FOB Price

Get Latest Price10000 USD / Carton ( Negotiable )

|10 Carton Minimum Order

Country:

India

Model No:

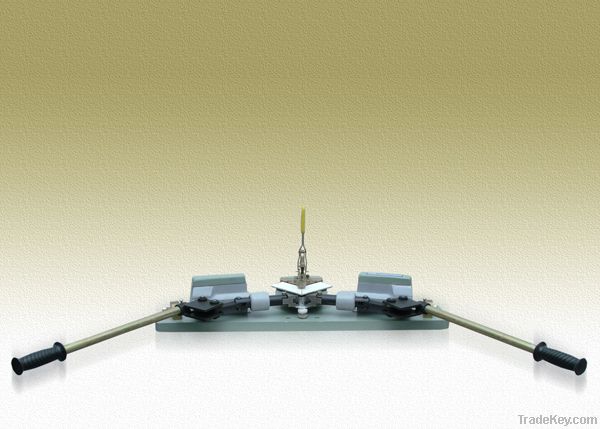

Crimping Machine-3

FOB Price:

10000 USD / Carton ( Negotiable ) Get Latest Price

Place of Origin:

Rajkot

Price for Minimum Order:

10000 per Carton

Minimum Order Quantity:

10 Carton

Packaging Detail:

wooden Box

Delivery Time:

any

Supplying Ability:

100 Carton per Day

Payment Type:

Other, L/C

Product Group :

India

Contact Person Himanshu

Rajkot, Gujarat

please read completely through these insturction before

using the crimper.

your DOUGLAS DE ***0 HAND CRIMPER is supplied factory pre-set for

quic change-over between most aluminium window systems.

PLEASE NOTE :

The crimping bench should be constructed in such a way as to

offer suitable support for the material being crimped, in order

to protect material being crimped from damage, it is advisable to

cover the bench bearers with carpet to similar and keep the

surfaces clear of swarf or objective likely to damage material

surfaces.

SETTING UP

Remove crimper from box, locate on corner of suitable bench,

which must be a robust and stable comstruction. Secure to bench

with four M*0 counters unk bolts or screws. Insert handles into

handle sockets and secure with loking screws which must locate

into dimples provided on handle ends. Remove toggl clamp from

packing and fix to top of anvil block with two M6 x *0 socket cap

screws which are located in the anvil block.

WARNING :

(1) Do not operate the

crimper unless both handles are secured as described above,

failure to comply may result in the handles slipping out of the

sockets and causing a hazard to the operator.

(2) The punch heads are sharp

and must be handled with care.

The DE ***0 hand crimper is designed for two handed operation by

one operator only. It is the operators responsibility to ensure

that the path of the punch heads are unobstructed are operating

the hand lever handles.

TOOLING

CHANGES

ANVIL INSERT

(1) Loosen locking screws (R)

Fig. 1 and lift of insert (Q)

(2) Slide alternative insert

into place, ensure face marked "TOP" is uppermost, locate firmly

on bottom face or pins, ensuring that the rear face of the anvil

insert sits flat against the anvil block.

CRIMP PUNCH HEADS

(1) Remove completely the

retaining screws (J) Fig 1

(2) Pull Punch Heads our of

location slots.

(3) Clean all location

faces.

(4) Select correct punch

heads to match anvil insert, push into location slots, replace

retaining screws (J) and screw down.

TOGGLE CLAMP ADJUSTMENT

(1) Select short mitred

corner from off-cuts of profile to be crimped, insert correct

cleat (s) and corner brance (s) and locate corner on anvil

insert.

(2) Adjust clamp spindle (v)

Fig 1. so that when clamp lever locks ito forward locked position

the test corner is held by the clamp pd, with a pressure

equivalent to a firm finger pressure.

(3) Tighten clamp spindle

lock nuts.

PLEASE NOTE !

If the clamp pressure is set to high, distortion of

profile will occur resulting in poor crimping.

CRIMPING TEST JOINT

Before starting production it is advisable to test toooling

changes as follows :-

(1) Leave small sample corner

piece in position after setting Clamp.

(2) Bring the handles in

towards the centre until Cr5imp Heads touch the profile.

