FOB Price

Get Latest Price1000 ~ 1000 USD / Set

|1 Set Minimum Order

Country:

China

Model No:

-

FOB Price:

1000 ~ 1000 USD / Set Get Latest Price

Place of Origin:

Jiangsu China

Price for Minimum Order:

1000 per Set

Minimum Order Quantity:

1 Set

Packaging Detail:

wooden box

Delivery Time:

7-10 days

Supplying Ability:

300 Set per Year

Payment Type:

T/T, PayPal, Other

Product Group :

Contact Person Mr. james

No.318 Kunjia Road, Suzhou, Jiangsu

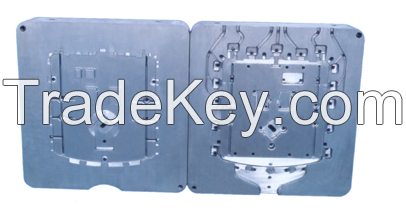

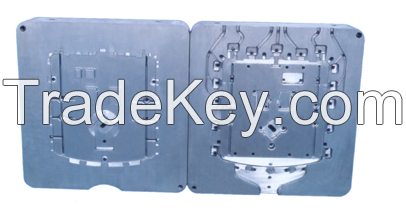

Die Casting Mold

A die casting mold is a tool used in the die casting process, where molten metal is injected into a mold cavity under high pressure to form a solidified part. This process is widely used in the manufacturing of complex metal parts for industries such as automotive, electronics, aerospace, and more.

Key Features:A die casting mold is a tool used in the die casting process to create high-precision, durable metal parts. It enables the mass production of complex metal components with excellent surface finishes, high strength, and minimal waste. Die casting is essential in industries like automotive, aerospace, and electronics, where quality, efficiency, and cost-effectiveness are critical.

| Country: | China |

| Model No: | - |

| FOB Price: | 1000 ~ 1000 / Set Get Latest Price |

| Place of Origin: | Jiangsu China |

| Price for Minimum Order: | 1000 per Set |

| Minimum Order Quantity: | 1 Set |

| Packaging Detail: | wooden box |

| Delivery Time: | 7-10 days |

| Supplying Ability: | 300 Set per Year |

| Payment Type: | T/T, PayPal, Other |

| Product Group : | mould |