Product Description

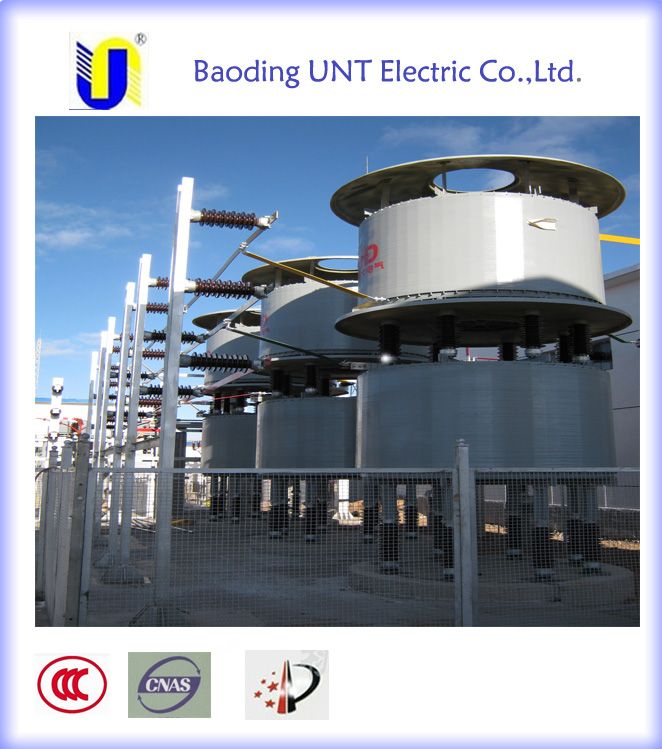

Overview:

Applying the rated voltage 6KV-35KV AC power system, TCR-type SVC

can dynamically and continuously adjust reactive power, absorb

harmonic, and reduce voltage fluctuations and voltage flicker. The

device improves power factor, decreases losses, and improves the

transmission ability of power network and users’ voltage quality,

which brings enormous economic and social benefits for

users.

Working

principle

TCR-type SVC is consisted of thyristor controlled reactor (TCR) and

fixed capacitor (FC). The capacitor supplies fixed capacitive

reactive (Qc) in the branch of TCR consisting of phase controlled

reactors and thyristor valve group. Under the function of control

signal, and it is equal to a variable inductance. By changing the

reactor current. it changes the inductive reactor power (Qtcr) of

the TCR branch output, and the inductive reactor power and the

capacitive reactor power cancel each other. When the system is

reactive power (Qn=Qv-Qc+Qtcr=0), the power network factor is

constant to protect the voltage stability.

Product

Selection

SVC selection

UNT-TCR-SVC-1/2-3

UNT------Baoding UNT Electric Co., Ltd.

TCR------Thyristor controlled reactor(TCR)

SVC------SVC product code

1---------Rated capacitance of SVC, MVar

2---------Rated voltage of SVC, 6-35KV

3---------Total installation capacitance of filter capacitor

bank, unit: Mvar

Thyristor valve block selection:

UNT-1-2-3

UNT--------Baoding UNT Electric Co., Ltd.

1---------TCRF indicates TCR thyristor valve block and TSCF TSC

thyristor valve block

2---------Voltage grade of thyristor valve block

3---------S indicates water cooling, R thermal pipe cooling and X

sectional bar cooling

Structure

Digital control system

Structure: Standard Cabinet Structure

Functions: The controlling cabinet is used for real-timely

calculating the reactive power of the power network, controlling

the size of the thyristor firing angle, and controlling the size

of the compensation amount of reactive power. The protection

cabinet is used for the protection of the capacitor bank and

phased reactor.

Thyristor Valve Group

Thyristor Valve Group receives the signal of the controlling

system, changes the size of the thyristor firing angle, and

produces the corresponding reactive compensation current.

High-voltage thyristor can be domestic manufactured or imported

as per the request of users. High-frequency constant-current loop

is self-created energy, with trigger monitoring, BOD protection

and other functions.

Compensation phase-controlled reactor

Structure: the reactor is air-core dry-type reactor, double

wilding, natural cooling

Functions: The current passing through thyristor passes the

compensating reactor, the device produces the inductive reactor

for the system, the device can balance the capacitor reactor of

the system and stabilize the bus voltage.

High Harmonic Filtering Installation

The three parts including reactor, electrical capacitor and

resistors (only for high pass channel) consists a filtering

channel. According to the system requirements, the device can

make up several filtering channels for filtering the

corresponding high harmonic wave.

Structure: the reactor is air-core dry-type reactor and natural

cooling. Electrical capacitor is shelf and natural cooling.

