Our company has been engaged in the refractory

materials industry for many years, focusing on the in-depth

research, development, production, sales, and service of

refractory materials. Currently, we have established a complete

set of management models, production, and quality control

systems. In recent years, with the rapid development of the

refractory materials industry, the demand for quality and variety

has been continuously increasing.

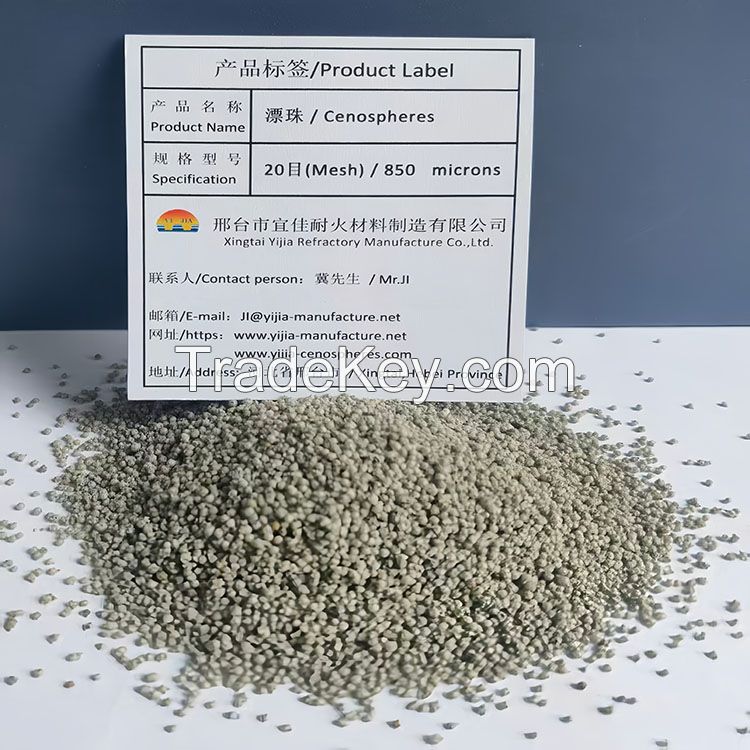

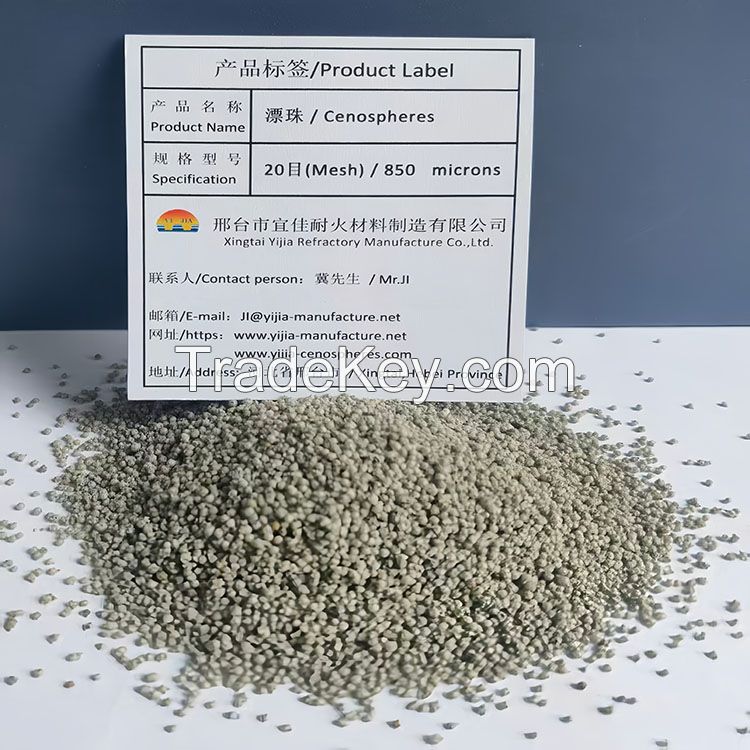

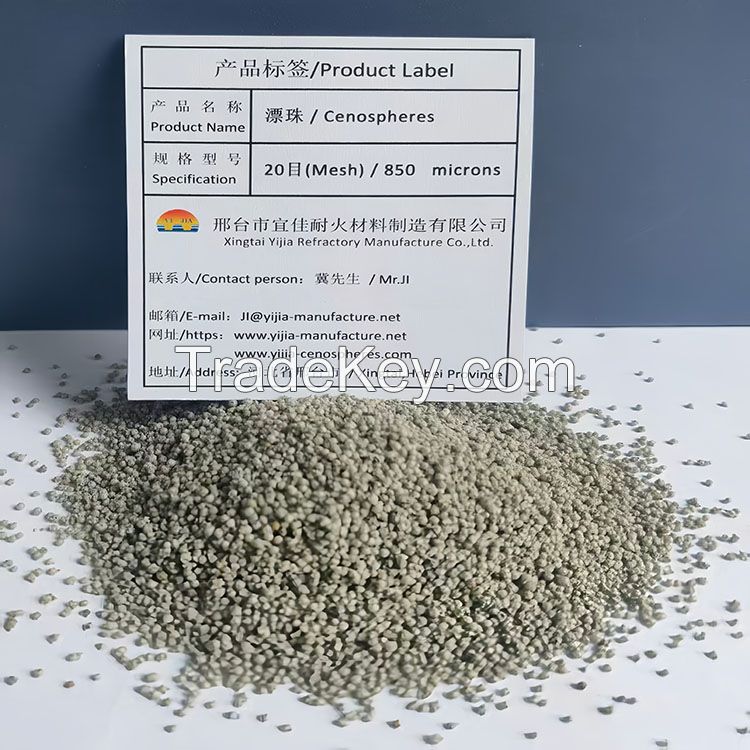

Cenospheres are grayish-white spherical in

appearance and possess multiple properties such as fine

particles, light weight, high strength, wear resistance, low

thermal conductivity, high refractoriness, thermal insulation,

electrical insulation, and uniform stress and strain. They are

widely used as reinforcing fillers in fields such as refractory

and thermal insulation materials, plastics, coatings, foundry,

ceramics, and petroleum drilling. They can not only effectively

improve product performance or construction results but also

significantly reduce production costs.

I.Cenosphere's chemical

composition:

|

composition

|

SiO₂

|

Al₂O₃

|

Fe₂O₃

|

SO₃

|

|

content(%)

|

****5

|

****6

|

0.**1.5

|

0.**0.2

|

II.Cenosphere's physical

properties:

|

item

|

test specification

|

item

|

Test specification

|

|

shape

|

High flowability

spherical powder

|

Granularity(mesh)

|

*****0mesh

|

|

color

|

Light grayish

white

|

Moh's hardness

|

**7

|

|

True

density(g/ml)

|

0.**1.1

|

Melting

point(℃)

|

≥***0

|

|

stacking

density(g/cm³)

|

0.***0.*6

|

refractoriness(℃)

|

********0

|

III.

Characteristics of Cenospheres:

1.High

refractoriness:The main chemical components of

cenospheres are oxides of silicon and aluminum. Since the

melting point of silicon dioxide is as high as ***5 degrees

Celsius, and the melting point of aluminum trioxide is ***0

degrees Celsius, both are high refractory substances.

Therefore, cenospheres have extremely high

refractoriness.

2.Lightweight, thermal

insulation: Cenospheres have thin walls and hollow

interiors, with a semi-vacuum inside the cavity, resulting in

extremely slow and minimal heat conduction. They are not only

lightweight but also have excellent thermal insulation

properties.

3.High hardness and

strength: Because cenospheres are hard glass

