Vacuum quenching refers to the smooth quenching of parts. The

quenching and cooling of parts are carried out in the vacuum

furnace, and the quenching medium is mainly gas (such as

inert gas), water and vacuum quenching oil. Vacuum quenching

has been widely used in the quenching of various steels,

alloy tool steels, high-speed steels and stainless steels, as

well as the solution treatment of various aging alloys and

hard magnetic alloys.

There are two kinds of quenching in vacuum: gas quenching and

liquid quenching. Gas quenching is when the workpiece is

heated in a vacuum and then cooled by high-purity neutral gas

(such as nitrogen) in the cooling chamber. High-speed steel

and high carbon and high chromium steel are suitable for gas

quenching. Liquid quenching is to heat the workpiece in the

heating chamber, move it to the cooling chamber, fill it with

high-purity nitrogen, and immediately send it to the

quenching oil tank for rapid cooling. If high surface quality

is needed, tempering and precipitation hardening after vacuum

quenching and solution heat treatment should still be carried

out in a vacuum furnace.

1. Especially suitable for carburizing steel, stainless steel

and air-cooling steel, more suitable for small holes, and

blind holes.

2. Stainless steel can achieve excellent effects without

removing passive film.

3. No black structure, reduce fatigue sources, greatly

improve the life of parts.

4. It can be carburized at medium temperature and high

temperature and high speed with high efficiency.

5. Precise vacuum low-pressure carburizing process, stable

operation, good reproducibility.

6. The one- intelligent control system can accurately

control the surface carbon content, and the carburized layer

depth is uniform.

Vacuum Gas Quenching Medium:

The cooling rate of vacuum air quenching is related to the

type of gas, gas pressure, flow rate, furnace structure and

loading condition. Available gases are Ar, He, H, and N,.

Assuming that the heat transfer rate of air under the same

conditions is 1, then Ar is 0.*0, He is 6, H is 7, and N2 is

0.*9.

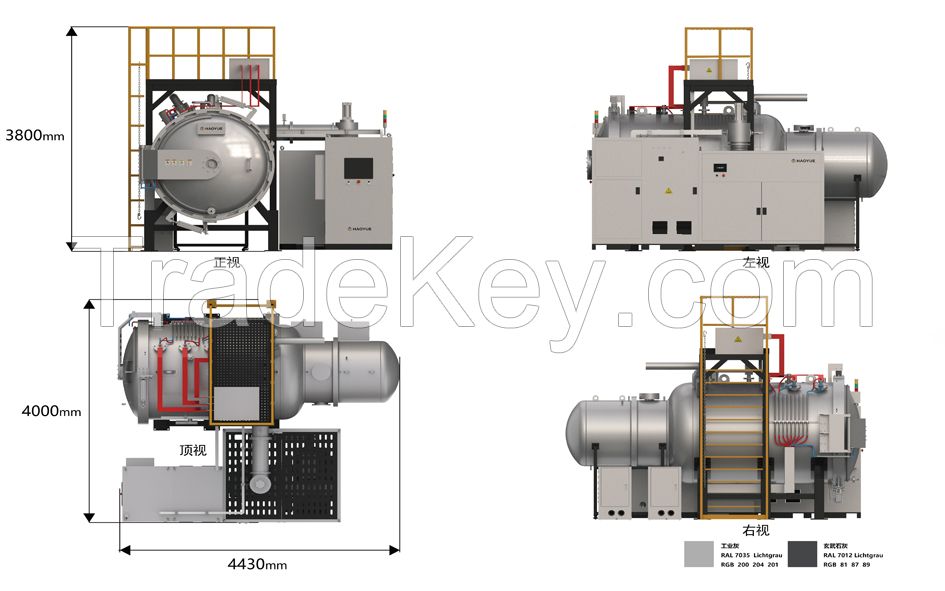

Specifications

A Vacuum Gas Quenching Furnace is applied for quenching

high-speed tool steel, measuring vacuum hardening and cutting

steel, tool steel and other alloy steel, with a convection

heating function, which can achieve the process of step

hardening, isothermal quenching, but also tempering,

annealing and other heat treatment process. Ultimate

pressure: cooling gas,6Bar or *0Bar. The control system was

controlled by PLC, temperature was controlled by an

intelligent temp controller, accurate control, and high

automation. Users can choose auto or manual undisturbed

switching to operate it, this furnace has abnormal conditions

and alarming function, easy to operate. The environmental

protection performance of vacuum furnaces has been improved,

with maintenance cost saving, energy cost savings.

Numbering Model Working Zone size(mm) Capacity(kg) Heating

material Cooling Gas HeatingPower

(KW) Max temperature (℃) Temperature

uniformity(℃) Limit vacuum degree (PA) Air

cooling pressure (bar)

VHG***6 VHGgr**0/*0/******0 **0x**0x**0 **0 Graphite N2/Ar *0

***0 ±5 6x***1Pa *0

VHG***9 VHGgr**0/*0/******0 **0x**0x**0 **0 Graphite N2/Ar

**0 ***0 ±5 6x***1Pa *0

VHG****2 VHGgr**0/*0/*******0 **0x**0x***0 ***0 Graphite

N2/Ar **0 ***0 ±5 6x***1Pa *0

Remark: The working zone of equipment could be customized

based on the customer's production.

The Vacuum Gas Quenching Furnace produced by Haoyue is a

high-quality product for the vacuum air quenching process of

the tool and mold. Good temperature control accuracy and

uniformity ensure the effective progress of the vacuum air

quenching process. Haoyue specializes in the manufacture of

vacuum furnaces, has more than ten years of relevant

experience, and has a good reputation in the field of vacuum

furnace manufacturing. The product line includes vacuum

annealing furnaces, vacuum oil quenching furnaces, vacuum

brazing furnaces, etc., widely sold in developed and

developing countries.