Product Description

Superfine Powder Ball Mill &

Classifier Production Line Solution

Applications of Superfine Ball Mill &

Classifier Production Line:

Our superfine Ball Mill & Classifier production line can be

used for producing:

(1) Soft materials:

calcite, marble, limestone, kaolin, gesso, barite, coal ash and

slag, etc.

(2) Hard materials:

carborundum, brown corundum, superfine cement, zirconium sand,

and fire-proof materials, etc.

(3) High purity

materials: quartz, feldspar, α-alumina, glass fine bead,

etc.

(4) Metal powders: zinc

powder, aluminum powder, iron powder, and molybdenum powder,

etc.

Features of Superfine Ball Mill &

Classifier Production Line:

1. Low energy consumption: our superfine Ball Mill &

Classifier production line adopted high advanced energy-saving

technology and classification technique; as a result, our

production line can save over *0% energy for producing same

quantity materials.

2. Several times of classification could be obtained: Finished

product fineness after first time classification: *******0mesh;

if our Ball Mill & Classifier production line is equipped

with a second classification system, the finished product

fineness after second time classification would be 6,**0mesh

(d*7≤2um).

3. Adopted highly advanced self-diffluent classification system:

(1) The classifiers in

Ball Mill & Classifier production line have a precise

classification, so the produced materials have uniform

fineness;

(2) High classification

capacity: **0t/h;

(3) Low energy

consumption: For classifying the same quantity of raw materials,

a classifier in LHM Ball Mill & Classifier production line

can save about *0% energy comparing with traditional Ball Mill

& Classifier s.

(4) High classification

efficiency (*0% higher than classifiers in traditional grinding

mills)

4. Scientific grinding medium enable us to produce large quantity

superfine particles.

5. Different lining boards and grinding mediums are available for

milling different materials, so as to guarantee the purity and

whiteness of finished products.

6. Scientific machine structure enables a lower investment cost;

7. Low failure rate and stale operation: because our Ball Mill

and classifiers in the production lines are VFC controlled and

have high automation;

8. Negative pressure production condition gives a good production

environment;

9. High annual production capacity: ****0 thousand tons. Note: We

have prepared two sets of Ball Mill & Classifier production

lines in our factory to do any industrial testing!

Working Principle of Superfine Ball Mill &

Classifier Production Line:

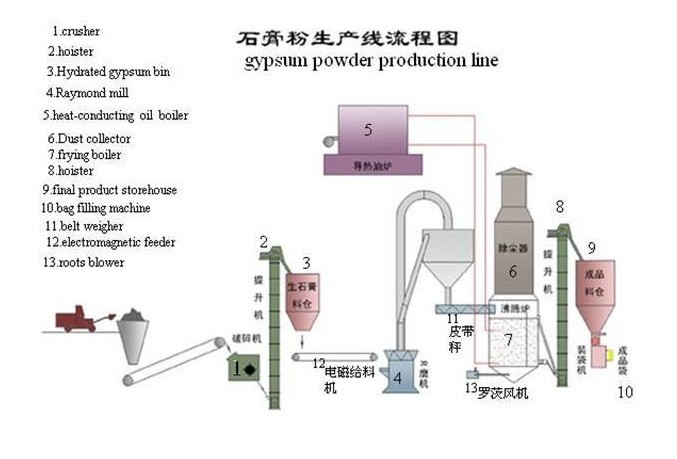

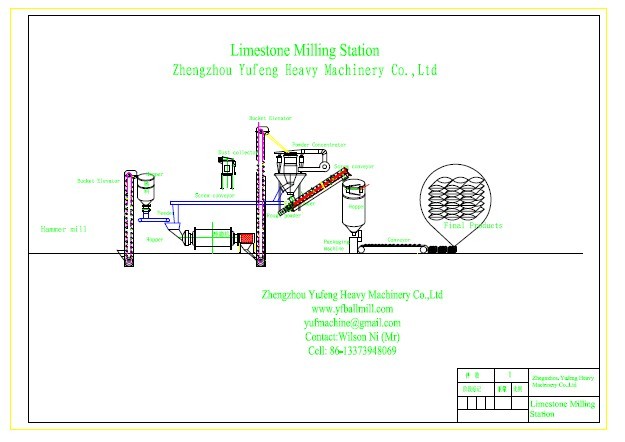

1. Material feeding: After the materials are roughly crushed,

they will be fed into the Ball Mill.

2. Impact grinding: when the milling chamber is rotating at high

speed, grinding medium and grind-need materials, which are also

rotating, will impact with each other; thus to achieve impact

grinding for materials;

3. Classification: after the materials are crushed, they will be

discharged into self-diffluent classifiers. And then the

relatively coarse and fine powders will be separated. Qualified

powders will be collected; and unqualified powders will be

re-crushed. Note: Cleaned gas will be discharged by induced draft

fans.

| Country: |

China |

| Model No: |

YUF

|

| FOB Price: |

(Negotiable)

Get Latest Price

|

| Place of Origin: |

- |

| Price for Minimum Order: |

- |

| Minimum Order Quantity: |

- |

| Packaging Detail: |

- |

| Delivery Time: |

- |

| Supplying Ability: |

- |

| Payment Type: |

- |

| Product Group : |

7.Superfine Powder Production Line

|