Product Description

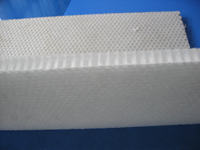

Polycore polypropylene (PP) honeycomb

reportedly provides greater strength-to-weight ratio than

traditional polyaramid or aluminum honeycombs. The cells of the

PP honeycomb are essentially circular rather than hexagonal and

are fused together rather than glued. The recyclable honeycomb

can be thermoformed and cut to shape easily has energy-absorbing

and sound- and vibration-damping properties, and is resistant to

fungus, rot, chemicals and moisture.

Honeycomb core cell

diameter from 8mm to *2mm,most commonly adopted is 8mm,*0mm,*2mm

can be made according to client request. Honeycomb core can be

directly apply into air purify and other fields without tissue on

both sides. Core cell wall thickness can be selected if clients

have special requirement. Core cell 8mm density is *8kgs/cubic

meter. Core cell *2mm density is *5kgs/cubic meter.

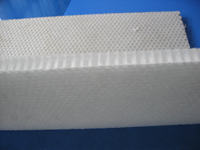

PP honeycomb sheet

laminated with polyester tissue on both sides. This allow

better bonding of the honeycomb to different surface

panel. In addition to the tissue, honeycomb can laminated

with a layer of PP film . The film under the tissue acts as a

barrier to prevent resin leaking into the core thus save resin

consumption in next assembly process Besides there is more

stiffness plastic sheet with more thicker tissue.

Honeycomb

sheets are used in the fabrication of lightweight structures.

The core material is typically 'sandwich' with plywood,

aluminium, fiberglass, steel, granite, paper and other solid

surface materials, etc. To attach the surface material to

the honeycomb sheet, a bonding adhesive can be used or the

materials can be laminated with polyester or epoxy systems. For

example,if select plywood as skin material,PP honeycomb as core

material,one kind of resin or glue which is familiar with wood at

same time its familiar with plastic material will be work to

laminate plywood with PP honeycomb. In a similar way,if select

fiberglass as skin material,PP honeycomb as core material,one

kind of resin which is familiar with fibergalss at same time

familiar with plastic material will workable to laminated

fiberglass with PP honeycomb.Now most of client select

fiberglass as skin material,epoxy or unsaturated resin as

adhesive to laminate on PP honeycomb sheet.The resultant honeycomb panel

results in one of the highest strength to light weight

available.

For example:

*0mm thickness PP honeycomb weight is only 2.**2.4kgs/square

meter but its compressive strength high to 2.0Mpa.

Polycore supply

dimension ***0****0mm,***0****0mm,***0****0mm, width within

***0mm,length within ***0mm. Thickness from 4mm to **0mm.Common

thickness in practice from 8mm to *0mm.

| Country: |

China |

| Model No: |

PP8t40f

|

| FOB Price: |

( Negotiable ) (Negotiable)

Get Latest Price

|

| Place of Origin: |

China |

| Price for Minimum Order: |

- |

| Minimum Order Quantity: |

100 Piece |

| Packaging Detail: |

carton |

| Delivery Time: |

2 weeks |

| Supplying Ability: |

10000 Square Meter per Week |

| Payment Type: |

L/C, T/T |

| Product Group : |

structural material

|