FOB Price

Get Latest Price( Negotiable )

|1 Set Minimum Order

Country:

China

Model No:

SHJ-65

FOB Price:

( Negotiable ) Get Latest Price

Place of Origin:

Jiangning district, nanjing city

Price for Minimum Order:

-

Minimum Order Quantity:

1 Set

Packaging Detail:

Wooden case package

Delivery Time:

Within 50 days

Supplying Ability:

12 Set per Month

Payment Type:

L/C, T/T

Product Group :

Contact Person Ms. Becky

Weiqi street, Nanjing, Jiangsu

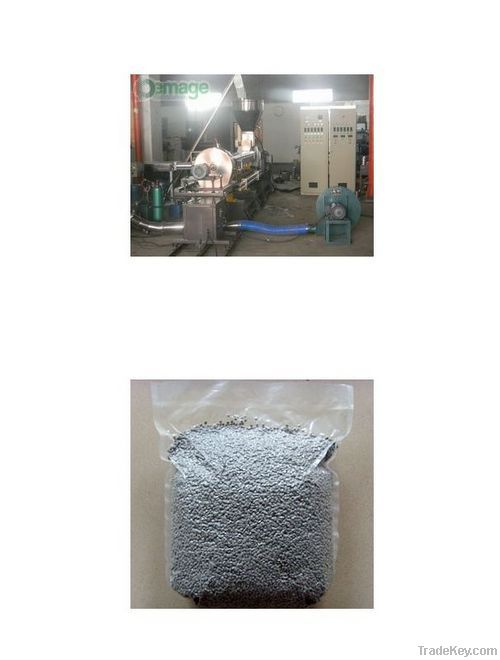

Anti-foaming Masterbatches it was also known as Defoamer. Plastic

product including extrusion, injection and film process is made of

plastic raw material melt with high temperature by extrusion molding

equipments. The quality of plastic product is directly and closely

related to the compaction and drawback rate for molding product.

The moisture content in raw material will directly impact to the

quality of plastic product. The moisture will become steam in the

process of plastic product and lead to drawback with bubble,

crackle, spot and hole in plastic product, so that it influence the

mechanics property and appearance of plastic product.

Introduction

Anti-foaming masterbatches is non-toxic, non-contamination, no influence to property for plastic product. In the

process of molding, anti-foaming masterbatches can strongly absorb the moisture in plastic

raw materials. It can increase product quality and the rate of

finished products, improve obviously productivity and reduce

energy consumption.

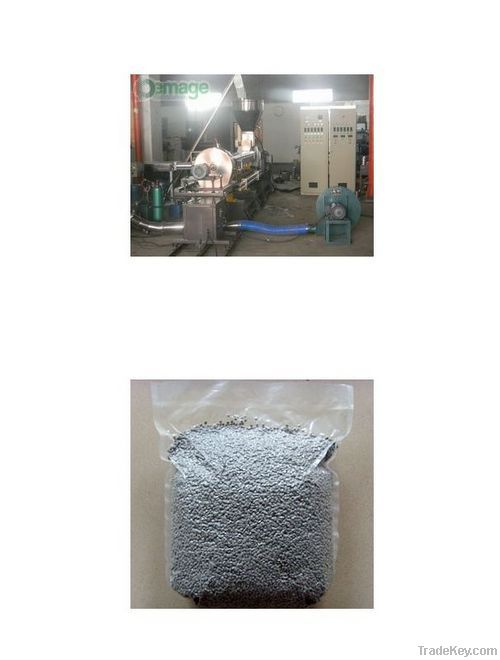

Air-cooling die face hot-cutting

Air-cooling die face pelletizing mainly used in materials whose moisture can

easily result in product poor quality. Since the material has no contact

with water in the whole granulation process, so eliminating the dehydration

part, to avoid the second pollution of cooling water. The die face hot-cutting material particles look round, full and beautiful.

Application:

1. Enhanced modification: PE, EVA, etc. with calcium sulfate, talc,

titanium dioxide, carbon black;

2. Biodegradable Masterbatch: PE, PS etc. with starch, additives, etc.;

3. Flame retardant masterbatch: PE, EVA, etc. with antimony trioxide,

magnesium hydroxide, aluminum hydroxide.

Main configuration:

Extruder mouth template, granulator, and cyclone separator and it’s air

conveying system, vibrating screen and follow-up storage system.

| Country: | China |

| Model No: | SHJ-65 |

| FOB Price: | ( Negotiable ) Get Latest Price |

| Place of Origin: | Jiangning district, nanjing city |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | 1 Set |

| Packaging Detail: | Wooden case package |

| Delivery Time: | Within 50 days |

| Supplying Ability: | 12 Set per Month |

| Payment Type: | L/C, T/T |

| Product Group : | Color masterbatch plastic extruder |