FOB Price

Get Latest Price|

- Minimum Order

Country:

China

Model No:

-

FOB Price:

Place of Origin:

-

Price for Minimum Order:

-

Minimum Order Quantity:

-

Packaging Detail:

-

Delivery Time:

-

Supplying Ability:

-

Payment Type:

-

Product Group :

Contact Person Mr. John

North Longquan Road,Fangqiao Industrial Zone,Yixing, Wuxi, Jiangsu

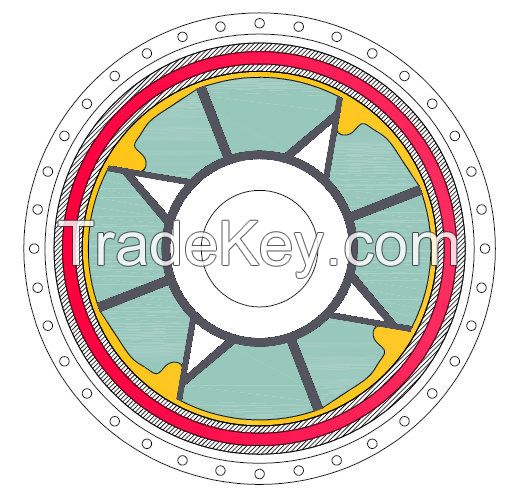

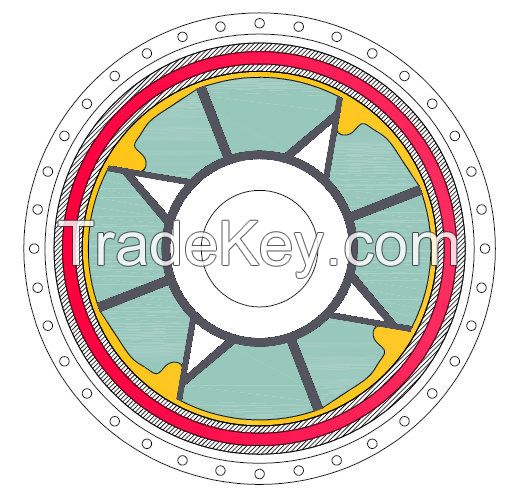

Wiped film evaporator consists of a mechanical rotating device (rotor) consisting of an evaporator, to ensure uniform distribution of the liquid on the heat transfer surface, with the film formation of turbulence, thus reinforcing the heat transfer. We can provide different types of rotors.

Thin Film Evaporators, which are also frequently called wiped film evaporators or agitated thin film evaporators have become a generally recognised and accepted solution for difficult and demanding process problems in the areas of distillation, concentration, degassing, drying and reactions.

Features

Thin Film Evaporators differ in the following main technical

features from other evaporator types:

> Continuous and trouble-free processing of viscous, fouling

and contaminated fluids by high turbulence in the liquid film,

which also reduces the required temperature difference accross

the heating surface;

> Gentle product treatment because of the short residence time

and the narrow residence time spectrum in the whole

equipment;

> High evaporation performance because of high surface heat

flux;

> High evaporation ratio in a single pass;

> Minimum losses in case of product change because of the low

hold-up.

Vertical Thin Film Evaporators Working Pinciple

The product to be treated is continuously fed into the vertical

Thin Film Evaporator above the heating jacket and is spread

on to the periphery by the distribution ring. The product is then

picked up by the rotor blades and immediately formed in to a thin

turbulent film on the heat transfer surface.

The volatile components of the feed stock are therefore very

quickly evaporated and flow counter-currently with reference to

the feed, up towards the top of the evaporator to the rotating

separator. Here, entrained droplets or foam are knocked out of

the vapour steam and return to the evaporation zone. The

evaporated components (low boilers) then flow out of the

evaporator in to the condensation stage, column or to another

downstream process step. For special applications co-current

vapour/product flow can be used in which case a separation vessel

is fitted at the bottom of the evaporator below the rotor in

place of the normal rotor mounted separator and the upper vapour

outlet nozzle.

Application areas:

In the heat exchange projects, wiped film evaporator to obtain a

wide range of applications. In particular ( short time ) heat

exchange for heat-sensitive materials , scraping the film is

conducive to the exchange of heat and scrape through different

membrane design , capable of distilling complex products .

Wiped film evaporator is used in the following areas have been

concentrated by evaporation , precipitation , stripping reaction

, degassing, deodorant ( gas ) for the purpose flavor , achieved

good results :

In medicine : antibiotics, tripterygium , astragalus and other

herbs , methylimidazole, single nitrile amines and other

intermediates ;

Light food : fruit juice , gravy, colors, flavors , fragrances ,

enzymes , lactic acid, xylose , starch, sugar , potassium sorbate

;

Cosmetic oils : lecithin , VE, cod liver oil , oleic acid,

glycerol , fatty acids, waste lubricating oil , alkyl

polyglycosides , alcohol sulfates ;

Synthetic resin : polyamide resin , epoxy resin, paraformaldehyde

, PPS ( sebacic acid esters of polypropylene ), PBT, acrylic acid

esters ;

Synthetic : PTA, DMT, carbon fiber , polytetrahydrofuran

polyether polyol ;

Petrochemical : TDI, MDI, trimethyl hydroquinone ,

trimethylolpropane , sodium hydroxide, etc. ;

Bio- pesticides : acetochlor, metolachlor , chlorpyrifos , furan

phenol , Clomazone , such as herbicides, insecticides ,

herbicides , mites agent ;

Waste Water : inorganic wastewater ;

| Country: | China |

| Model No: | - |

| FOB Price: | Get Latest Price |

| Place of Origin: | - |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | - |

| Packaging Detail: | - |

| Delivery Time: | - |

| Supplying Ability: | - |

| Payment Type: | - |

| Product Group : | Separation Equipment |