FOB Price

Get Latest Price|

- Minimum Order

Country:

China

Model No:

-

FOB Price:

Place of Origin:

-

Price for Minimum Order:

-

Minimum Order Quantity:

-

Packaging Detail:

-

Delivery Time:

-

Supplying Ability:

-

Payment Type:

-

Product Group :

-

Contact Person bo

Jinan, Shandong

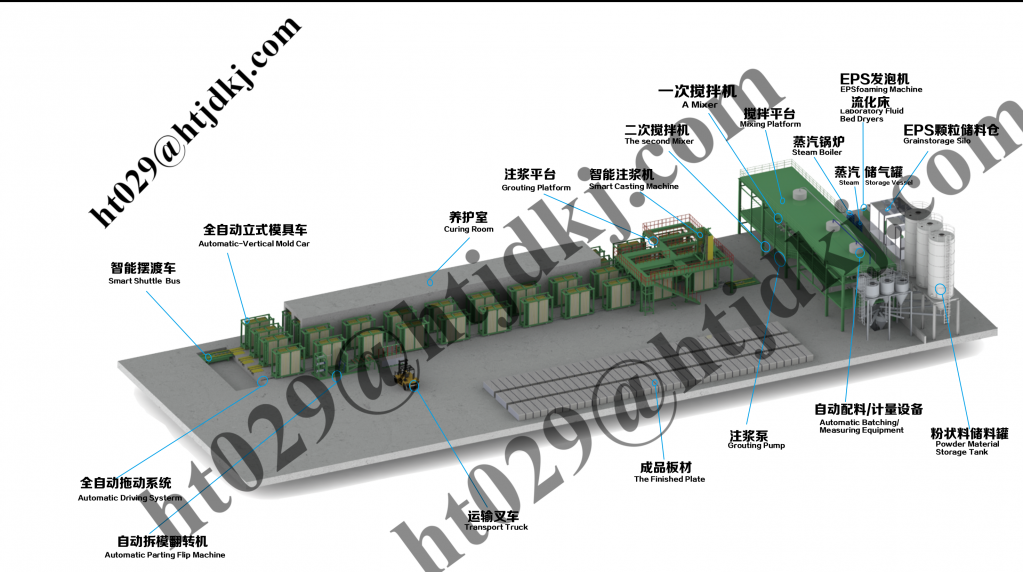

*2. HLLJ automatic polystyrene particle composite (EPS)

lightweight wallboard production line (Fully automatic EPS

composite lightweight wallboard production line)

Fully automatic EPS composite lightweight wallboard production line

with a high degree of automation, high tech content,high production

efficiency, high reliability and low price of equipment, low end

product cost, to adapt to China's national conditions, the

production of wall panels to meet the needs of the market

characteristics. It is company through years of technical

research,after market research and long term accumulation of

technology.combined with the most advanced production technology at

home and abroad, research and development of lightweight wall panel

automation production equipment.

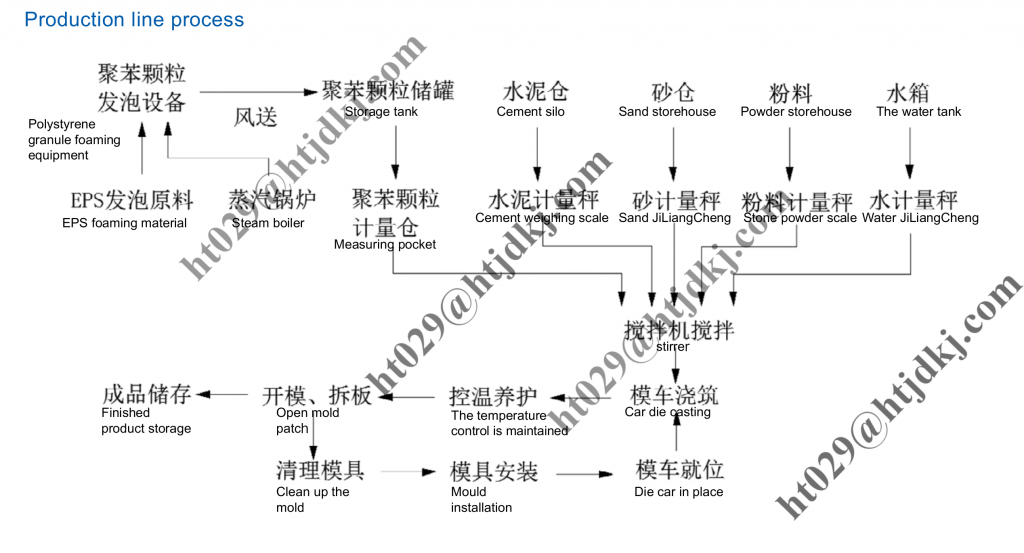

This production line feeding system measurement accuracy, high

degree of automation, stable performance;mixing system mixing

evenly, compact structure, beautiful appearance, smooth operation,

easy to operate; the use of automatic mold split machine work

effciency,reduce the production process of sheet metal damage;

pouring mold precision accuracy, tightness, easy installation, the

resulting sheet shape stable, no deformation, no cracking,mold

traction, ferry system safe and reliable, simple operation, save

space, the core technology in the domestic second to none.

