Product Description

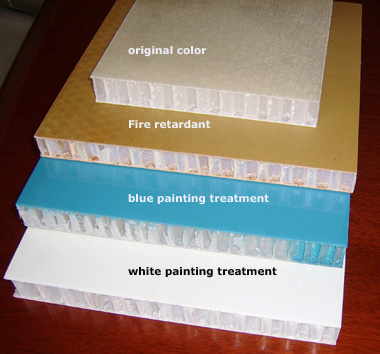

Fiberglass pre-immerged resin sheet (FRP ) as skin panel on

both sides, PP honeycomb as core. Resin adopted is Epoxy or

Phenolic .There are about *0% consumption in FRP skin ,so

composite panel is more lighter in weight meanwhile more

stiffness comparing with cold lamination,in later there are only

less than *0% fiberglass adoption in FRP skin.

The features of Polycore FRP PP honeycomb sandwich panel

are light weight, high stiffness, sound damping, fire-retardnat,

quakeproof, insulation, environmental friendly.

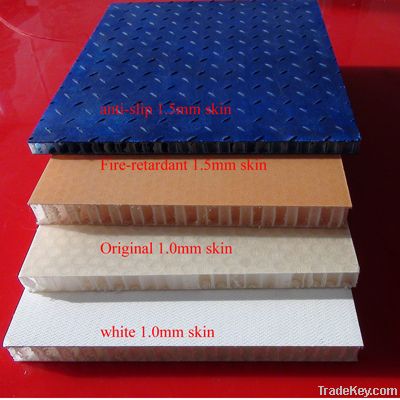

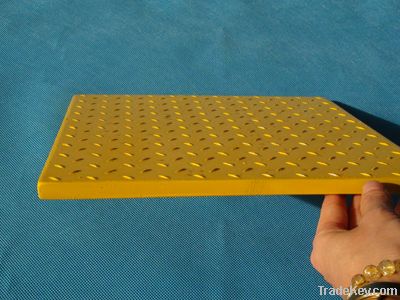

FRP plastic honeycomb sandwich panel is most popular light

weight , stiffness composite board in practice. The thinnest

fiberglass can be made is 0.3mm on both sides of PP honeycomb,

other thickness and weight can be made according to customer

special requirement. fiberglass surface panel strengthen PP

honeycomb strength in every physical parameter. Other surface panel

can be selected to make sandwich panel according to customer

demand.

PP honeycomb Sandwich board is widely applied in Marine as

structural material such as hull, deck, bulkhead, tank, canopies

and cases;

Sandwich board is applied in Tooling as fabricating tooling and

moulds;

Sandwich board is applied in truck as truck sides, fairing, guard

and floor hoods;

Sandwich board is applied in wind turbine act as blades, canopy

housing and rotor hoods;

Sandwich board is applied in sport as leisure, film set and

decorative market;

Sandwich board is applied in corrosion to prevent and repair of

metal and concrete surfaces;

Sandwich board is applied in chemical barrier to provide protection

for tanks, pits, pipes and grates.

| Country: |

China |

| Model No: |

frp-pp

|

| FOB Price: |

( Negotiable ) (Negotiable)

Get Latest Price

|

| Place of Origin: |

China |

| Price for Minimum Order: |

- |

| Minimum Order Quantity: |

50 Piece |

| Packaging Detail: |

pallet |

| Delivery Time: |

2 weeks |

| Supplying Ability: |

1000 Square Meter per Week |

| Payment Type: |

L/C, T/T |

| Product Group : |

structural material

|