FOB Price

Get Latest Price5000 ~ 50000 USD / Set ( Negotiable )

|1 Set Minimum Order

Country:

China

Model No:

SL-1000

FOB Price:

5000 ~ 50000 USD / Set ( Negotiable ) Get Latest Price

Place of Origin:

China

Price for Minimum Order:

5000 per Set

Minimum Order Quantity:

1 Set

Packaging Detail:

wooden box/full container

Delivery Time:

15-20 working days

Supplying Ability:

50 Set per Month

Payment Type:

T/T, L/C, D/A, D/P

Product Group :

Contact Person Apple

Carson City, Nevada

Waste Plastic Recycling HDPE PET PE PP Bottle Plastic

Crusher Crushing Machine

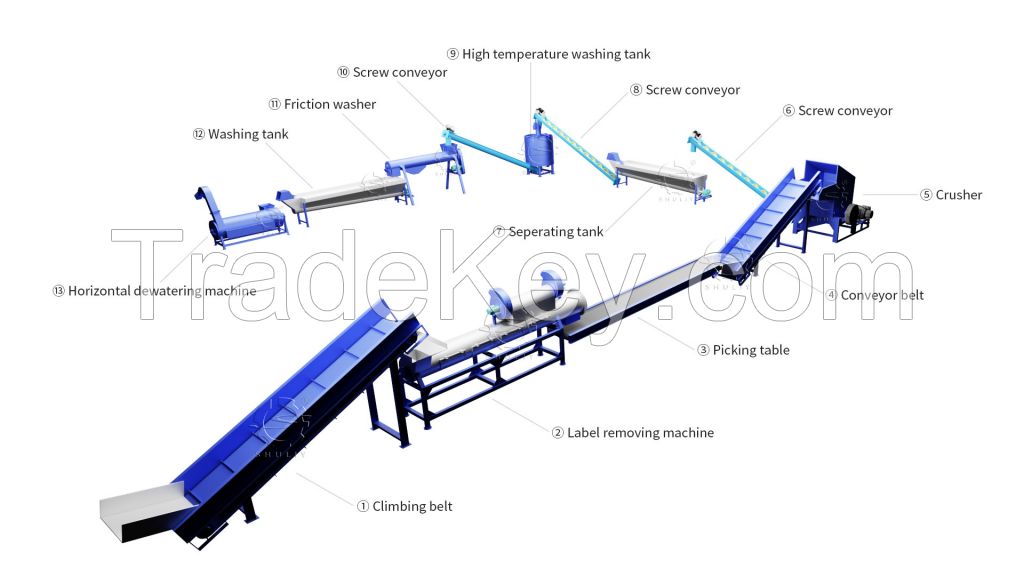

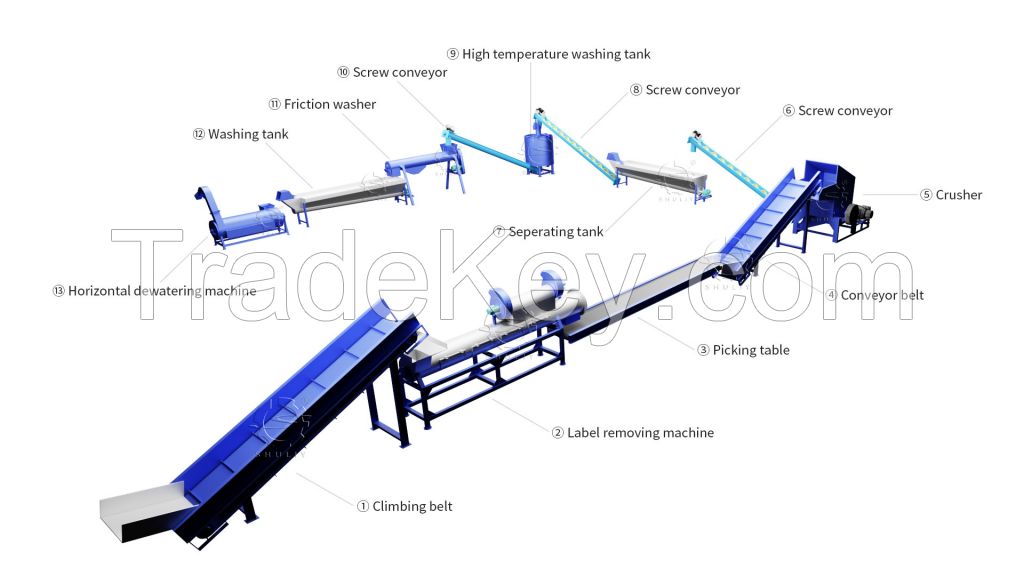

The raw material

for our PET recycling machine is PET bottles, also called them cold

water bottles.

The main

function of PET recycling machine is to crush and clean the PET

bottles.

In the process

of crushing and cleaning, the raw materials of the bottle cap and

the bottle body are different, so the caps will be

separated in the process, leaving only the bottle body. And the

final product obtained is clean PET flakes.

Production

Process:

1. Climbing

Conveyor:Convey the bottle to label removing

machine.

2. Label

Removing Machine: Remove the label from the

bottle.

3. Sorting

Conveyor:Transfer the no label bottle to another climbing

conveyor,At the same time ,select again not

fully removing label bottles and

different colors bottles.

4. Climbing

Conveyor:Convey the bottle to bottles crushing

machine.

5. PET Bottle

Crusher Machine:Crush the bottles into small

chips.

6. Screw

Conveyor:Convey the plastic chips into PET ,PP washing and

separating machine.

7. PET, PP,PE

washing and separating machine:washing and Separate PET chips and

PE bottle cap.

8. Screw

Conveyor:Convey washed PET chips into high temperature washing

barrel.

9. High

Temperature Washing Barrel:Wash PET chips with hot water and

cleaning agent.

10. Screw

Conveyor:Convey washed PET chips into rubbing washing

machine.

11. Rubbing

Washing Machine:With water recycling , clean the PET bottle

enough ,remove cleaning agent and other

impurity.

12. PET,PP,PP

washing and separating machine:Separate PET chips and PE ,PP bottle

cap completely .

13. PET Chips

Dewatering Machine:Dewatering for PET chips

Capacity:

PET recycling

machine smalleast capacity is 500kg/hour.

We also have

1000kg/hour,1500kg/hour,2000kg/hour and so on.

We can customize

according to your demands.

Application:

1.PET flakes can

make packing belt.

2.PET flakes can

add some other material to do something,such as add some lime to

make tiles.

3.PET flakes can

make new plastic products,these products can used for industry.

| Country: | China |

| Model No: | SL-1000 |

| FOB Price: | 5000 ~ 50000 / Set ( Negotiable ) Get Latest Price |

| Place of Origin: | China |

| Price for Minimum Order: | 5000 per Set |

| Minimum Order Quantity: | 1 Set |

| Packaging Detail: | wooden box/full container |

| Delivery Time: | 15-20 working days |

| Supplying Ability: | 50 Set per Month |

| Payment Type: | T/T, L/C, D/A, D/P |

| Product Group : | Plastic Recycling Machine |