FOB Price

Get Latest Price1950 ~ 3000 USD / Piece

|2 Piece Minimum Order

Country:

China

Model No:

2SK-6B

FOB Price:

1950 ~ 3000 USD / Piece Get Latest Price

Place of Origin:

Taizhou,Zhejiang

Price for Minimum Order:

1950 per Piece

Minimum Order Quantity:

2 Piece

Packaging Detail:

Neutral Wood

Delivery Time:

7-20 Days

Supplying Ability:

500 Piece per Month

Payment Type:

L/C, T/T, D/P, Western Union, PayPal

Product Group :

-

Contact Person Meera

Wenzhou, Zhejiang

DESCRIPTION

2SK Series Two-Stage Liquid Ring Vacuum

Pumps can work well like two sets of SK series water ring

vacuum pump. Due to SK series vacuum pumps only reach the maximum

vacuum of***0mmHg, to meet the high vacuum and the large pumping

speed under high vacuum, China developed the 2SK series water

ring vacuum pump in *0s in the *0th

century.

ADVANTAGE

1. Compared with SK water vacuum pump ,It

gets high vacuum and pumping speed etc..

2. Simple structure and easy

maintenance.

3. The mostly working medium is water and

low maintenance costs.

4.The pump is widely use in many areas and

suction water vapor,flammable, explosive and various gases

contain a small amount of dust and liquid.

5. The pump can works in the harsh

condition

FEATURES

1. Series SK,2SK Water Ring Vacuum Pumps

can be used to exhaust ordinary gases as well as condensable

gases(such as water vapor). Because they have the features of

isothermal compression, they can exhaust flammable and explosive

gases. When the pump made up of anti-corrosion material is

selected, it can be used for exhausting corrosive gases

too.

2. Series 2YK Liquid Ring Vacuum Pumps

have the features of higher vacuum and better applicability. The

different types of gases can be pumped with the selected suitable

working media. Therefore, they can be applied in wider

range.

3. The pumps run smoothly with low noise

and consumption. The energy-saving is *0 percent comparing with

the Water Jet and the Water Vapor Jet Pumps.

