FOB Price

Get Latest Price|

- Minimum Order

Country:

China

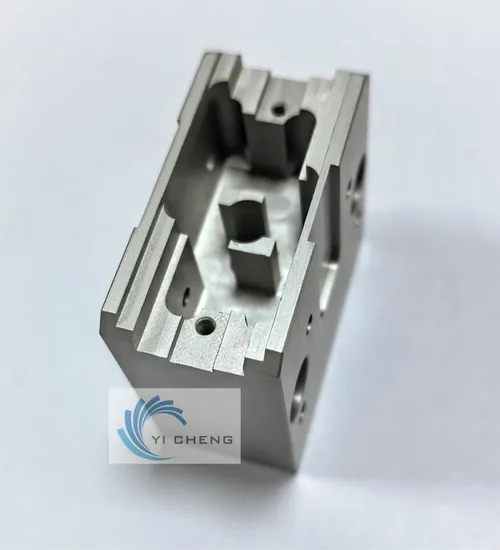

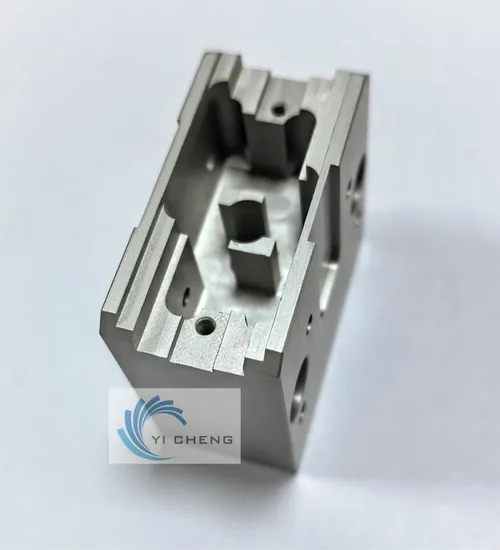

Model No:

MC-119

FOB Price:

Place of Origin:

-

Price for Minimum Order:

-

Minimum Order Quantity:

-

Packaging Detail:

-

Delivery Time:

-

Supplying Ability:

-

Payment Type:

-

Product Group :

-

Tungsten Carbide Grades (Properties and Application)

|

Grade |

WC% |

Co/Ni% |

Physical and mechanical properties |

Grain size μm |

Recommended application |

||

|

Density g/cm3 |

TRS N/mm2 |

Hardness HRA |

|||||

| ZG01 | 100 | 0 Co | 15.3-15.5 | 1200 | 95.5 | 0.3 | Ultra high hardness, high wear resistance, corrosion resistance, with certain damage resistance |

| ZG04X | 96 | 4 Co | 15.0-15.2 | 1600 | 92.8 | 0.8-1.0 | Suitable for wire drawing die, non-ferrous metal wire tensile wear-resisting parts |

| ZG06 | 94 | 6 Co | 14.8-15.1 | 2500 | 90.0 | 1.2 |

Good wear resistance, good compression resistance, suitable for wear resistance and high pressure resistance parts, good thermal rigidity |

| ZG06X | 94 | 6 Co | 14.8-15.1 | 2400 | 91.5 | 1.0 | |

| ZG06A | 94 | 6 Co | 14.8-15.1 | 2150 | 92.5 | 0.6-0.8 | |

| ZG08 | 92 | 8 Co | 14.6-14.9 | 2700 | 89.0 | 1.2-1.6 | Good general performance, used for usual wear - resistant parts, molds, general tools, etc |

| ZG10.2 | 90 | 10 Co | 14.3-14.6 | 3800 | 91.8 | 0.7 | Sub-fine tungsten carbide particles, good general performance |

| ZG10X | 90 | 10 Co | 14.3-14.6 | 4000 | 92.2 | 0.6 | Ultra fine tungsten carbide particles, excellent heat resistance |

|

ZG11 |

89 |

11 Co |

14.3-14.7 |

2800 |

88.5 |

1.2-1.6 |

Anti-wear, anti-erosion, good comprehensive mechanical strength, suitable for wear-resistant parts in the petroleum, chemical and mechanical industries. |

| Country: | China |

| Model No: | MC-119 |

| FOB Price: | Get Latest Price |

| Place of Origin: | - |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | - |

| Packaging Detail: | - |

| Delivery Time: | - |

| Supplying Ability: | - |

| Payment Type: | - |

| Product Group : | - |