FOB Price

Get Latest Price100000 ~ 100001 USD / Set

|4 Set Minimum Order

Country:

China

Model No:

150000cubic meter annual

FOB Price:

100000 ~ 100001 USD / Set Get Latest Price

Place of Origin:

china

Price for Minimum Order:

100000 per Set

Minimum Order Quantity:

4 Set

Packaging Detail:

wood box

Delivery Time:

20 days

Supplying Ability:

4 Set per Week

Payment Type:

T/T, L/C, D/A, D/P

Product Group :

Contact Person mill2-jasminejuan

No.33 Shenxia Road, Malu Industrial Park, Jiading District, Shanghai

AAC Block forming process

1 The Preparing of The Raw Materials

A. The Preparing of The Slurry

B. The Preparing of The Lime

C. Cement

D. Stone Powder

E. Waste material

2. Batching, Mixing, Pouring

3. Resting and Pre-curing

4. Demoulding, Cutting, Grouping

5. Curing, Finished Product Leaving Autoclave

6. The Reclaim System of Waste Water & Slurry

aerated autoclaved concrete plant, AAC block,aac production line,aac plant,AAC brick,autoclave aerated concrete block,concrete block machine,light weight block

1 Product weight is according to **0kg/m3 to control.

2 annual capacity **0,**0M3.

3 set raw material proportion: cement 6.5%, raw lime *3%, flyash *8%, gypsum 3%, aluminum paste powder **0g/M3.

4 water and material rate 0.**1

5 one mould product 2.*8M3

6 Casting slurry cycle time **6 minutes, cut cycle time 5 minutes.

7 casting slurry temperature ****2 degree

8 body quiet stop. Time is 1.**2.5housr, temperature ****0 degree, after quiet stop body strength is 0.***0.*8Mpa

9 Steam curing cycle time, come in and out autoclave about 0.5hour, steam curing cycle time about is 6 hours/1.6Mpa, total 6.5 hours.

*0. Cement lime fly ash style aerated block raw material proportion

|

name |

unit |

Cement lime fly ash |

|

flash |

% |

****0 |

|

cement |

% |

***5 |

|

lime |

% |

****5 |

|

gypsum |

% |

**5 |

|

Aluminum powder paste(**0kg/m3) |

1/****0 |

8 |

|

Water & material rate |

|

0.***0.*5 |

|

Casting system |

OC |

****0 |

|

Aluminum mixing time |

S |

****0 |

*1. Cement lime Sand style aerated block raw material proportion

|

Name |

Unit |

Cement Lime Sand |

|

Sand |

% |

****5 |

|

Cement |

% |

****0 |

|

Lime |

% |

****0 |

|

Gypsum |

% |

**3 |

|

Aluminum powder paste(**0kg/m3) |

1/****0 |

8 |

|

Water & material rate |

|

0.***0.*5 |

|

Casting system |

OC |

****8 |

|

Aluminum mixing time |

S |

****0 |

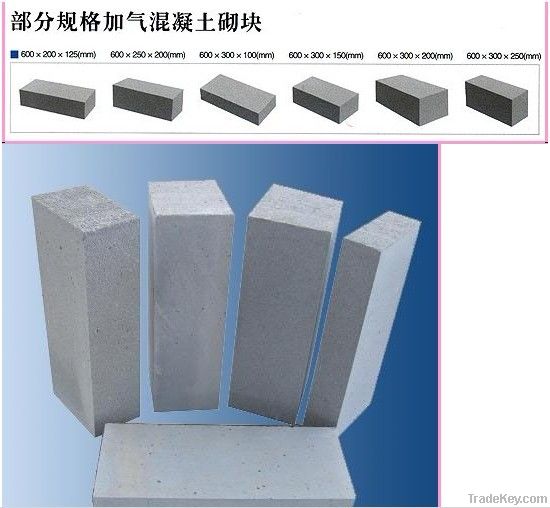

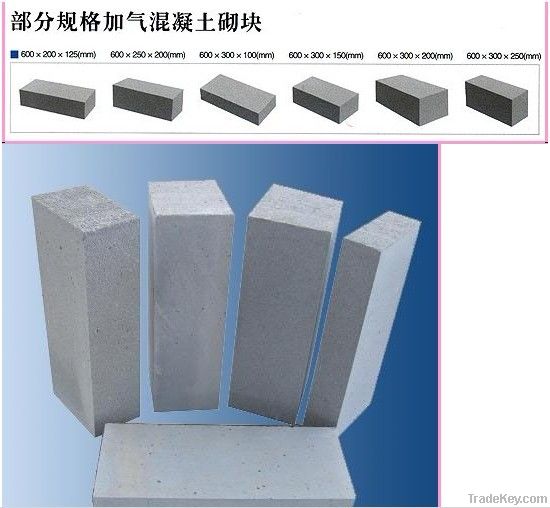

Autoclaved aerated concrete(light brick) is the light and porous buidling material.It has light keeping temperature cant burn and other advantages . it can be made into many kinds of bricks

Aerial tumbling cutting units are very most equipments for AAC production line . Its production process is simple and easy to operate .Our aerated concrete is fully automatic intelligent production line .

We provide aac casting machine with good quality,service and all full-automatic autoclaved aerated concrete block produce equipment,like sand aac block machine and fly ash aac block machine with different capacity.

The autoclave is applicable for curing the cut body under high temperature and high pressure, and is also applicable for curing the autoclaved brick under high temperature and high pressure.

Cutting machine is the main equipment for AAC block machine production line .Our HJQ-A cutting with advanced technology ,can make the block with only one step ,turning cut the six sides.

Ingredients center ,store slurry tank and friction wheel ,they are corollary equipmens for AAC block machine production line or AAC block machine .Easy operation, all the electric control

Finished product bricks were shipped the autoclaved kettle ,Use snapping trigger separate adhesion together of the brick .Then automatic packaging machine starts vacuum packing machine ,don't need manual operation ,save time and labour,improve efficiency ,it is a right-hand man for aerated concrete advanced equipments .

This is the latest flip hoist , one of the equipments for AAC block machine production line . It is a right-hand man for Aerial tumbling cutting units .

(light brick) is the light and porous buidling material.it is named AAC block . It has light keeping temperature cant burn and other advantages . it can be made into many kinds of bricks .AAC blocks have the trend to replace the clay brick completely in the future.

In the third stage of aac block machine production line ,we need use mold/mould and side plate,for the aac block casting and maintenance.

We have autoclave aerated concrete production line from **0,**0 m3 to **0,**0 m3 annual capacity .Steaming larry is an accessory equipment for aac block machine production line.

Our MD type pulse-bag dust collectors,which are ideal equipment used for dust control in building material,chemical industry,coal,tobacco and foodstuff,etc.

| Country: | China |

| Model No: | 150000cubic meter annual |

| FOB Price: | 100000 ~ 100001 / Set Get Latest Price |

| Place of Origin: | china |

| Price for Minimum Order: | 100000 per Set |

| Minimum Order Quantity: | 4 Set |

| Packaging Detail: | wood box |

| Delivery Time: | 20 days |

| Supplying Ability: | 4 Set per Week |

| Payment Type: | T/T, L/C, D/A, D/P |

| Product Group : | Autoclave Aerated Concrete Equipment |