The production line can produce EPS composite lightweight wall

panels and solid core board (no silicate cover) Main raw materials:

silicate cover, cement, fly ash, EPS particles or ceramsite,

perlite and other light aggregate, additives, water.

Plate specifications: height ********0mm,

thickness *0/*5/*0/**0/**0/**0/**0/**0, width **0mm.

Uses: inside the wall, the external walls,

kitchen and toilet wall, pipe wells, fre wells, fre staircase

partitions, floor boards, roof panels, integrated board room,

high-grade villas, assembly-style supporting wall panels.

Specifcation: GB / T*********9 JG / T*******5

Installation

Atlas: *0J****1

With high quality, high strength, multiple

environmental protection, thermal insulation, noise, water, fre,

hanging strong, rapid construction,reduce the cost of the wall and

so on.

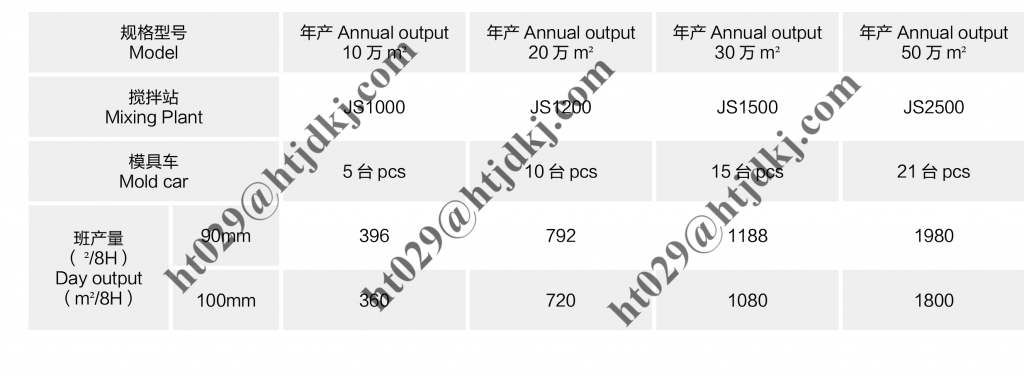

Model Annual output

**0,**0 m² Annual output

**0,**0 m² Annual output

**0,**0 m² Annual output

**0,**0 m²

Mixing Plant JS***0

JS***0 JS***0

JS***0

Mold car 5 pcs

*0 pcs *5 pcs

*1 pcs

Day output

(m²/8H) *0mm **6

**2 ***8 ***0

**0mm **0

**0 ***0 ***0

Mold machine

The raw materials used in the main engine manufacture are all made

of national standard profiles, and the whole machine parts

manufacturing is completed by CNC machining equipment.

The main engine we produce is high precision,

easy to operate, high production effciency, long service life, no

deformation and so on.

◆ Modular design, according to different production capacity, the

production line can reserve a station. Increasing the number of

molds when expanding production capacity can increase production in

a short period of time.

◆ Pour molding in the cavity, each surface is a mold forming

surface, the appearance is flat and beautiful.

◆ The mold car can produce up to *4 wall panels at one time.

◆ Steel mesh, short fiber or alkaliresistant glass fiber mesh can

be used as reinforcement material. The width is 0.6m, the

length is 2.4~3m, the thickness is *0mm, **0mm, **0mm, **0mm,

**0mm, **0mm. Other dimensions or special plates can be customized

according to requirements

Automatic grouting machine

Lift-down automatic grouting machine, automatic positioning,

automatic grouting, programmable control

Grouting transport system

The industrial hose pump is used as the grouting power. It only

needs 1 hose to connect. one people to complete the grouting

operation. The casting site is clean and efficient.

Advantages of industrial hose pumps:

Special non-sealing structure, free from any leakage and

pollution;

Using advanced technology, the roller does not need any

lubrication;

The fluid absorbed by the pump is only in contact with the hose,

and can convey various viscosity, density and corrosive

fluid materials;

Can transport solid particles, crystals, fiber materials and other

magazines liquid materials;

There will be no blockage and failure, self - absorption capacity

and self - cleaning capacity, can be forward - reverse suction.

Automatic mold removal system

A fully automatic plate dismantling machine can be installed in a

fixed position. It only needs 1 worker to operate normally.

The wall board of the whole vehicle can be taken out at the

same time within a few minutes,The board dismantling process

will not damage the wall board, high efficiency, low

operating costs.

