FOB Price

Get Latest Price|

- Minimum Order

Country:

USA

Model No:

-

FOB Price:

Place of Origin:

-

Price for Minimum Order:

-

Minimum Order Quantity:

-

Packaging Detail:

-

Delivery Time:

-

Supplying Ability:

-

Payment Type:

-

Product Group :

-

Contact Person Ms. Rhonda

P.O. Box 1200, Dripping Springs, Tx. 78620, Dripping Springs, Texas

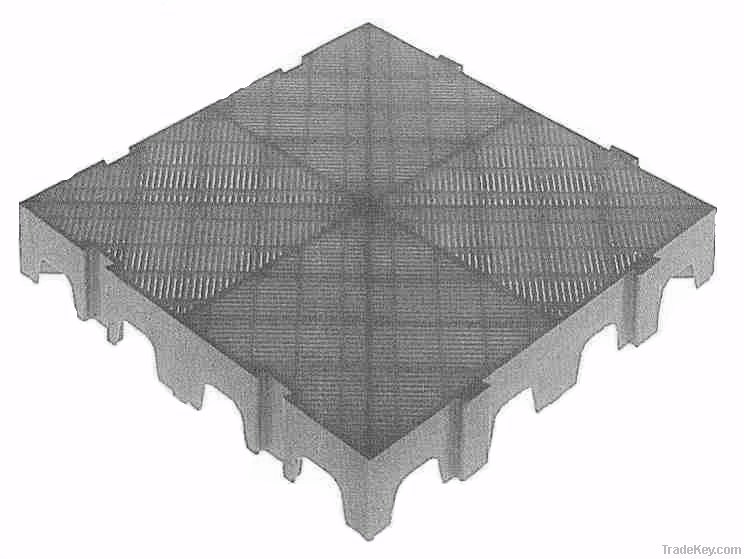

The Wedgewater� Filter Bed

System�is

the result of intensive research, rigorous field testing, and years

of experience in screen and filter design and manufacture. It

offers highly cost-effective sludge dewatering, with significant

advantages over both slow, space-consuming sand drying beds and

costly, energy-intensive mechanical dewatering

units.

This unique

system�is composed of interlocking *2� x *2�

high-density polyureth-ane filter modules. Practically

indestructible, these panels shrug off the effects of sun and

environment, are corrosion and abrasion resistant, nonconductive

and virtually maintenance free.

Each module features

�a special non-clogging orifice design, *2%

open area, and�built-in underdrain which insures continuous

dewatering. Integral, molded-in structural elements allow the

panels to easily support small front-end loaders for sludge cake

removal. The interlocking panel modules make setup and panel

replacement a snap � without tools!

�All Types

�of sanitary sewage and water treatment

sludges are efficiently dewatered�by Wedgewater� Filter Beds. The

system also effectively dewaters most biological and chemical

industrial sludges. It is suited to both indoor and outdoor

applications. Unaffected by wide variations in concentration, the

system can dewater a 1% aerobically digested sludge one day,

followed by a 5% primary sludge the next. Even the most dilute

sludges can be economically concentrated.

The filtrate extracted

�by the process is of a high quality, usually

less than *0 ppm�suspended solids, with low BOD and COD levels. The

filter panel design maintains sludge porosity, prevents media

blinding and maintains filtrate drainage at the optimal rate. The

high capture rate and unusually clear filtrate allow many plants to

discharge the effluent directly into tertiary

processes.

After

dewatering,�the sludge is left suspended on a dry media.

The circulation of�air both above and below the layer of sludge

speeds drying. The sludge cake can then be easily removed with

mechanical loaders.

Save time and money

�in your

dewatering operations � contact your Gravity

Flow�Systems Southwest, Inc. representative for a

complete proposal on implementing the cost-effective Wedgewater�

Filter Bed System.

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

| Country: | USA |

| Model No: | - |

| FOB Price: | Get Latest Price |

| Place of Origin: | - |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | - |

| Packaging Detail: | - |

| Delivery Time: | - |

| Supplying Ability: | - |

| Payment Type: | - |

| Product Group : | - |