FOB Price

Get Latest Price|

- Minimum Order

Country:

China

Model No:

-

FOB Price:

Place of Origin:

-

Price for Minimum Order:

-

Minimum Order Quantity:

-

Packaging Detail:

-

Delivery Time:

-

Supplying Ability:

-

Payment Type:

L/C

Product Group :

China

Contact Person wei

Anqing, Anhui

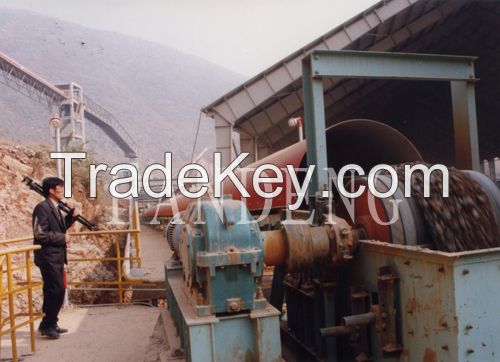

DTII, DTII (A) fixed

belt conveyor is a product of generalpurpose series, which is an

upgraded product improved on the basis of the two major TD*5 and DX

series, and can be divided into lightduty type, mediumduty type and

heavyduty type, compared with TD*5, it shows considerable

improvement whether in the aspects of material, process structure

and manufacturing accuracy, or in the aspects of conveying capacity

and reliability, etc. Therefore, its scope of adaptability is

wider, its conveying capacity and conveying distance are bigger and

longer, and it is widely used in such industries as of metallurgy,

mining, coal, harbor, power station, building materials, chemical

engineering, light industry, petroleum, grains, heating, etc. The

conveying system can be formed from a single equipment or multiple

equipments to convey materials, it can convey various kinds of bulk

materials and itemized goods with bulk density of 0.5~2.5t/m3, it

can also adopt combined conveying mode of convex curved segment,

concave curved segment or straightline segment. During the

selection, the design and calculation for type selection should be

made according to different terrains and different conditions with

a view to achieving expected effect. The temperature of conveyed

material should preferably be below *0°C, the operating ambient

temperature should be within *5°C~**0°C, and necessary protective

measures should be taken for working environment with special

requirements.

This series conveyor is differentiated as

follows through optimum design on the basis of TD*5 conveyor: The

type with head and tail frame added with triangular reinforcement;

The drive mode is added with head drive, intermediate drive and

multipoint drive from original single drive; The reducer is added

with ZSY, DCY and imported series (with multiple types) with

flexible arrangement pattern from original ZQ series; And the

structures such as various series holdback devices, YWZ5 series

brake, YOX series coupling, etc. are added, which ensure safe

operation; The roller is divided into lightduty type, mediumduty

type and heavyduty type, which adopts keyless expansion sleeve for

connection, with allwelded or case welded construction; Many

different specifications are added to the idler set under the

condition of same belt width so as to meet the requirements for

different loads and operating speeds; The takeup method is added

with head takeup, intermediate and tail movement weight takeup,

winch takeup, hydraulic takeup, etc. The rubber belts are added

with several varieties, such as nylon, polyester canvas and steel

cable core on the basis of original canvas so as to accommodate

requirements for different lump sizes and different belt

strength. DTII, DTII (A) fixed belt conveyor is a product of

generalpurpose series, which is an upgraded product improved on the

basis of the two major TD*5 and DX series, and can be divided into

lightduty type, mediumduty type and heavyduty type, compared with

TD*5, it shows considerable improvement whether in the aspects of

material, process structure and manufacturing accuracy, or in the

aspects of conveying capacity and reliability, etc. Therefore, its

scope of adaptability is wider, its conveying capacity and

conveying distance are bigger and longer, and it is widely used in

such industries as of metallurgy, mining, coal, harbor, power

station, building materials, chemical engineering, light industry,

petroleum, grains, heating, etc. The conveying system can be formed

from a single equipment or multiple equipments to convey materials,

it can convey various kinds of bulk materials and itemized goods

with bulk density of 0.5~2.5t/m3, it can also adopt combined

conveying mode of convex curved segment, concave curved segment or

straightline segment. During the selection, the design and

calculation for type selection should be made according to

different terrains and different conditions with a view to

achieving expected effect. The temperature of conveyed material

should preferably be below *0°C, the operating ambient temperature

should be within *5°C~**0°C, and necessary protective measures

should be taken for working environment with special

requirements.

This series conveyor is differentiated as

follows through optimum design on the basis of TD*5 conveyor: The

type with head and tail frame added with triangular reinforcement;

The drive mode is added with head drive, intermediate drive and

multipoint drive from original single drive; The reducer is added

with ZSY, DCY and imported series (with multiple types) with

flexible arrangement pattern from original ZQ series; And the

structures such as various series holdback devices, YWZ5 series

brake, YOX series coupling, etc. are added, which ensure safe

operation; The roller is divided into lightduty type, mediumduty

type and heavyduty type, which adopts keyless expansion sleeve for

connection, with allwelded or case welded construction; Many

different specifications are added to the idler set under the

condition of same belt width so as to meet the requirements for

different loads and operating speeds; The takeup method is added

with head takeup, intermediate and tail movement weight takeup,

winch takeup, hydraulic takeup, etc. The rubber belts are added

with several varieties, such as nylon, polyester canvas and steel

cable core on the basis of original canvas so as to accommodate

requirements for different lump sizes and different belt

strength.

| Country: | China |

| Model No: | - |

| FOB Price: | Get Latest Price |

| Place of Origin: | - |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | - |

| Packaging Detail: | - |

| Delivery Time: | - |

| Supplying Ability: | - |

| Payment Type: | L/C |

| Product Group : | Material transportation machinery |