FOB Price

Get Latest Price|

100 Kilogram Minimum Order

Country:

Pakistan

Model No:

-

FOB Price:

Place of Origin:

-

Price for Minimum Order:

-

Minimum Order Quantity:

100 Kilogram

Packaging Detail:

20 and 40 kg plastic drums

Delivery Time:

10-15 days

Supplying Ability:

1 Ton per Day

Payment Type:

Western Union, L/C, T/T

Product Group :

Pakistan

Contact Person Mr. Syed Jawad

office No 51,Malir Cantt Karachi, Karachi, Sindh

SCOPE:

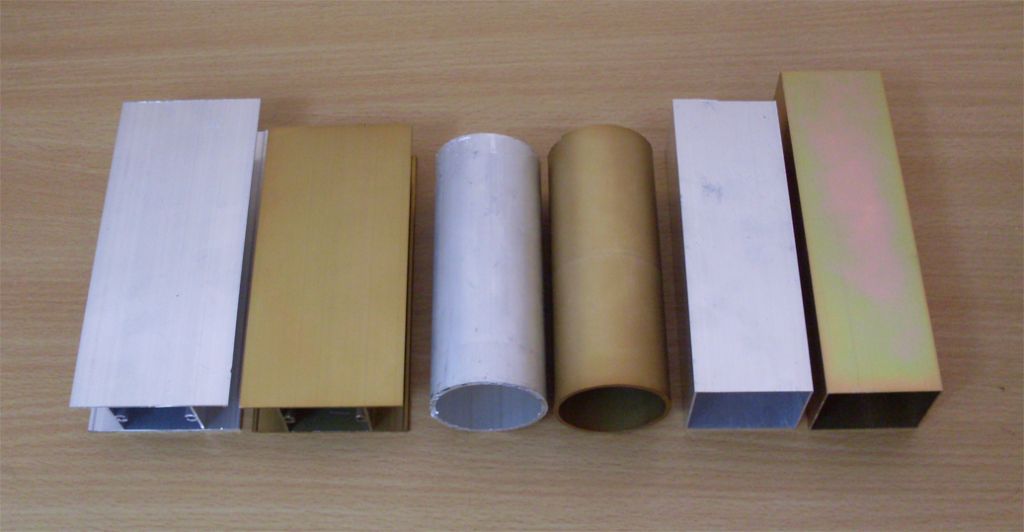

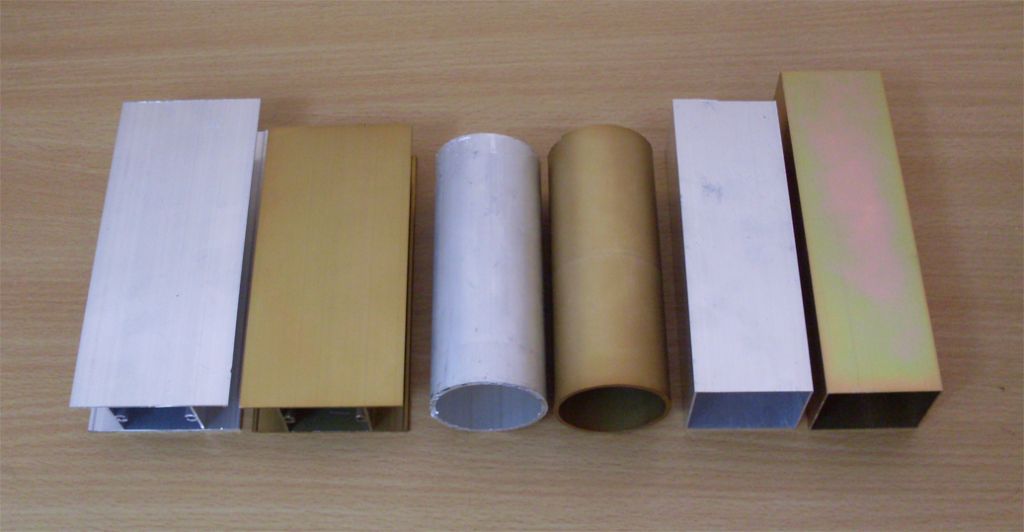

HAMBOND-A chemical is designed for the

treatment of aluminum, its alloys or zinc metal surface by spray or

immersion application. The treatment forms on the aluminum or zinc

surface a thin amorphous oxide trivalent chromate coating

iridescent to yellow brown in color depending on the alloy and

treatment time. This coating provides good corrosion resistance and

excellent paint adhesion with the base metal and it also provide

efficient corrosion resistance for unpainted surface as

well.

PRINCIPAL USE

It produces chromate coating on aluminum for

excellent paint adhesion and corrosion

resistance.

PROCESSING

TIME

2 *3 minute immersion at ambient

temperature

COVERAGE

**3 kgs/**0sqm

REQUIRED

CONCENTRATION

3 *5% with respect to the

volume

BENEFITS

| Country: | Pakistan |

| Model No: | - |

| FOB Price: | Get Latest Price |

| Place of Origin: | - |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | 100 Kilogram |

| Packaging Detail: | 20 and 40 kg plastic drums |

| Delivery Time: | 10-15 days |

| Supplying Ability: | 1 Ton per Day |

| Payment Type: | Western Union, L/C, T/T |

| Product Group : | Chromating Chemicals |