FOB Price

Get Latest Price|

- Minimum Order

Country:

China

Model No:

-

FOB Price:

Place of Origin:

-

Price for Minimum Order:

-

Minimum Order Quantity:

-

Packaging Detail:

-

Delivery Time:

-

Supplying Ability:

-

Payment Type:

-

Product Group :

-

Contact Person bo

Jinan, Shandong

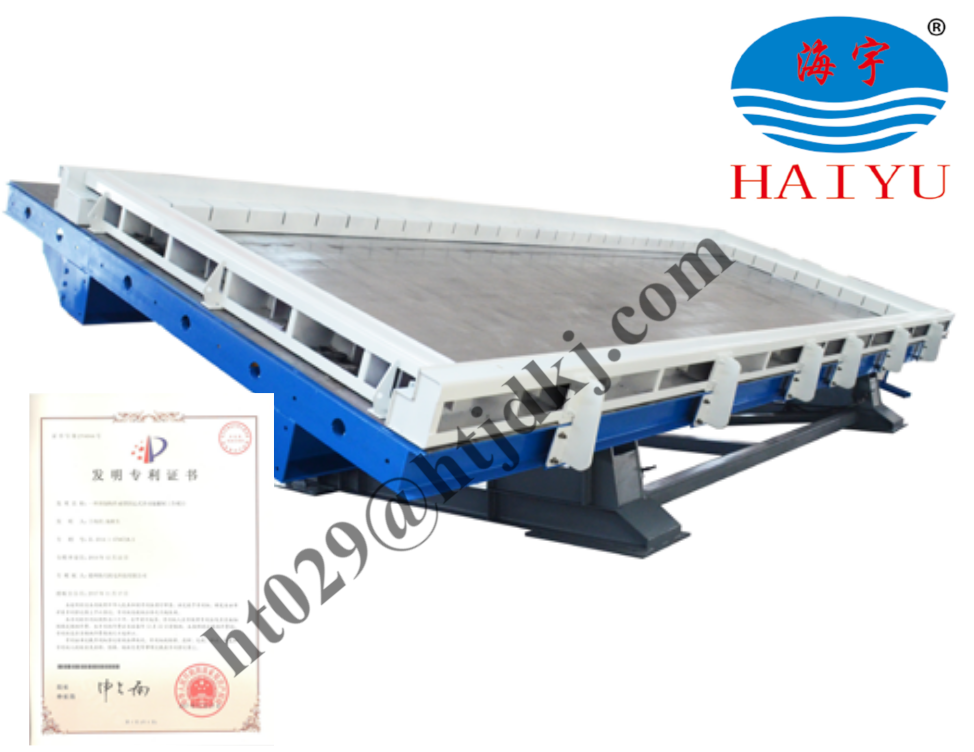

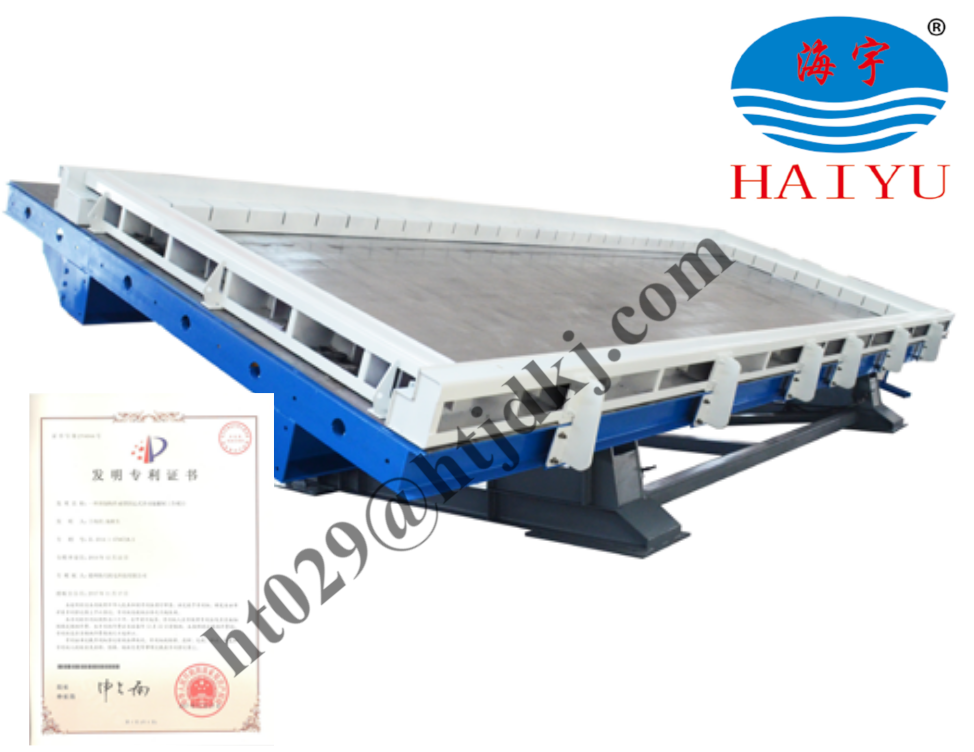

*4.HMT Multi-function Mold Production Line

The multi-functional tilting table production line is composed of

material mixing, concrete transportation, distribution machine,

multifunctional tilting table, and molds. The company employs a

team of Italian experts to elaborate a prefabricated production

model based on the Chinese assembly market. The table sets

integrate vibration, steaming, and tilting functions into one.

