FOB Price

Get Latest Price6.5 ~ 8.5 USD / Roll ( Negotiable )

|1000 Roll Minimum Order

Country:

Vietnam

Model No:

Tracy cocofibernet- H1288

FOB Price:

6.5 ~ 8.5 USD / Roll ( Negotiable ) Get Latest Price

Place of Origin:

Vietnam

Price for Minimum Order:

6.5 per Roll

Minimum Order Quantity:

1000 Roll

Packaging Detail:

customer's request

Delivery Time:

10 to 15 days

Supplying Ability:

10000 Roll per Day

Payment Type:

T/T, L/C, Western Union

Product Group :

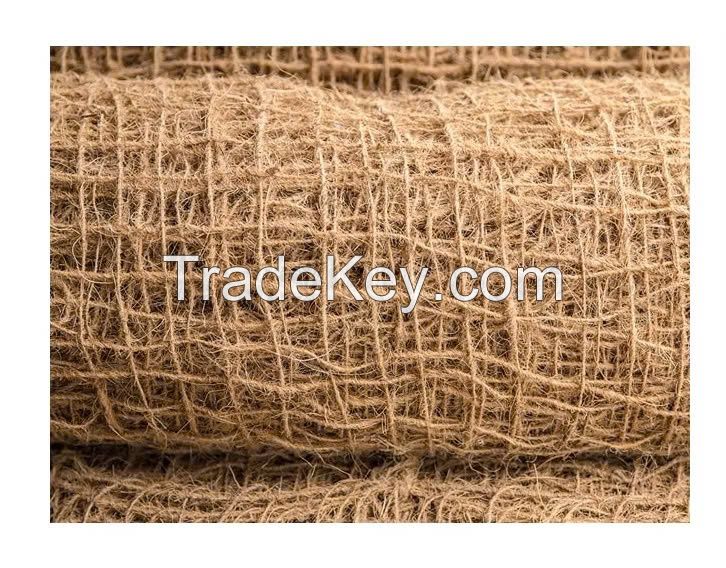

Coconut fiber, or coir, is a natural material extracted from the husk of coconuts. It is widely known for its durability, water retention properties, and eco-friendliness. One of the most versatile applications of coconut fiber is in the production of coconut fiber nets, also called coir nets. These nets are used in various industries, including agriculture, landscaping, erosion control, and horticulture, due to their ability to promote plant growth, prevent soil erosion, and offer an environmentally sustainable alternative to synthetic materials.

Coconut fiber nets are made by weaving coir fibers into a mesh structure, creating a grid-like pattern that is flexible yet strong. These nets are biodegradable, durable, and have excellent water retention properties, making them a preferred choice for applications where soil stabilization, plant growth, and environmental conservation are key concerns.

Composition and StructureThe primary material used in the construction of coconut fiber nets is coir, which is extracted from the outer husk of mature coconuts. The coir fibers are long, thick, and highly resistant to saltwater and microorganisms, making them ideal for both coastal and inland applications.

A typical coconut fiber net consists of tightly woven coir fibers, which are arranged in a grid or mesh-like pattern. The size of the grid can vary depending on the intended application, with some nets featuring large, open spaces between the fibers, and others having a denser, tighter weave. The thickness and density of the net are determined by the amount of fiber used and the weaving technique employed.

Coconut fiber nets are available in different grades and types, depending on the level of durability, water retention, and strength required. Some nets are reinforced with additional materials, such as jute or natural ropes, to enhance their strength and longevity, especially for applications where greater durability is necessary.

Production Process

Harvesting and Fiber Extraction:

The production of coconut fiber nets begins with the

harvesting of mature coconuts. Once the coconuts are

harvested, the husks are separated from the fruit. These

husks contain both long and short fibers, which are soaked in

water to soften them. After soaking, the fibers are

extracted, cleaned, and dried.

Fiber Preparation and Spinning:

The coir fibers are then spun into yarn, which forms the

basic material for creating the coconut fiber nets. The

spinning process ensures that the fibers are aligned

properly, providing the necessary strength and durability to

the net. In some cases, additional treatments such as boiling

or chemical processing are applied to the fibers to enhance

their resistance to pests and decay.

Weaving the Nets:

Once the coir yarn is prepared, it is woven into a net using

either manual or mechanical looms. The weaving process

involves intertwining the fibers into a grid pattern, with

the size of the grid varying according to the specific

application. Handwoven nets are typically used for artisanal

or specialized applications, while machine-made nets are

preferred for large-scale industrial use.

Finishing and Quality Control:

After weaving, the coconut fiber nets undergo a finishing

process, where they are checked for quality, uniformity, and

strength. Any irregularities are corrected, and the nets are

treated to ensure that they are free from impurities and

moisture. The finished product is then packaged and stored

for distribution.

Coconut fiber nets are highly versatile and find applications in various sectors, including:

Soil Erosion Control:

One of the most common uses of coconut fiber nets is in

controlling soil erosion, particularly on slopes, riverbanks,

and coastal areas. The nets are laid over the surface of the

soil, where they act as a protective layer that stabilizes

the soil and prevents it from being washed away by rain,

wind, or water currents. Over time, the coir net biodegrades,

allowing vegetation to grow through the mesh and further

stabilize the soil.