Function: The device can eliminate the high harmonic wave passing

though system, provides the capacitor reactive power to system,

and increases power factor.

Main Technical

Indexes

|

Working conditions

|

|

Single at collection terminals

|

PT rated voltage:AC 100V

CT rated current:AC 5A

|

|

Control power supply

|

DC220V/10A and AC220V/10A

|

|

Environment requirement

|

Installation environment:

Control cabinet,protective cabinet and thyristor valve

blocks are of indoor installation other equipment may be

installed indoor or outdoor.

Ambient temperature:-25℃-+45℃

Relative humidity:5%-95% (at 25℃)

Altitude: below 2,000m(over 2,000m special requirements are

needed for ordering)

Contaminant: Level IV

Locations without fine metal particles, conductive dusts,

corrosive gas in air and violent vibration

|

|

Items

|

Technical index

|

|

System voltage level(kv)

|

6-35

|

|

TCR rated capacitance(MVar)

|

1-150

|

|

Control system response time(ms)

|

≤20

|

|

System response period(ms)

|

≤30

|

|

Firing angle scope

|

100°-165°

|

|

Thyristor valve block structure

|

Open combined modular

|

|

Cooling method of thyristor valves

|

Thermal pipe cooling or full-closed deionized water cooling

|

|

Firing method

|

opto-electric firing

|

|

Redundant thyristor(pc)

|

6-10kv:1

27.5-35kv:2

|

|

Control system

|

DSP full-digital control system

|

|

Regulation method

|

Three-phase/phase independent regulation

|

|

Operation mode

|

Manual/ automatic

|

|

Control mode

|

System based:

1.Quick admittance control

2. Constant voltage control

Load based:

1.Voltage priority, power factorcontrol

2.Constant reactive power control

|

|

TCR main circuit structure

|

Delta connection

|

|

FC main circuit structure

|

Y connection

|

|

Branch filters

|

Branch filter configured according to system requirements

Filtering harmonic orders(order 2-order 13)

|

|

Communication

|

|

Communication interface

|

RS-485 or ethernet

|

|

Communication Protocol

|

Modbus RTU or 104

|

|

Operation interface

|

|

User-friendly man-machine interface

|

10-inch colored touch screen display

|

|

Selectable Display items on touching screenmain

|

Interface:Running status and running parameters operation

interface, parameter setting interface, running record

interface and fault alarm interface

|

Features

1.The sampling control system adopts the multiprocessor with

digital parallel processing technology, it has high control

precision and fast dynamic response to insure the step response

time below 20ms.

2.The device achieves the multiple sets of TCR coordinated control

at the same segment bus to avoid oscillation and improve the system

stability.

3.The device controls algorithm of different users (system and

load) avoids the resonance of the system and improves the overall

reliability of the system.

4.With the independent research and development, the thyristor

valve group adopts the modular design to supply integrated

structure for the various capacitors’ device.

5.The cooling mode of the thyristor valve group is heating pipes

cooling and fully closed deionized water cooling.

6.We own the patents of thyristor dynamic security monitoring and

protection technology. The device guarantees more reliable

operation of the high power thyristor valve bank in

series.

7.The power of the thyristor trigger unit adopts patented

technology of the high-frequency constant current source power

supply and achieves the anti-jamming capability and solves the high

and low voltage insulation isolation problem.

8.With flexible controlling mode, the users can set it by

themselves according to the site requirement. The device can be

adjusted by three-phase and spilt phase.

9.The device can control coordinately the high-voltage and the low

voltage dynamic reactive power compensation to improve the overall

operating efficiency.

10.With independent intellectual property rights, the wind farm

reactive power flow controller can achieve the optimized control of

the wind farm reactive power flow.

11.The self-researched capacitor branch protection unit can fastly

and accurately achieve all the protection functions for the

capacitor bank.

12.The device makes program design based on the monitored harmonic

wave data in site and simulates strictly.

Applications

Wind field, electrical arc furnace, Metallurgy, Electrified

railway, Hoister, Coal, Steel plant, Electric power substation,

Chemical, oil, Mine, Building

| Country: |

China |

| Model No: |

-

|

| FOB Price: |

5000 ~ 50000 / Set ( Negotiable ) (Negotiable)

Get Latest Price

|

| Place of Origin: |

- |

| Price for Minimum Order: |

5000 per Set |

| Minimum Order Quantity: |

1 Set |

| Packaging Detail: |

wooden or as customers' requirements |

| Delivery Time: |

more or less 20 days |

| Supplying Ability: |

15 Set per Month |

| Payment Type: |

T/T, L/C, Western Union, Money Gram, PayPal |

| Product Group : |

reactive power compensation

|