Technology advantages:

● Obtained national invention patent;

● The mature technology of this table in Italy was designed and

developed by Osvaldo D'ORSOGNA BUCCI (Osvaldo) design team with

more than *0 years of experience in R&D and manufacturing of

prefabricated concrete elements;

● Specifications: ***0mmX***0mm (can be customized according to

customer requirements);

● The die rack is welded with high-quality national standard

profiles. The top plate is made of high-quality material Q**5,

thickness ≥ *0mm, flatness ≤ 1.5mm/3m, and bearing capacity

**0kg/m2;

● Each table is equipped with an independent hydraulic side

vertical device, and the hydraulic system is equipped with a

lifting safety control system, which improves the operational

safety performance;

● The surface of the table is specially polished and the finish can

reach 3.2 microns, ensuring the delicate appearance of each

concrete element;

● The table comes with a vibration device. Each table has a number

of original pneumatic vibrators imported from Italy. The speed is

up to ****0r/min, and the UHF vibration ensures each

element is dense;

● There is a finned heating tube below the die table and steam

heating is used for heating to shorten the production cycle and

increase the production efficiency;

● Multiple die sets can be assembled and connected, combined into

any length of production die sets, and tensioning pedestals at both

ends can be prestressed components;

● Side angle ~*0° ;

● Compared with existing domestic water production lines, this

model line production line can save about ***0 degrees of electric

energy per day. And maintenance costs are extremely low;

● This model production line can also be used as a "nomadic

production line". The production line is easy to install and debug.

It can be transported to the production site near the construction

site to reduce the transportation cost of components and save

transportation time.

*5.HBM Large-scale battery mold wall panel production line

This production line is the subject of the *3th Five-Year national

key R&D special project Key technology and equipment for

industrial production of precast concrete components undertaken by

our company. The large-scale vertical mold wallboard production

line is designed by our Italian team of experts for large-scale

planar components. The thickness of the *****0mm solid sandwich

wall panel is smooth on both sides of the wallboard. The system is

flexible and can produce components of various thicknesses, widths

and heights, which can meet the different needs of different

customers, and can also customize the production plan according to

the needs of customers.

*6.

HYL Precast Beam Production Line

Precast Concrete Beam Framework designed by our Italy technical

team. It is a size self-adjusting steel mould. It is self-sealing

and self-vibration (by drop-in type or automatic type). It can

produce t beam, double t beam, L beam, I beam, Y beam and other

kinds of precast element. Solution can be made upon customer

request and meet your requirement well

*7.

HLT Precast Stair Production Line

Our company can produce all kinds of precast concrete stair moulds

according to the different needs of customers.

● Vertical stair mould

Advantages: light weight, simple debugging, quick mold-cutting,

and

sealing effect to ensure dripping. The artificial calendering

surface is small, and the surface area of the component is

extremely low, which is suitable for mass production of clean water

stairs.

● Adjustable stair mould

Advantages: Under the premise of the same step width and thickness

of the ladder, the step height, the number of steps and the length

of the upper and lower rest platforms can be adjusted, and the

pneumatic vibrator is provided. One set of molds can produce a

variety of dimensional stair members.

● At the same time, we can customize various "horizontal staircase

moulds, one-piece double-stair moulds, interior wall moulds,

exterior wall moulds, laminated board moulds, balcony moulds, bay

window moulds and other various shaped moulds.

*8.

HGL Precast Pipe gallery Production Line

Pipe gallery features: The quick locking device is made of special

steel, open and close mold is simple, easy to adjust, strong

service life reduces labor intensity,saving special tools.

Mold opening and closing using hydraulic and mechanical

transmission in two ways,at the same time with fastening and the

overall opening and closing side mode and other functions, can

achieve the mold of the opening more quickly, strong service life

reduces labor intensity, save the labor cost.

Die configurable Italy imported pneumatic vibrator attached high

frequency or high frequency attached electric vibrator, can enhance

the compactness of concrete products, reduce the occurrence of

bubbles, the surface of the product is more beautiful, more reduces

the labor intensity, improve production efficiency

| Country: | China |

| Model No: | - |

| FOB Price: | Get Latest Price |

| Place of Origin: | - |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | - |

| Packaging Detail: | - |

| Delivery Time: | - |

| Supplying Ability: | - |

| Payment Type: | - |

| Product Group : | - |