Landscaping and Green Infrastructure:

In landscaping and urban development projects, coconut fiber

nets are used to create green infrastructure solutions, such

as living walls, green roofs, and vertical gardens. The coir

fibers help retain moisture and provide a natural growing

medium for plants, making them ideal for use in areas where

natural vegetation is encouraged.

Agriculture and Horticulture:

In agriculture, coconut fiber nets are used as a ground cover

to suppress weeds, retain soil moisture, and promote healthy

plant growth. They provide a biodegradable alternative to

synthetic weed control fabrics and plastic mulch. In

horticulture, they are used as a substrate for hydroponic

growing systems, where their water retention and air

permeability properties are beneficial for plant root

systems.

Construction and Civil Engineering:

Coconut fiber nets are often used in construction and civil

engineering projects to provide temporary support for soil

and plants. For example, they are employed in the

construction of embankments, where they offer short-term

protection while the vegetation establishes itself and

stabilizes the structure. In road construction, coconut fiber

nets help protect freshly graded slopes from erosion until

permanent vegetation takes hold.

Coastal and Wetland Restoration:

In coastal areas and wetlands, coconut fiber nets are used to

protect shorelines and prevent the loss of valuable wetland

ecosystems. The nets are laid along the shoreline to

stabilize the soil and promote the growth of salt-tolerant

plants, which further help to anchor the soil in place. This

technique is particularly useful in areas prone to coastal

erosion and rising sea levels.

Wildlife Habitats and Conservation

Projects:

In wildlife habitats and conservation projects, coconut fiber

nets are used to create natural environments that support

plant and animal life. The biodegradable nature of coir

ensures that the nets do not harm wildlife, and as they

decompose, they contribute organic material to the soil,

enriching it and promoting biodiversity.

Eco-Friendly and Sustainable:

Coconut fiber nets are an environmentally friendly

alternative to synthetic materials. Coir is a renewable

resource, as coconuts are harvested multiple times per year,

and the production process has a low environmental impact.

Furthermore, the nets are fully biodegradable, decomposing

naturally over time and leaving no harmful residues in the

soil.

Water Retention and Air Permeability:

Coir fibers have excellent water retention properties, which

makes coconut fiber nets highly effective in retaining

moisture and preventing soil dehydration. This is

particularly useful in areas with dry climates or where water

conservation is a priority. At the same time, the nets porous

structure allows air to circulate freely, promoting healthy

root growth for plants.

Durability and Strength:

Despite being a natural material, coconut fiber is remarkably

strong and durable. Coir fibers are resistant to rot,

saltwater, and microorganisms, making them suitable for

long-term outdoor use in a variety of environmental

conditions, from arid regions to coastal areas.

Biodegradability:

One of the most significant benefits of coconut fiber nets is

their biodegradability. Over time, the nets break down

naturally, enriching the soil with organic material. This

eliminates the need for removal and disposal, which is often

required with synthetic erosion control products.

Cost-Effective:

Coconut fiber nets offer a cost-effective solution for

erosion control, landscaping, and agricultural applications.

Their long lifespan and low maintenance requirements make

them a budget-friendly option, particularly when compared to

synthetic alternatives that may require frequent replacement

or removal.

Encourages Vegetation Growth:

The grid-like structure of coconut fiber nets allows plants

to grow through the mesh, creating a natural and stable

environment for vegetation. This is particularly useful in

erosion control projects, where the growth of vegetation

helps to anchor the soil and prevent further erosion.

The use of coconut fiber nets aligns with the growing global trend toward sustainability and environmental conservation. The production of coir does not harm the environment, as it is a byproduct of the coconut industry, which itself is a sustainable agricultural practice. The fibers are extracted using traditional methods that require minimal energy and no harmful chemicals.

Moreover, coconut fiber nets help reduce the environmental impact of erosion control and landscaping projects by providing a natural, biodegradable solution that does not contribute to plastic pollution. As they decompose, the coir fibers enrich the soil with organic matter, improving soil quality and promoting plant growth.

ConclusionCoconut fiber nets are a sustainable, eco-friendly, and highly versatile product that offers numerous benefits for a wide range of industries. From soil erosion control and landscaping to agriculture and coastal restoration, these nets provide an effective and environmentally responsible solution. Their durability, water retention capabilities, and biodegradability make them a superior alternative to synthetic materials, aligning with modern trends toward sustainable and green infrastructure solutions. As the world continues to prioritize environmental conservation, the demand for products like coconut fiber nets is likely to grow, cementing their place as a key tool in sustainable development projects.

| Country: | Vietnam |

| Model No: | Tracy cocofibernet- H1288 |

| FOB Price: | 6.5 ~ 8.5 / Roll ( Negotiable ) Get Latest Price |

| Place of Origin: | Vietnam |

| Price for Minimum Order: | 6.5 per Roll |

| Minimum Order Quantity: | 1000 Roll |

| Packaging Detail: | customer's request |

| Delivery Time: | 10 to 15 days |

| Supplying Ability: | 10000 Roll per Day |

| Payment Type: | T/T, L/C, Western Union |

| Product Group : | agriculture |