FOB Price

Get Latest Price100000 ~ 200000 USD / Set

|1 Set Minimum Order

Country:

China

Model No:

Rotary Kiln Tyre and Rotary Kiln Support Roller

FOB Price:

100000 ~ 200000 USD / Set Get Latest Price

Place of Origin:

-

Price for Minimum Order:

100000 per Set

Minimum Order Quantity:

1 Set

Packaging Detail:

-

Delivery Time:

30 days

Supplying Ability:

1000 Set per Month

Payment Type:

L/C, T/T

Product Group :

Contact Person Mr. NEO

99 Hengshan Road, Jianxi District, Luoyang, Henan

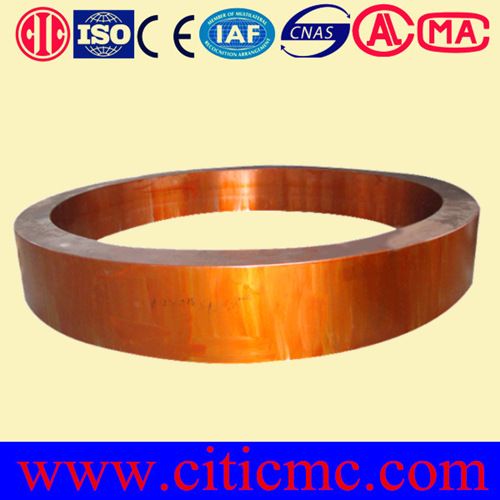

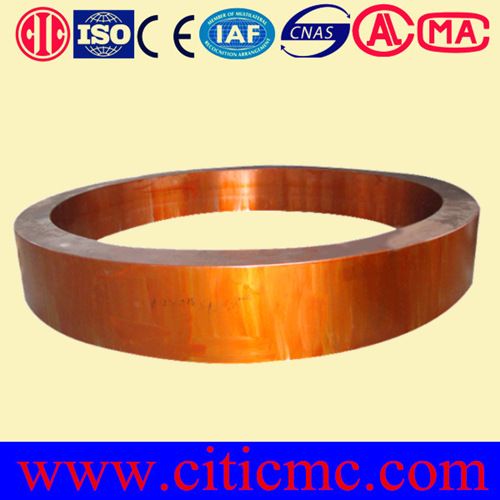

Rotary kiln tyre / supporter rollers problems and sollution methods. Rotary Kiln Tyre:

1. Material: Alloy Steel Cabon steel etc. Casting or Forging

2. Max.OD in our business line: within *6,**0mm

3. According to drawings and specifications

4. ISO********8 Certificate

5. Tyre can be used for industrial purpose, and especially used on mill, rotary kiln and so on.

We supply following Rotary Kiln Tyre reports for the customers:(1) Mechanical Test Report

(2) Hardness Test Report

(3) Chemical Test Report

(4) Heat Treatment Record

(5) Magnetic Particle Examination Report

Rotary Kiln Tyre Quality assurance:

1. Chemical checking in the Qualified Lab

2. NDE after Rough Machining

3. Mechanical testing after Heat Treatment

4. Final NDE, Dimensions check

The first rule of operating a rotary kiln without any problem is distributing the forces equally to each piers. This can be done best, by full contact on ring and supporter roller surfaces and minimum ovality in kiln shell.

As known; rotary kilns work in %3 4 slope depended on design, model and brand. This slope determines the final products specifications with turn speed, additive materials and thermo-conditions. A facility wants to present the best product to its customers in this formula.

There is a direct proportion between energy / staff / working hours and kiln problems. It means by the time you have more problems on rotary kilns, you need more energy to operate the kiln in normal conditions, more staff and more working hours to solve the technical problems.

|

Kiln Support Roller

Assembly

|

|

Defect

|

Causes

|

|

Unfilled sections

|

Insufficient material

Low pouring temperature

|

|

Porosity

|

Melt temperature is too high

Non-uniform cooling rate

Sand has low permeability

|

|

Hot tearing

|

Non-uniform cooling rate

|

|

Surface projections

|

Erosion of sand mold interior

A crack in the sand mold

Mold halves shift

|

| Country: | China |

| Model No: | Rotary Kiln Tyre and Rotary Kiln Support Roller |

| FOB Price: | 100000 ~ 200000 / Set Get Latest Price |

| Place of Origin: | - |

| Price for Minimum Order: | 100000 per Set |

| Minimum Order Quantity: | 1 Set |

| Packaging Detail: | - |

| Delivery Time: | 30 days |

| Supplying Ability: | 1000 Set per Month |

| Payment Type: | L/C, T/T |

| Product Group : | spare parts |