No.506 West Huanghe Avenue,Hong Kong,Central and Western,China China

Contact Person Ms. Meiling

Address No.506 West Huanghe Avenue, Hong Kong, Central and Western, China

Contact Now Rate this company Report Fraud

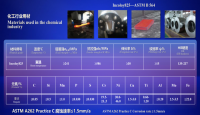

Nickle alloy products

Nickle alloy products

ERNiCrMo-3 / Inconel 625 Welding Wire

ERNiCrMo-3 / Inconel 625 Welding Wire

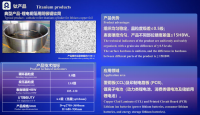

Titanium Alloy Products

Titanium Alloy Products

Copper-Nickel Slag Recycled Copper Alloys

Copper-Nickel Slag Recycled Copper Alloys

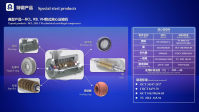

Compressor parts

Compressor parts

Casting and Forging Parts

Casting and Forging Parts

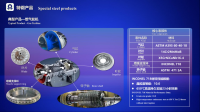

Gas turbine parts

Gas turbine parts

5t electro-hydraulic hammer

5t electro-hydraulic hammer

10MN fast forging hydraulic unit

10MN fast forging hydraulic unit

50MN fast forging hydraulic unit

50MN fast forging hydraulic unit

125MN fast forging hydraulic unit

125MN fast forging hydraulic unit

125MN fast forging hydraulic unit

125MN fast forging hydraulic unit

5G crane intelligent batching system

5G crane intelligent batching system

5t 15t Superalloy Induction Melting Furnace

5t 15t Superalloy Induction Melting Furnace

10t and 30t electric arc furnaces

10t and 30t electric arc furnaces

10t AOD refining furnace

10t AOD refining furnace

20t electric arc furnace

20t electric arc furnace

20t VODC AOD

20t VODC AOD

30t VD VOD refining furnace

30t VD VOD refining furnace

45t, LF refining furnace

45t, LF refining furnace

500kg, 4t electric switch remelting furnace

500kg, 4t electric switch remelting furnace

Intelligent online pouring

Intelligent online pouring

Intelligent pouring system

Intelligent pouring system

| Business Type | Manufacturing |

| Website | http://www.lshengchang.com.cn |

| Year Established | 2023 |

| Number of Employees | 101-500 |

| Main Markets | Africa,Asia,America,Europe,Middle East,Worldwide |

| Products / Services | nickle alloy,titanium alloy,copper alloy,castings and forgings. |

| Factory Location | China |

| Factory Size | 10000 sqm to 250000 sqm |

| No. of Production Lines | 0 |

| Total Annual Purchase Volume | N/A |

| No. of R&D Staff | 21 - 30 people |

| Quality Control | In House |

| Certificates | ISO-9001 |

| Contract Manufacturing | OEM Service Offered ,Design Service Offered,Buyer Label Offered |

| Registered Capital | 2.5 - 10 Million USD |

| Ownership Type | LLC (Limited Liability Corp) |

| Legal Representative / CEO | Yu Ling |

| Export Percentage | 30% |

| Total Annual Sales Volume | 2.5 - 10 Million USD |

| No. of QC Staff | N/A |

| Contact Person | Ms. Meiling |

| Company | Lanzhou Lanshi Heng Chang Metal Material Co., Ltd. |

| Telephone | ******** |

| Mobile | ******** |

| Fax | ******** |