FOB Price

Get Latest Price80000 ~ 400000 USD / Set ( Negotiable )

|1 Set Minimum Order

Country:

China

Model No:

JMB

FOB Price:

80000 ~ 400000 USD / Set ( Negotiable ) Get Latest Price

Place of Origin:

no. 88 Chuangxin Road Xindai Town Pinghu City Zhej

Price for Minimum Order:

80000 per Set

Minimum Order Quantity:

1 Set

Packaging Detail:

wooden case

Delivery Time:

90 days

Supplying Ability:

3 Set per Month

Payment Type:

Western Union, L/C, T/T

Product Group :

Contact Person Mr. Garry

Lixue Road, Shanghai, Shanghai

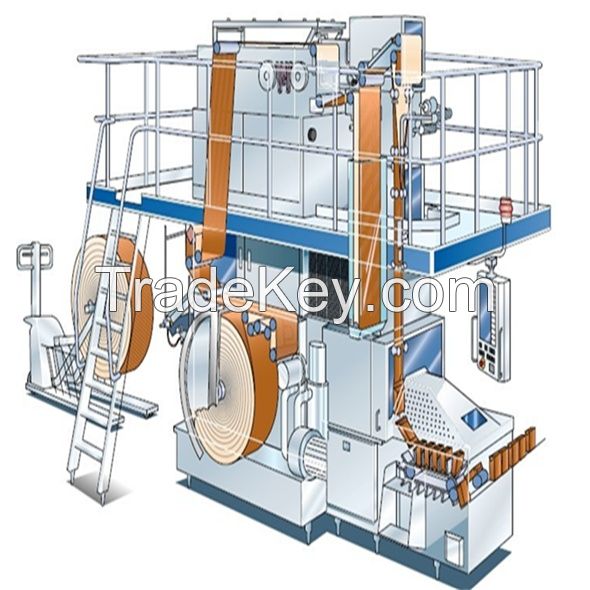

A: Features of the equipment

1. Description of equipment

(1) Paper feeding, sterilization, box making, filling,

molding and sealing are made automatically, the molding of

composite materials using hydrogen peroxide spray and

high-intensity ultraviolet radiation and sterile hot air drying,

packing, materials completion of the aseptic chamber of the filling

and after the filling of the seal are in a positive pressure

conditions, thus ensure a sterile packing and the packed juice

beverage, after the UHT sterilization at room temperature, long up

to one year for shelf life. In addition, the aircraft PLC optical

correction, frequency control, pneumatic solenoid valve, vacuum

systems, liquid level control, smart electronic thermostat

adjustment, automatic fault alarm system and sterile room, etc. use

the famous brands in Germany, Japan and other countries, which is

used stainless steel for the whole machine, with beautiful

appearance and convenient operation.

(2) We choose roll extrusion in mechanical transmission

multilayer push-draw mode as the carton conveyer for the fixed

amount, cutting carton and forming.

(3) We adopt rectangular forming method and device as forming

system which makes the function much more reliable, the exterior

appearance of the product much perfect.

(4)Automatically finish all the packing steps, including

running over the scroll reposefully, pre-sticking the sealing

strip, stick plastic tape, chemical and physical sterilizing,

pre-forming cylinder, filling, sealing in cross direction, molding,

cutting, sticking angle and delivery.

(5) This design blends into modern up-to-date technology of

optical, mechanical and electronic integration, integrated design

and skillful manufacture. Closed loop to control the tension,

opto-electricity detection, PLC control, monitoring and operation

on touching human-machine interface, radiant heat and high

frequency induction heating are adopted skillfully to make

the sealing much firm and reliable in cross and vertical

direction.

(6) The main transmission is mechanical and the auxiliary

drive is vapor-pressure type.

(7) Changing the scroll without stop operating for a special

design which can change the scroll freely under the operating

situation.

2. Molding diagram for packaging

B:

Technical parameters

1. Filling speed: 6000 bags/h

2. Sealing type: Rolling chain

3. Technological process: Paper feeding

sterilizefillingshaping-print date

4. Filling temperature: 25~30 ºC

5. Package form: Standard type and slim type

6. Package capacity: 200 ml ~250 ml

7. Package material: Six layer drum composite materials for paper

aluminum PE film

8. Power supply: 220V/380V-50 Hz/60 Hz, Total power: 40

KW

9. Pressure for compressed air: 0.8~1.2 Mpa, usage of compressed

air: 1M3/min

10. Steam supply pressure: 0.14~0.2 Mpa, steam temperature: 130 ºC,

steam consumption: 3.5 Kg/H

11. Supply pressure of cooling water: 0.3~0.45 Mpa, supply

temperature of cooling water is equal or lower than 20 ºC, cooling

water consumption: 40L/H

12. Concentration of hydrogen peroxide: 35~40%, hydrogen peroxide

temperature: 65~70 ºC, hydrogen peroxide consumption:

4L/H

C: 3 D diagram of equipment

D: Equipment configuration

| No. | Name | Configuration | Quantity | Brand |

| 1. Mechanical molding | ||||

| 101 | Lower traction part |

One worm gear and worm reducer NARV50-15 as main traction roller with 0.37 KW of three-phase asynchronous motor; One Japan SMC cylinder MA40x35 as traction rubber roller |

