Product Description

Pure Acrylate Sports Coating for

Hard Court Surface

DESCRIPTION:

Nalstane Pure Acrylate Sport Hard

Court Surface Systems provide a highly durable, all weather

sporting surface with excellent abrasion resistance and uniform

texture.

Manufactured from selected premium **0% acrylic resins, light

stable oxide pigments and proven reinforcing powders assure

maximum U.V. resistance to provide years of non-fade life.

The specialized resins used in the production of Nalstane provide

excellent scuff resistance in both wet and dry conditions.

The Nalstane Pure Acrylate Sport Hard Court Surface Systems for

asphalt bases comprises two (2) applications of Filler Coat and

at least one (1) application of Nalstane Top Coat.

Ball bounce on Nalstane PA is completely true and ball speed can

be varied by the application technique of the qualified

contractor.

ADVANTAGES:

Early water resistance. Dries

rapidly. Excellent adhesion. Excellent scuff resistance (in wet

and dry). Provides positive traction. Is easily cleaned. Remains

flexible. Provides true ball bounce and controlled ball

speed.

TYPICAL USES:

Tennis Courts, Basketball Courts,

Outdoor Play Areas, Volleyball Courts, Multi-purpose Sport

Courts.

SURFACE PREPARATION:

NEW ASPHALT SURFACES - A tight, uniform and even surface is required

to avoid the need for additional applications of Filler Coat. New

asphalt surfaces shall be allowed to cure for a minimum of *0

days before the application of the Nalstane System. The surface

finish shall be thoroughly cleaned to remove all loose dirt,

dust, oil, grease, leaves and other debris. The surface shall be

flooded with water to check for low areas. Minor depressions up

to 3mm may be leveled using undiluted Filler Coat applied by

steel trowel/squeegee or a combination of both. Deeper

depressions and minor surface cracks shall be filled with

Nalstane M***0 blending with concrete.

PREVIOUSLY COATED ASPHALT

SURFACES - Surface

preparation requirements are similar to those stated above for

new asphalt. The surface Shall be thoroughly cleaned and leveled.

Existing cracks shall be cleaned and filled with filler coat

Nalstane M***0. Existing line markings applied using an oil-based

paint shall be removed.

APPLICATION:

Do not use Nalstane PA system when

temperatures are either below 5°C or above *5°C, or when rain is

imminent. Sound surfaces require the use of two (2) coats of

Filler Coat and two (2) coat of Nalstane Top Coat. Areas of

excessive porosity should receive an additional coat of undiluted

Filler Coat applied by squeegee or trowel. In general, unless a

slower playing field for tennis is required, the first coat is to

be applied in a perpendicular (length wise) direction to the

playing net. The second coat is applied parallel with the playing

net with the finish coat perpendicular (length wise). To create a

slower playing field the reverse procedure is applicable.

BASE COATS – Mix primier A and B by ratio 1:1, stirring

4mintes and then Dilute it with water by ratio of 1 parts to 3

part of clean water and rolling onto concrete substrate. This

base coats is not necessary for asphalt substrate.

SECOND COAT (OR FILLER COAT)

- Dilute Filler Coat Nalstane M***0

in the ratio of 4 parts filler coat to 1 part sand. Stir the

mixture thoroughly before and during the application procedure to

provide a homogenous blend and avoid settlement. Pour the mixture

in 'wind rows' over the surface and spread evenly with a wide

flexible rubber squeegee, generally **0mm to **0mm in width.

Level off with a second squeegee. Note: In situations where the

asphalt base is unusually porous and additional filling is

required, it may be necessary to apply additional coats of

Nalstane M***0 neat without dilution. Any subsequent squeegee

lines must be rubbed smooth prior to the application of the final

Filler Coat.

TOP COAT - It is important that all ridges are leveled

off prior to the application of the finish coat and that the

finish coat is true with an even texture. Mix the Nalstane

Surface coating in the ratio of 4:1 with fine selected sands.

Pour the mixture in 'wind rows' over the surface and spread

evenly with a wide flexible rubber squeegee, level off with a

wide firm bristle broom before coating starts to dry. Apply a

minimum of 2 coat, length wise of the court.

COVERAGE: (BASED ON UNDILUTED

MATERIAL)

Coverage will depend upon the

texture of the base surface to which the Nalstane M***0 Filler

Coat is applied.

|

Nalstane M***0

|

|

|

1st coat:

|

**3 sqm per litre

|

|

2nd coat:

|

**4 sqm per litre

|

|

Nalstane Surface

Coating

|

**4 sqm per litre

|

DRYING TIMES:

In general the first filler coat

application will take longer to dry because of the extra

thickness of the product due to voids.

Allow approx. **1.5 hours at *5ºC. Additional coats average 0.5 -

1 hour at *5ºC.

Allow a minimum of 1 hour, depending on temperature, between

coats.

There is no maximum drying time limit between re-coats.

Playing time is generally *4 hours after completion, dependant on

good drying conditions.

Full hardness and abrasion resistance will take 4 *5 days under

good drying conditions.

LINE MARKING:

Apply Line***0 line paint by brush,

roller or spray. Colours available are white and yellow. Apply in

two (2) coats by brush or roller or one (1) coat by an

appropriate spraying unit to achieve a total coverage of

approximately *0 lineal metres per litre for *0mm wide

lines.

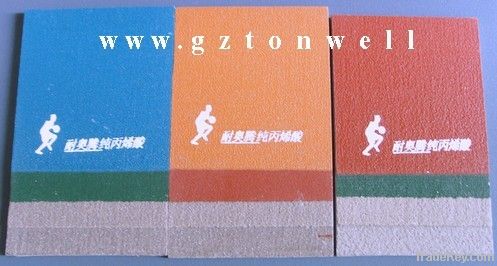

COLOURRANGE:

Nalstane is available in nine (9)

standard weather resistant colours. Special colours are available

on request. Deep Green, Forest Green, Light Sage, Terracotta,

Light Terracotta, Mid Tan, Mid Blue, Blue Grey, Fawn.

PRECAUTION:

Store in a cool place, never in the

hot sun, keep material from freezing. Clean all equipment with

water, immediately after use. Do not allow Nalstane PA coating to

drip on adjacent surfaces. Immediately remove drips with water as

dried product is difficult to remove and will create a blemish on

the finished surface.

LIMITATIONS:

Although Nalstane PA coating has

excellent early water resistance, do not apply when rain is

imminent or temperatures are below 5°C or above

*5°C.

| Country: |

China |

| Model No: |

PA-M200

|

| FOB Price: |

(Negotiable)

Get Latest Price

|

| Place of Origin: |

- |

| Price for Minimum Order: |

- |

| Minimum Order Quantity: |

100000 Square Meter |

| Packaging Detail: |

Acrylic acid lacquer: 5gallom/drum 55galon/drum |

| Delivery Time: |

7-10days after receipt of payment |

| Supplying Ability: |

- |

| Payment Type: |

T/T, L/C, Western Union, Other |

| Product Group : |

- |