bodies formed by silicon-aluminum oxide mineral phases (quartz

and mullite), their hardness can reach Mohs **7, and their

static pressure strength is as high as *****0MPa, thus having

high strength.

4.Insulating and

non-conductive: The

resistance of general insulators decreases with the increase of

temperature, but high-strength cenospheres are the opposite,

with resistance increasing as temperature rises. This advantage

is not possessed by other insulating materials. Therefore, it

can be made into insulating materials with excellent

performance.

5.Fine particle size and large specific

surface area:The naturally formed particle size of

high-strength cenospheres is *****5 microns. The specific

surface area is ******0 g/cm²,

which is equivalent to that of cement. It can be used directly

without grinding. The fineness can meet the needs of various

products.

IV. Uses

of Cenospheres:

1.Refractory and thermal insulation

materials: Such

as lightweight sintered refractory bricks, lightweight

non-fired refractory bricks, casting insulation risers,

pipeline insulation shells, fireproof and thermal insulation

coatings, thermal insulation pastes, composite thermal

insulation dry powders, lightweight thermal insulation and

wear-resistant glass fiber reinforced

plastics.

2.Building

materials: Building decoration, high-grade pavement

materials, roof waterproof and thermal insulation coatings,

modified asphalt, etc.

3.Petroleum

industry: Oilfield cementing, pipeline

anti-corrosion and insulation, offshore oilfields, floating

devices, oil well drilling mud lightening agents, oil and gas

transmission pipelines, etc.

4.Insulating materials; Plastic activated

fillers, high-temperature and high-pressure insulators,

etc.

5.Coating

industry: Paints, inks, adhesives, stealth

coatings, insulating paints, anti-corrosion paints, floor

paints, high-temperature resistant and fireproof paints,

interior and exterior wall coatings, thermal insulation

coatings, floor paints, automotive putties, atomic ash,

etc.

6.Plastic

industry: Such

as automotive trim parts, instrument panels, home appliance

casings, fans, speakers, lamp assemblies, plates,

etc.

7.Glass fiber reinforced plastic products:

Various glass fiber reinforced plastic products, artificial

marble, glass fiber reinforced plastic ships, handicrafts,

etc.

8.Encapsulation materials: Transformer

potting materials, electronic encapsulation materials,

etc.