing the ring die reasonably, and through correct use and

effective maintenance, can the production efficiency be improved

and the production cost reduced.

| Country: | China |

| Model No: | - |

| FOB Price: | 500 ~ 2000 / Set ( Negotiable ) Get Latest Price |

| Place of Origin: | Liyang,Jiangsu |

| Price for Minimum Order: | 500 per Set |

| Minimum Order Quantity: | 1 |

| Packaging Detail: | Wooden box |

| Delivery Time: | 7-10 days |

| Supplying Ability: | 15 Set per Month |

| Payment Type: | T/T, L/C, Western Union, PayPal, Other |

| Product Group : | - |