FOB Price

Get Latest Price|

10 Kilogram Minimum Order

Country:

China

Model No:

-

FOB Price:

Place of Origin:

-

Price for Minimum Order:

-

Minimum Order Quantity:

10 Kilogram

Packaging Detail:

-

Delivery Time:

-

Supplying Ability:

-

Payment Type:

T/T, D/P, PayPal

Product Group :

-

Contact Person Mr. Iurii

flat/rm A12/F ZJ300, 300 Lockhart Road, Wan Chai, Hong Kong

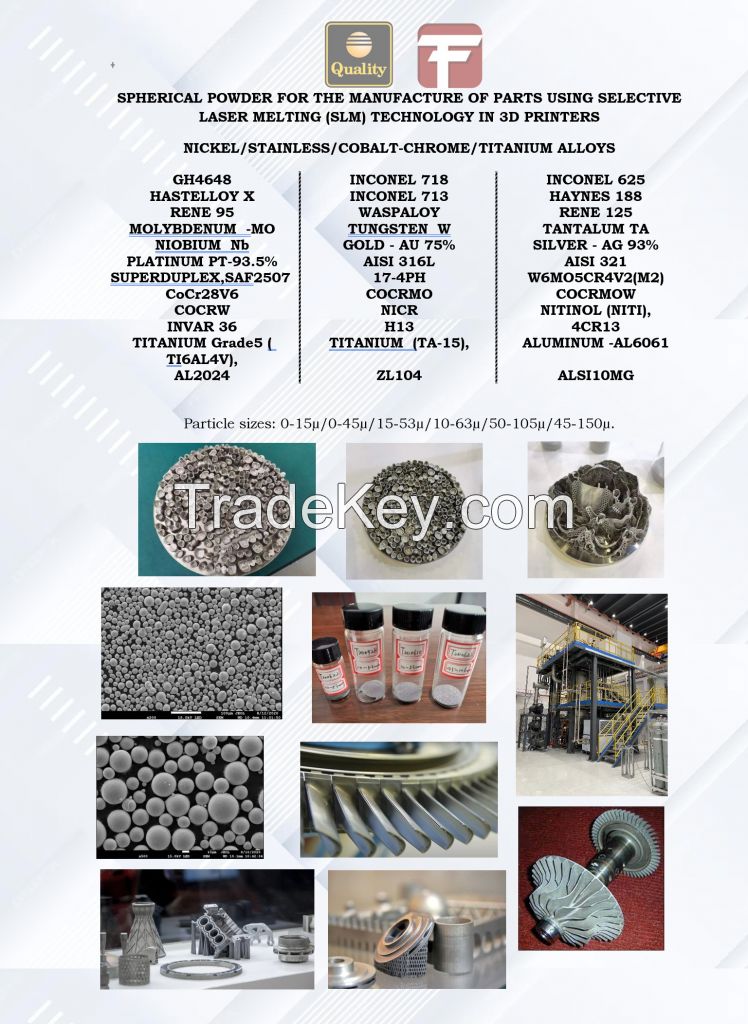

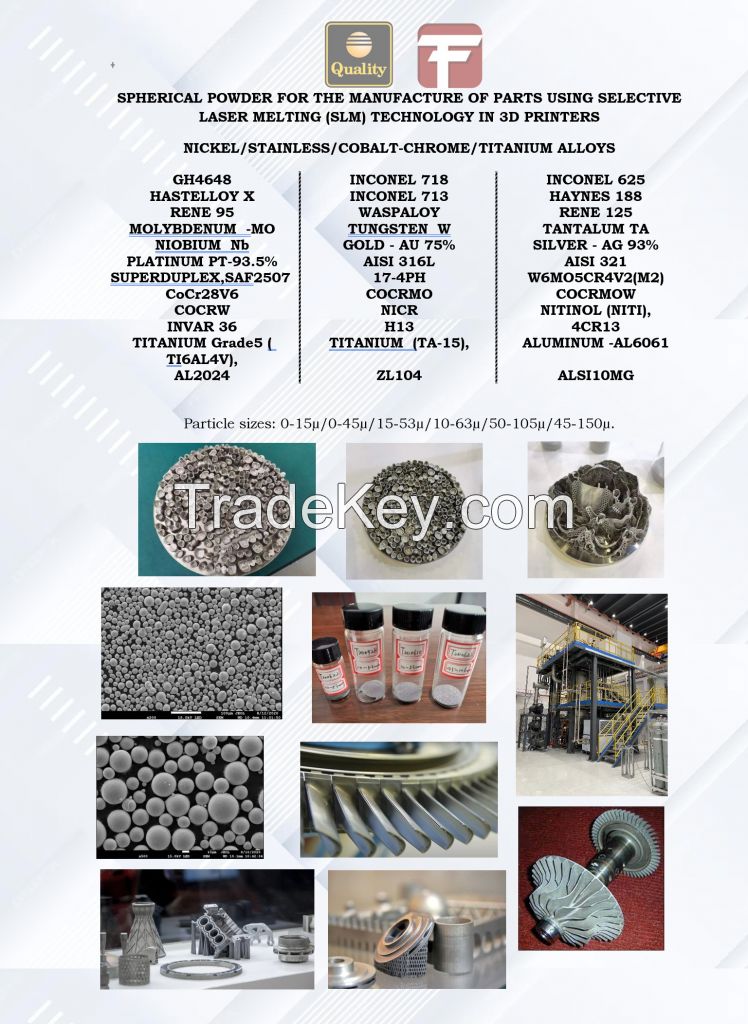

NICKEL/STAINLESS/COBALT-CHROMIUM/TITANIUM ALLOYS

Particle sizes:

***5µ/***5µ/****3µ/****3µ/*****5µ/*****0µ.

Selective Laser Melting (SLM) is an advanced additive manufacturing

technology that plays a crucial role in the modern industrial

revolution. In SLM, 3D printers directly process metal powder to

rapidly create necessary parts. This technology enables

unparalleled manufacturing speeds, allowing for the production of

durable and efficient components with excellent metal structure

performance and thermal properties.

Heres how SLM works:

Metal Powder Layering: A squeegee spreads a thin layer of metal

powder onto a build platform.

Laser Scanning and Melting: A high-power laser scans the

cross-section of the part, selectively melting the powder in

specific areas. The melted powder solidifies to form the desired

shape.

Layer-by-Layer Building: The build platform drops down to the next

layer height, and the process repeats, adding another layer of

powder material*2.

Advantages of SLM technology include:

No Molds Required: Unlike traditional methods, SLM doesnt need

molds, reducing production time and costs.

Complex Geometries: SLM can create intricate structures, such as

cavities and three-dimensional grids.

Improved Material Utilization: Strong comprehensive functions lead

to reduced assembly time and better material utilization.

Comparable Mechanical Performance: SLM-produced parts exhibit

mechanical load performance similar to traditional methods like

forging1.

In summary, SLM technology revolutionizes manufacturing by enabling

rapid production of high-quality metal parts without expensive

equipment or molds. Researchers continue to explore process

parameters, materials, and address challenges faced by SLM1.

| Country: | China |

| Model No: | - |

| FOB Price: | Get Latest Price |

| Place of Origin: | - |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | 10 Kilogram |

| Packaging Detail: | - |

| Delivery Time: | - |

| Supplying Ability: | - |

| Payment Type: | T/T, D/P, PayPal |

| Product Group : | - |