(3) Open box section profiles

the crimp action can be performed by applying equal pressure to

both handles simultaneously until the Link Ars (F) Fig 1. lock

into a straight line with Punch Heads.

(4) When crimping heavy gauge

or closed box section profiles it may be found easier to hold one

Crimp Punch Head firmly against profile for support whilst the

other Head is crimped into it's full depth. Then with a

slight alteration in stance, the first head can be pushed

to it's full depth.

(5) Both crimp Punch heads

should be withdrawn from the profile simultaneously.

PLEASE NOTE !

Under no circumstances should any one Punch Head be used without

firm support of the other one. failure to observe this basic rule

will result in the profile frame moving on the anvil insert, a

poor crimped joint being produced and possible damage to the

Crimper.

SETTING CHECK

The crimper is supplied factory set and has been test crimped

prior to dispatch if for any reason the setting of the crimpter

is in doubt the following procedure should be adopted.

(1) Cut a sample corner of

material to be crimped

(2) Carefully check the cut

and establish that the cut is a true *5, flat and at *0 to both

legs of the section.

(3) Offer the appropriate

setting piece to the anvil insert and check that the setting is

as shown Fig. 2

(4) The punch heads tips

should engage onto the slope of the cleat as shown and should

either just "skim" the setting piece or clear with minimal

clearance.

(5) The punch heads should

ride down the slope until the link arms lock into straight line

with the punch heads. The initial setting for the depth to which

the punch heads should run is approximaterly two thirds of the

full tepth see Fig. 2 The optimum setting is best established by

carrying out test crimps and checking results.

PLEASE NOTE

A Setting Piecd can be made up by fixing with a suitable

adhesive, two packing strips to the back of a cleat that is

to be used in the system. The packing strips must be eqial

in thickness to the wall of the profile to be crimped.

ADJUSTMENTS

Should the crimpel require resetting, both the anvil position and

the depth of bite of the crimp heads are fully adjustable

ANVIL ADJUSTMENT

1) Remove the clamp assembly (U) by removing 2 screws (T), this

will reveal a socket head screw. Slacken this screw.

2) Slacken the four nuts at the extreme rear of the crimper

(S).

3) Using the setting piece as a guide, adjust the anvil towards

or away from the crimp punch heads by turning the nuts. Set

the anvil so that the crimp punch heads ride down the slope of

the setting piece as shown in Fig 2.

ADJUSTMENT OF PUNCH HEADS

Each ram assembly is secured tgo the casting by 2 screws (P),

slaken to allow the punch head assembly to slide in the

casting. By slackenning the lock nut and adjusting screws

(N), the position of the punch heads can be adjusted. Adjustments

should be initially set so that the crimp punch heads run down

the slope on the setting piece to approximately two thrids

depth. The assembles must be locked in this position by

re-rightening the socket screws (P). The final depth

setting is best established by carrying out test crimps and

making minor adjustments until satisfactory results are

obtained.

NOTE

Setting the bite of the punch heads too deeply is to be

discouraged, if set too tight the resulting joits will not

necessarily be tight. "bottoming out"on the cleat is not

necessary when trying to obtain a good quality crimp.

An indication that the cimper is set over tight, is difficulty encountered when withdrawing crimp punch heads from the crimped material

Ensure that all the bolts and nuts are tightened after adjustment have been carried out to maintained settings.

is it important that when the crimper is finally set, the heads should both run equal depths on the test piece.

It is important that the anvil is set so that the crimp punch heads ride down each slope in the same manner, i.e. the anvil must not be set askew relative to the crimp punch heads.

MAINTENANCE

| Country: | India |

| Model No: | Crimping Machine-3 |

| FOB Price: | 10000 / Carton ( Negotiable ) Get Latest Price |

| Place of Origin: | Rajkot |

| Price for Minimum Order: | 10000 per Carton |

| Minimum Order Quantity: | 10 Carton |

| Packaging Detail: | wooden Box |

| Delivery Time: | any |

| Supplying Ability: | 100 Carton per Day |

| Payment Type: | Other, L/C |

| Product Group : | Crimping Machine |