One set | Japan Inovance gear motor |

| 102 | Locating mechanism | Oner Japan SMC compact cylinder SDA40x15 for break | One set | |

| 103 | Tectorial membrane mechanism | One Japan SMC air cylinder MA16x30 as rubber roller for pressed PP film | One set | |

| 104 | Mechanism for putting mould | One set Germany Igus guide rail; two mold-receiving cylinder SDA12x12; ceramic membrane heater with PTC heating piece | One set | |

| 105 | Idler pulley mechanism | Japan HRC55-60 pin roll, for all stainless steel hard shaft, with heat treatment of the surface; Germany Igus for cover of pin roll |

One set |

|

| 106 | Transverse sealing frame | Aviation aluminum 7075for frame material | One set | |

| 107 | Transverse sealing clamp claw | United States dupont engineering plastics;stainless steel for key components with heat treatment; Japan NSK bearing; Japan Inovance para-position motor (0.75 KW); U.S. C17200 beryllium bronze for transverse sealing electrode parts | One set | |

| 108 | Transverse sealing clamp claw motor | 4.4 KW of Japan Inovance servo motor | One set | |

| 109 | Station chain mechanism | 26 pieces of finishing chain plates, 7075 aviation aluminum for all material with oxidation treatment for surface | One set | |

| 110 | Outlet mechanism | Bevel gear reducer at 1:1 rate of APEX brand in Taiwan; cam machine structure for delivering package with turnplate, eight dial package swing arms in one ring, automatic telescopic package | One set | |

| 111 | Outlet mechanism motor | 4.4 KW of Japan Inovance servo motor | One set | |

| 112 | Upper traction mechanism |

Traction box bearing using Swedish SKF stainless steel

bearing which is high temperature resistant, corrosion

resistant, resistant to acid and alkali. One worm gear and

worm reducer NARV50-15 as main traction roller with 0.37KW

of three-phase asynchronous motor; One Japan SMC cylinder MA40x35 as traction rubber roller |

One set | Japan Inovance gear motor |

| 113 | Transverse high-frequency heater | 2 KW of high frequency electromagnetic induction, RDRF-05 | One piece | ItalyCEIA |

| 114 | Vertical sealing high-frequency heater |

2 KW of high frequency electromagnetic induction, RDRF-05 |

One piece | ItalyCEIA |

| 115 | Tectorial membrane high-frequency heater | 2 KW of high frequency electromagnetic induction, RDRF-05 | One piece | ItalyCEIA |

| 116 | Automatic lubrication tankers | 30W, Taiwan Tungtay | One set | |

| 2. Aseptic system | ||||

| 201 | Hot blast heater | 15KW | One piece | Japan SAKAGUCHI |

| 202 | Hydrogen peroxide tank machine | 316 material for hydrogen peroxide tank, inner roll barrel bearing using Japanese ceramic bearing | One set | |

| 203 |

Hydrogen peroxide pump |

0.37KW,300L/H | One set | GRUDFOS |

| 204 | Hydrogen peroxide heater | 2KW | Three pieces | Japan SAKAGUCHI |

| 205 | Water-ring vacuum pump | 4KW | One set | BECKER |

| 206 | Two-position three-way reversing valveof pneumatic | φ51.3 | Two pieces | APV |

| 207 | Plate heat exchanger | BRF05-160-316L | One set | SHANGHAI NANHUA |

| 208 | Temperature sensor | 0~200/450 | Five pieces | Omron |

| 209 | Ball valve, Butterfly valve, Angle seat valve |

Several |

Shanghai YuanAn | |

| 210 | Pressure regulating valve, safety valve | Each for one | APV | |

| 211 | Constant flow valve | Two pieces | APV | |

| 212 | Sterile proportional control valve | One piece | GermanyBURKERT | |

| 3. Electrical configuration | ||||

| 301 | Air circuit breaker | C65N-D | Schneider | |

| 302 | AC contactor | LC1-D****N |

Schneider |

|

| 303 |

Intermediate relay |

MY2NJ | Omron | |

| 304 | Frequency converter | ATV303H | Schneider | |

| 305 | Servo motor/ Servo driver | LSMH/LS600P | JapanInovance | |

| 306 | Programmable Controller PLC | S7-200CN | SIEMENS | |

| 307 | Human-computer interface | 6AV66480BE113AX0 | SIEMENS | |

| 308 | Temperature controller | PXR9NEH | Japan FUJI | |

| 309 | Voltage Regulator Module | STY**A-III | FuShenScience and Technology | |

| 310 | Proximity switch | LE**SF**DP0 | LABINO | |

| 311 | Magnetic switch | D-AS3 |

Japan |

|

| 312 | Color mark sensor | KT5W-2P2116D | SICK | |

| 313 | Absolute encoder | TRD-NA |

Japan |

|

| 314 | Switching mode power supply | Meanwell | ||

| Country: | China |

| Model No: | JMB |

| FOB Price: | 80000 ~ 400000 / Set ( Negotiable ) Get Latest Price |

| Place of Origin: | no. 88 Chuangxin Road Xindai Town Pinghu City Zhej |

| Price for Minimum Order: | 80000 per Set |

| Minimum Order Quantity: | 1 Set |

| Packaging Detail: | wooden case |

| Delivery Time: | 90 days |

| Supplying Ability: | 3 Set per Month |

| Payment Type: | Western Union, L/C, T/T |

| Product Group : | Filling and packing equipments |