Product Description

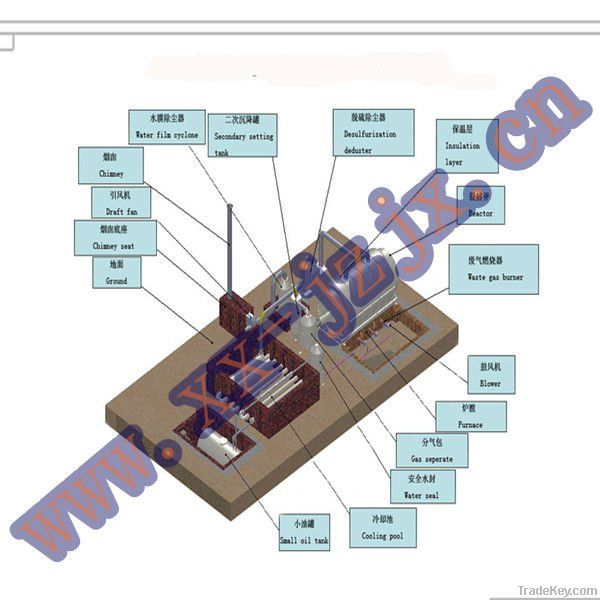

1. First, feed the raw material into the reactor, the raw

material includes waste plastic, waste rubber, waste tyres. You

can use the manpower and the belt conveyer to feed, if you use

the belt conveyer, it reduces the manpower and time, it's high

effective.

2.Under the reactor is the furnace, it is used

to heat the reactor. The fuel burns in it.When the fuel begins to

burn, the raw material begins to melt.At the same time, the fuel

produces smoke, and the smoke gets through the waste gas pipe

into the desulfurization deduster, it begins the first removing,

If the fuel is coal, it burns and produces the sulfur, when the

sulfur gets in, meets with the alcalescent water, they

neutralize, then removes the sulfur, and the dust in the smoke

gets down the water, and remove the dust .if not ,the smoke gets

into the water-film cyclone ,because of the function of the

centrifugal force, the water becomes vapor, and the dust gets

down the water. Through the two process ,the waste gas

becomes environment protective and energy conservation.At last

,the clean gas goes into the atmosphere.

3.When the temperature in the reactor is about

**0 centigrades, it produces the oil gas, it gets through the oil

pipe into the gas separate; it’s for the first time depositing.

And the oil will be clean, if not, it gets into the depositing

tank, the heavy oil gets down, the clean oil gets into the

cooling pool, and cools down.Through the cooling system , the oil

becomes liquid, then flows into the oil tank.

4.Some exhaust gas such as the CH4, it can't

be liquified at the normal temperature and pressure,so it goes

into the waste gas recycle system ,then to the furnace for

burning ,not only energy saving, but also environmental

protecting.After all the process ,there may be a

little flammable gas can not be used.For safety,you can fire

it in the waste gas combustion.

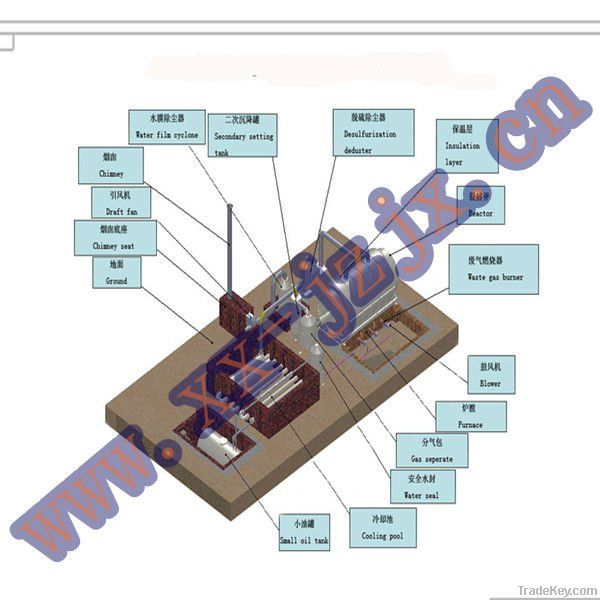

1. First, feed the raw material into the reactor, the raw

material includes waste plastic, waste rubber, waste tyres. You

can use the manpower and the belt conveyer to feed, if you use

the belt conveyer, it reduces the manpower and time, it's high

effective.

2.Under the reactor is the furnace, it is used

to heat the reactor. The fuel burns in it.When the fuel begins to

burn, the raw material begins to melt.At the same time, the fuel

produces smoke, and the smoke gets through the waste gas pipe

into the desulfurization deduster, it begins the first removing,

If the fuel is coal, it burns and produces the sulfur, when the

sulfur gets in, meets with the alcalescent water, they

neutralize, then removes the sulfur, and the dust in the smoke

gets down the water, and remove the dust .if not ,the smoke gets

into the water-film cyclone ,because of the function of the

centrifugal force, the water becomes vapor, and the dust gets

down the water. Through the two process ,the waste gas

becomes environment protective and energy conservation.At last

,the clean gas goes into the atmosphere.

3.When the temperature in the reactor is about

**0 centigrades, it produces the oil gas, it gets through the oil

pipe into the gas separate; it’s for the first time depositing.

And the oil will be clean, if not, it gets into the depositing

tank, the heavy oil gets down, the clean oil gets into the

cooling pool, and cools down.Through the cooling system , the oil

becomes liquid, then flows into the oil tank.

4.Some exhaust gas such as the CH4, it can't

be liquified at the normal temperature and pressure,so it goes

into the waste gas recycle system ,then to the furnace for

burning ,not only energy saving, but also environmental

protecting.After all the process ,there may be a

little flammable gas can not be used.For safety,you can fire

it in the waste gas combustion.

| Country: |

China |

| Model No: |

jzYT-10/8/5

|

| FOB Price: |

45000 ~ 52000 / Set (Negotiable)

Get Latest Price

|

| Place of Origin: |

henan,china |

| Price for Minimum Order: |

45000 per Set |

| Minimum Order Quantity: |

1 Set |

| Packaging Detail: |

Container &40feet FR to load tyre remelting machinery |

| Delivery Time: |

15~20working days after we receive 30%payment |

| Supplying Ability: |

20 Set per Month |

| Payment Type: |

L/C, T/T |

| Product Group : |

waste tyres pyrolysis plant

|