FOB Price

Get Latest Price( Negotiable )

|1 Set Minimum Order

Country:

Algeria

Model No:

YR-220

FOB Price:

( Negotiable ) Get Latest Price

Place of Origin:

-

Price for Minimum Order:

-

Minimum Order Quantity:

1 Set

Packaging Detail:

standard exporting containers

Delivery Time:

about 60days after receipt of deposit

Supplying Ability:

60 Set per Year

Payment Type:

L/C, T/T

Product Group :

Algeria

Contact Person Mr. Brahim

Economical Zone, Ghardaia, Other

Product Description

Full Automatic gypsum powder making production line

Our factory have been specialized in making full automatic gypsum powder making production line for more than 10 years with the up-to-date technology and experienced research and develop team.

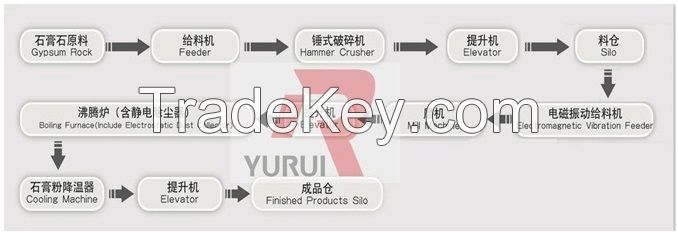

Process introduction of full automatic gypsum powder making production line

The crusher breaks large gypsum rock into small particles of less than 25 mm in diameter, the particles go through storage and transportation equipments into the mill for grinding, use a powder concentrator to select qualified gypsum powder of required fineness and send them into the boiling furnace for calcination. The left unqualified particles will return to the mill for regrinding until meet the requirement. Calcined qualified gypsum powder will be send into the clinker silo for storage or to the workshop for use.

Technological Process of full automatic gypsum powder making production line

The system has high automation degree, convenient control, and can monitor the speed, temperature, humidity and equipment running status at any time, so as to effectively reduce the labor, cost and improve the efficiency. It is the preferred typical equipment in modern building materials industry.

Boiling furnace of full automatic gypsum powder making production line

1. Working principle

The main body of boiling furnace is mainly composed of intensive small diameter radiator coil tubes. Replenish heat conductive oil into the coil tube, and by heat transfer to release heat into the furnace body. Install roots blower at the bottom of the boiling furnace, blow the cold air into the furnace body with air distributor, and blow powder materials inside of the furnace body to make it reach the boiling state. At a certain temperature, the powder materials drained of crystal water after drying become lighter and automatically flow to the discharging entrance.

2. Features of the boiling furnace

♦Simple structure, not easy to be damaged

♦ Compact equipment, small occupation of land

♦ Low energy consumption

♦ Good product quality, ideal phase composition of calcined gypsum, stable physical properties.

Product parameters (GB9776-88) of full automatic gypsum powder making production line

1. Fineness: not less than 100 meshes.

2. Flexural strength (This has a direct relationship with raw materials.): not less than 1.8Mpa; compressive strength: not less than 3.0Mpa.

3. Main phase composition: Semi-hydrated gypsum content: not less than 80%, adjustable Dihydrate gypsum content : less than 5% , adjustable Soluble anhydrous gypsum content: less than 5%, adjustable

4. Initial solidification time: 3 ~ 8 min, adjustable; final solidification time: 6 ~ 15 min, adjustable.

5. Standard consistence: 78 ~ 85%, adjustable

On-site personnel allocation of full automatic gypsum powder making production line

Crushing system 2 persons/day (including forklift driver)

Grinding system 1 person/8 hours (i.e. 3 persons/day)

Calcination system 1 person/8 hours (i.e. 3 persons/day) Heating system 2 persons/8 hours (i.e. 6 persons/day)

Electrical work 2 persons/day

Machine repair 1 person/day

Total: 16 people

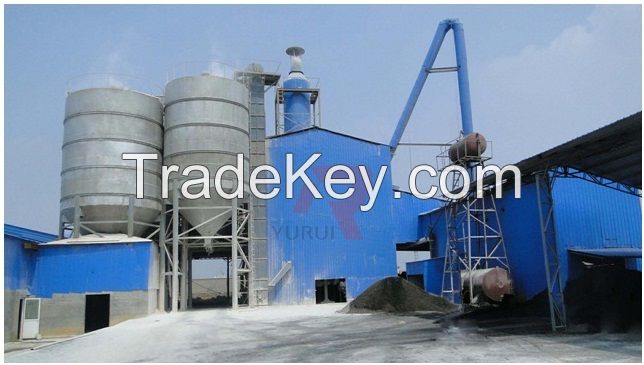

Pictures of full automatic gypsum powder making production line

Products of full automatic gypsum powder making production line

Why choosing us?

Because of professional, professional and professional.

1. Best Price;we have our own factory, who has been specialized in full automatic gypsum powder making production line for more than 10 years, and you are welcome to our factory any time.

2. Superior Quality;quality is the life of all our business, no quality, no living.

3. Best Service;we are the special International Trading Company of our factory, and especially focus on exporting business.

4. Best after-sale service;our engineers will design scale of whole production line and help you with installation and commissioning, and train your workers or employees until they know how to operate all equipment.

Company Information

Shandong Yurui is a manufacturer and trade of construction machinery with well-equipped testing facilities and strong technical force. Our factory have been specialized in making full automatic gypsum powder making production line for more than 10 years.

With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in construction and other industries.

Our Service

1.We offer technical support until the workers know how to operate all equipment of our full automatic gypsum powder making production line.

2.We offer the technology data and relative files of our full automatic gypsum powder making production line. The Operating Instruction will go to the customers with the equipment of full automatic gypsum powder making production line.

3.We provide free answers for all kinds of questions about the full automatic gypsum powder making production line.

4.We provide lifelong guidance of above equipment of full automatic gypsum powder making production line.Visit client in regular times.

Shandong Yurui will be always with you, my dear friend.

| Country: | Algeria |

| Model No: | YR-220 |

| FOB Price: | ( Negotiable ) Get Latest Price |

| Place of Origin: | - |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | 1 Set |

| Packaging Detail: | standard exporting containers |

| Delivery Time: | about 60days after receipt of deposit |

| Supplying Ability: | 60 Set per Year |

| Payment Type: | L/C, T/T |

| Product Group : | Gypsum machinery |