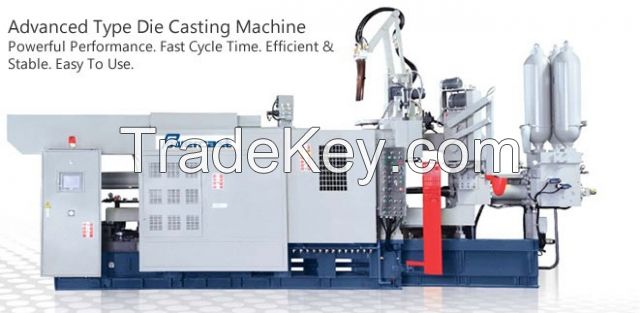

Description

●

Injection valve is controlled

electronically. Injection pressure can be detected. Digitized

injection stroke, simple design, stable

casting.

● With smart quality control system, injection

curve is recorded automatically during injection. Raising an

alarm for abnormality, make sure quality consistency,

stability of large-scale production.

● Injection parameters save up to **0

sets

● Providing ***0 sets injection data (production

resume) display. Injection data is recorded automatically.

Injection data can also be stored effectively in USB flash drive

for future references and comparison

● Die cast conditions can be stored and managed.

Data of die cast conditions can be backed up and stored in USB

flash drive to prevent data loss.

● Dry shot speed: 7

m/sec

● Non-contact magnetic sensor for injection

position.

● Auto extractor lateral movement is adjusted

electrically.

● Molten metal volume of auto ladler can be

calculated and set from touch screen.

● Cycle time can be set and

monitored.

● Core movements is controlled by Limit Switch /

Timer.

● Injection terms

calculating.

● Pressure quick relieve

valve.

●Auto

tie bar puller in operator side (Available for **0T machines &

above)

Vacuum system

interface

Digital die locking

force

display

●Quick

mold change

system

●Core

3

Squeeze pin

interface

●-

Melting

device ●Platen

side-spray