FOB Price

Get Latest Price1 USD /

|1 Minimum Order

Country:

China

Model No:

�2.4X18

FOB Price:

1 USD / Get Latest Price

Place of Origin:

-

Price for Minimum Order:

1

Minimum Order Quantity:

1

Packaging Detail:

-

Delivery Time:

-

Supplying Ability:

-

Payment Type:

-

Product Group :

Contact Person Ms. Seven

No.34 ,Xiaoyi Road, Gongyi, Henan

air dryer for ozone generator

Introduction of WD

Wangda Machinery always firmly follows the tenets of “reputation,

best service, leading technology, quality assurance” and adheres to

“people-oriented, science and technology”. We’re constantly

improving product quality, manufacturing capacity. Produced on the

basis of features of home and abroad manufacturers, our aerated

concrete equipments operate steadily, and have been widely used in

China and exported to Southeast, Asia, Africa, the Middle East and

other countries.

For the sake of users’ approbation, support and expectation, Wangda

Machinery will provide machines with more advanced and better

quality as well as timely and quality

service.

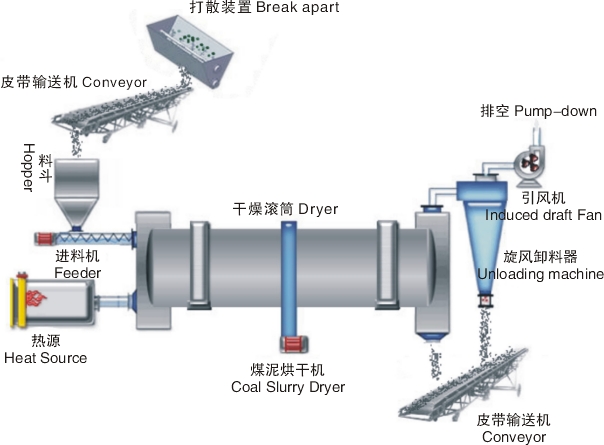

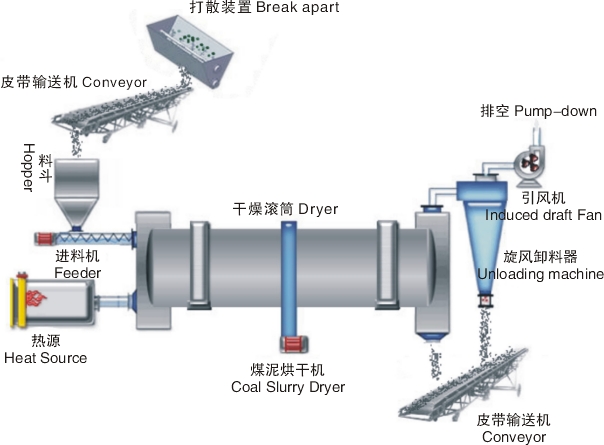

Main Use:

Coal

slurry dryer consists of heat source, beater device, belt loading

machine, feeding machine, rotary roller, belt discharger, draft

fan, discharger, and

switchDue

to the stickiness of the coal slurry, it can be divided into

several working areas. The first is guide area where the wet coal

slurry meets the hyperthermia hot air and its moisture evaporates

fast. As the material is stirred by the shoveling plate of the big

lead angle, the bonding cannot be formed and was sent to another

working area. The second is cleaning area where the wet coal slurry

is raised by the shoveling plate and become the material curtain

type. So as the material drops down, it is likely to be bound with

the rotary drum wall which can be cleaned by the cleaning device

reasonable. In this process, the cleaning device can break the

clotting which increases the heat exchange area thus improves the

drying speed. The third is the slant flitch area where is wet

slurry is in the state of low moisture and loose condition. The

material here won’t bond. After the heat exchange the material meet

the moisture condition demand, and then goes to the last

area-discharging area. There is no shoveling plate here. The

material rolls and slides to the dumping mouth and the whole drying

process are finished.

Technical Parameter:

Specification(m)

φ2.4X*8

Capacity(t/h)

****3

Main

Motor Power(kw) *7/Model

Y**0M*6

MainReducer Model ZL*****-I/SpeedRatio *7.*6

Weight(T) *2

| Country: | China |

| Model No: | �2.4X18 |

| FOB Price: | 1 / Get Latest Price |

| Place of Origin: | - |

| Price for Minimum Order: | 1 |

| Minimum Order Quantity: | 1 |

| Packaging Detail: | - |

| Delivery Time: | - |

| Supplying Ability: | - |

| Payment Type: | - |

| Product Group : | Rotary kiln& cooling machine& dryer |