Install process:

Project Example:

Lightweight wall

The wall is one of the main parts for building a building.

According to statistics, the building area of each square meter,

about 1.*2 *2.*2m cubed is wall panel, of which the inner wall is

about ****5%. With the development of building industrialization,

the developed countries began to change the wall materials as early

as since ***5, and the emergence of lightweight wallboard came into

being.

1.Product introduction :

It is divided into two types : inner wall panel and outer wall

panel. The thickness of the inner wall panel is *0, **0, and **0,

the width is betweeen ***0 to ***0. The thickness of outer wall

panel is **0, **0, **0, and **0.

2.Application field :

widely used in villas, buildings and industrial plants, warehouses,

cold storage original building and other works.

3.Product features:

light weight, high strength, good sound insulation, fire

prevention, waterproof, thermal insulation, good machining

performance, installation is simple, do not contain harmful

substances such as formaldehyde and asbestos, for the green

environmental protection and energy saving building materials.

4.Raw material:

stone powder (fly ash, coal gangue, construction waste),

inorganic environmental protection adhesive. Production process:

ingredients, agitation, extrusion molding, cutting , curing,

inspection of the factory.

Physical properties of lightweight the hollow core slab panel

Model specification ***0***0**0

The surface density *9.8kg/m^2

Bending damage load capacity 2.3 times of panel

self weight(***1N/m)

The anti-stamping performance Subjected to *0kg

standard sandbags, and the falling of 0.5m not cracked in *8 times,

and the cracks were not broken in *9 times.

A、Light: lightweight partition board production materials mainly

adopts light aggregate, weight is lighter, plus *6% of the time

hollow rate , bulk density in **0 ~ ***0 kg/m3, effectively reduce

the weight of the building, at the same time can reduce the basis

of economic investment, and convenient for construction and

transportation. The manual can carry and install, do not affect the

synchronous construction, the material transportation quantity is

small, the buildin and the building cost is reduced.

B、 Flexible space interval: can be the weight and the cost of the

according to the later decoration design requirements

C, Enlarge the use area: the owner has to increase the occupancy

rate.

D、 Heavy lifting load: single point hanging force is ***0 newtons.

Cupboard, condole ark, high water tank, plate type radiator can be

hang on it.

E、 sound insulation: can be insulate the decibel *6 and *2, sound

insulation and sound absorption of good building materials.

F、 Thermal insulation: the thermal conductivity of the lightweight

partition board is: 0.*2w /m.k is only 1/*0 of the

concrete (air dry state), which can greatly reduce the use

frequency of cold and warm air conditioning. 9cm thick wallboard

can be worth *4cm brick wall, *0cm gas block wall. The wall board

does not need the insulation material that can meet the national

standard requirement, provide comfortable living environment for

people.

G、 Fire prevention performance: light wall panel for inorganic

matter itself, not burning, not produce poisonous gas, is an ideal

freproof material, also provides the structure of certain fre

prevention function, 9 cm thick wall plate, for example, fre

prevention ability for 2 hours.

H、 the anti-seismic effect is good: elastic modulus is low, the

impact can absorb fast, the seismic level can reach level 8. I、

buried line tube is convenient for scientifc production technology

to make the product highly accurate, the joint is

accurate, and easy to process, can cut, dig the wire slot and so

on. Change the old brick wall to bury the line diffcult

situation.

J、 High strength: It is produced by screw extrusion, so the

strength is high, and the connecting part of the plate is connected

with a pull lock, so the overall load can reach or even exceed the

strength of ordinary brick masonry.

K、 convenient construction: the lightweight wall panel as a board,

with advanced scientifc installation way, so don't need to brace in

the construction, no post, no door lintel, without door window

frame installation of concrete bricks, solve the tedious process of

bricks in construction, saving the cost. Can be according to, can

be nailed, can be chisel, the construction is convenient for water,

conduit tube embedded and door window installation and node

processing.

L、 high labor effciency: factory prefabrication, site assembly,

fast construction speed, and greatly improve labor effciency.

M、 no need to paint the light: wall board because of its high

precision, it does not need to use a lot of cement mortar to paint,

so it can achieve the effciency of economy in raw materials, labor

cost and construction time.

N、 Cleaning on site:does not need to be cleaned, and the wet work

is avoided. The overall effect is good, and the

construction waste is produced in a small way, which can keep the

site clean and tidy.

O、 Conforming to the national policies and conforming to the trend

of the world development, lightweight wallboard is one of the

preferred components of construction assembly industrialization

| Country: | China |

| Model No: | - |

| FOB Price: | Get Latest Price |

| Place of Origin: | - |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | - |

| Packaging Detail: | - |

| Delivery Time: | - |

| Supplying Ability: | - |

| Payment Type: | - |

| Product Group : | - |