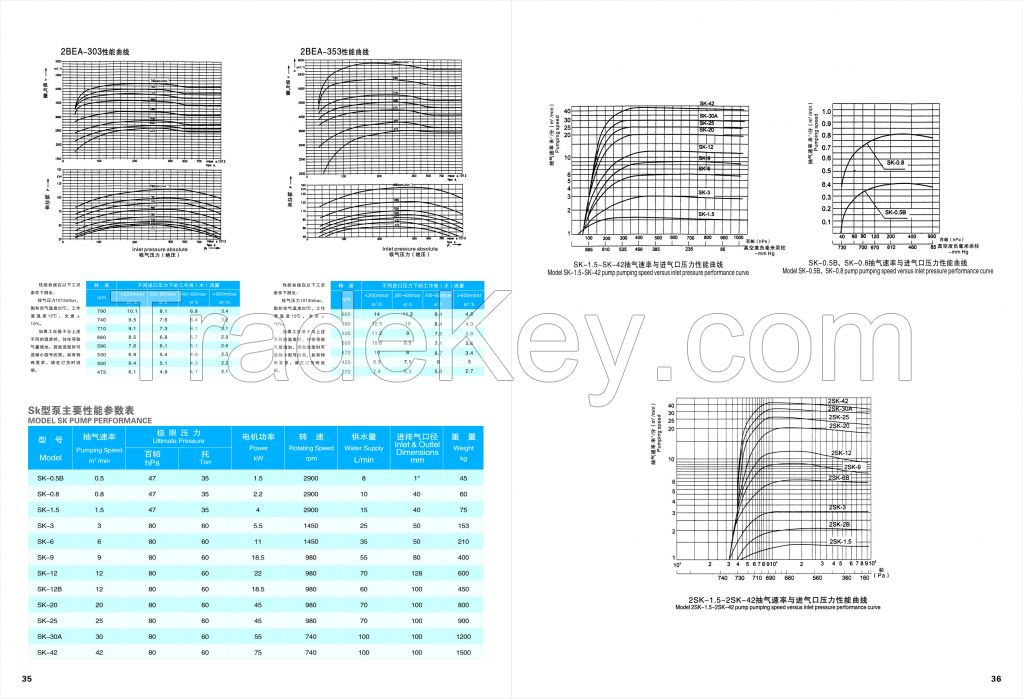

PARAMETER

| Model |

Displacement ( m 3 /min ) |

Ultimate Pressure(hpa) |

Motor Power (kW) |

Rotating Speed ( rpm ) |

Water Supply ( L/min ) |

Inlet&Outlet Dimensions ( mm ) | Weight ( kg ) |

| SK*0.5B | 0.5 | *7 | 1.5 | ***0 | 8 | *5 | *5 |

| SK*0.8 | 0.8 | *7 | 2.2 | ***0 | *0 | *0 | *0 |

| SK*1.5 | 1.5 | *7 | 4 | ***0 | *5 | *0 | *5 |

| SK*3 | 3 | *0 | 5.5 | ***0 | *5 | *0 | **3 |

| SK*6 | 6 | *0 | *1 | ***0 | *5 | *0 | **0 |

| SK**2 | *2 | *0 | *2 | **0 | *0 | **0 | **0 |

| SK**2B | *2 | *0 | *8.5 | **0 | *0 | **0 | **0 |

| SK**5 | *5 | *0 | *5 | **0 | *0 | **0 | **0 |

| SK**0 | *0 | *0 | *5 | **0 | *5 | **0 | ***0 |

| SK**2 | *2 | *0 | *5 | **0 | **0 | **0 | ***0 |

| 2SK*2B | 2 | *0 | 5.5 | ***0 | *0 | *0 | **5 |

| 2YK*2B | 2 | 6.6 | 5.5 | ***0 | *0 | *0 | **5 |

| 2SK*3 | 3 | *0 | 7.5 | ***0 | *5 | *0 | **0 |

| 2YK*3 | 3 | 6.6 | 7.5 | ***0 | *5 | *0 | **0 |

| 2SK*6B | 6 | *3 | *1 | ***0 | *0 | *0 | **0 |

| 2YK*6B | 6 | 6.6 | *1 | ***0 | *0 | *0 | **0 |

| 2SK**2 | *2 | *3 | *2 | **0 | *0 | *0 | **0 |

| 2YK**2 | *2 | 6.6 | *2 | **0 | *0 | *0 | **0 |

| 2SK**5 | *5 | *3 | *5 *5 | **0 | *****0 | **0 | **6 |

| 2YK**5 | *5 | 6.6 | *5 *5 | **0 | *****0 | **0 | **6 |

APPLICATIONS

It can be applied to the vacuum drying, vacuum degassing, vacuum concentration, vacuum evaporation, vacuum impregnation process in chemical, pharmaceutical, metallurgy, food, medicine, textile, papermaking, electrical industry ( electronic industrial field) and so on. It can compose a vacuum system together with Roots Vacuum Pump and atmospheric Jet pump to achieve high vacuum, high efficiency, low power consumption.

Regular Selection for Water/Liquid Ring

Vacuum Pump

1,Based on the vacuum value

(1)If the pump is operated for long time with the inlet pressure range between1.3×**4~1×**5Pa (between **0 and **0 Torr), please choose series SK Water Ring Vacuum Pump.

(2)If the pump is operated for long time with the inlet pressure range between5×**3~1.3×**4Pa(between*0 and **0 Torr), please choose series 2SK Water Ring Vacuum Pump.

(3)If the pump is operated for long time with the inlet pressure range between1×**3~1.3×**4Pa(between8 and **0 Torr), please choose series 2YK Liquid Ring Vacuum Pump.

2,Working Media

There are four principles to choose working media(i.e.ring liquids);

(1) Lower saturated steam pressure

(2) Lower viscosity

(3) Stable physical & chemical features; no chemical reaction with the pumped gas;no corrosion to the pump; no pollution to the environment.

(4) Economy

If the water is

selected as the working medium, the best temperature of supply

water should be lower than or equal to *5 °C; the highest one

should not be higher than *0°C. While the transformer oil or

other low viscosity and saturated vapor pressure industrial oils

are as the working media, the general supply temperature should

not higher than *0°C and the working media temperature inside the

pump chamber should not be higher than *0C, when the liquid with

lower boiling point is selected as the working media under some

special circumstances, the cooling unit must be equipped to cool

down the working media in order to ensure that the max

temperature is *0ºC**0ºC, lower than the boiling point. For the

closed circulated system of working media, the liquid storage

unit and cooler must be equipped, and the gas-liquid separator

must be installed at outlet. The mechanical seal should be used

for dynamic seal of the shaft.

3,Choose the dynamic seal of the shaft:

Choose the packing seal in general occasion; choose the mechanical seal when the pump is used in no leak occasion.

4,Choose the material of the part that the gas passed:

(1) For the non anti-corrosion pump, the

shaft is made of *5#steel or *0Cr, other parts are made of cast

Iron or brass;

(2) For the anti-corrosion pump,the parts

that the gas passed, should be made of stainless steel **4 and

**6, or other material suitable for the respectively corrosive

gas, or the parts should be put with anti-corrosion

coating.

5, The motor should be selected based on pumping pressure.

If the pump is used for vacuuming while

transferring gas, the pressure of pump outlet exceeds the

standard atmosphere pressure.

When the outlet pressure exceeds 0.*5MPa,

the special double-stages liquid ring compressor should be chosen

and not the vacuum pump refitted. Tthe power of the equipped

motor should be increased obviously. And the special gas-liquid

separator and auto-drain unit should be equipped

too.

When the outlet pressure is below 0.*5MPa,

it can use the vacuum pump refitted as compressor. The power of

the equipped motor should be increased

properly.

6,Composition methods of the water ring vacuum pump system

The opening circulation system should be used if the working liquid in the outlet need not be circulated or partially circulated.

The closed circulation system should be used if the working liquid in the outlet must be circulated

DVE SERVICE

Sea

Port:

Ningbo/Shanghai, China

Standard:

CE Mark, Spare Parts Of High Level

Delivery:

Normally according to our factory production schedule,

but we can follow your first order

time

Warranty:

If pump appear quality problems, free replacements of spare parts

will be offered within one year

WE CAN PROVIDE

YOU

1. On-time Delivery, with More

Choice

2. Perfect Technical

Support

3. Customized Vacuum Solutions and

Service

4. Samples Available

5. Long Quality

Guarantee

6. Fast Response to Customers' Feedback

in *2 hours

DEVELOPMENT VACUUM EQUIPMENT CO.,

LTD

ADD:DONGGANG INDZONE, TAIZHOU, ZHEJIANG,

CHINA PC: *****6

TEL:***************8

FAX:***************9

| Country: | China |

| Model No: | 2SK-6B |

| FOB Price: | 1950 ~ 3000 / Piece Get Latest Price |

| Place of Origin: | Taizhou,Zhejiang |

| Price for Minimum Order: | 1950 per Piece |

| Minimum Order Quantity: | 2 Piece |

| Packaging Detail: | Neutral Wood |

| Delivery Time: | 7-20 Days |

| Supplying Ability: | 500 Piece per Month |

| Payment Type: | L/C, T/T, D/P, Western Union, PayPal |

| Product Group : | - |