FOB Price

Get Latest Price( Negotiable )

|1 Set Minimum Order

Country:

China

Model No:

HZS-50, HZS-75, HZS-100, HZS-150, HZS-2

FOB Price:

( Negotiable ) Get Latest Price

Place of Origin:

quanzhou,fujian,china

Price for Minimum Order:

-

Minimum Order Quantity:

1 Set

Packaging Detail:

containers

Delivery Time:

10-25days

Supplying Ability:

1000 Set per Month

Payment Type:

L/C, T/T

Product Group :

Contact Person Mr. kyle

#151-1207,xinjing tianhu olaza, Quanzhou, Fujian

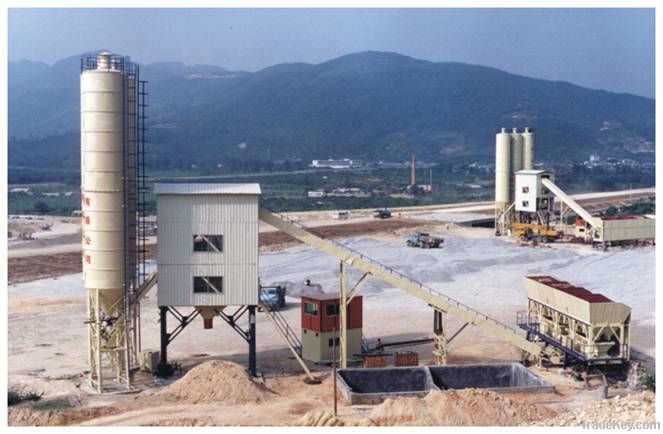

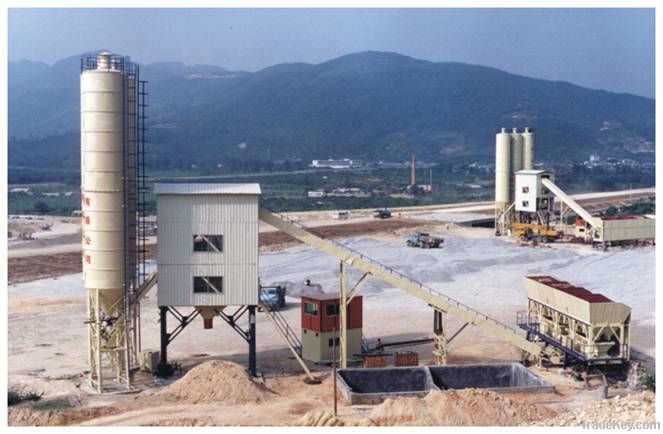

HZS mobile concrete batching plant, based on several new foreign

technologies, integrates years' experience of making concrete

mixing plant. The plant consisting of four separated modular

compact structures is easy to install; the mixer is twin-shaft

forced type with high productivity, and it can mix quickly and

evenly. Adopting advanced industrial computer to control, the plan

is of easy operating and highly automation. The product applies to

projects of highway, bridge, port and hydropower station which

requires large quantity of concrete.

Features:

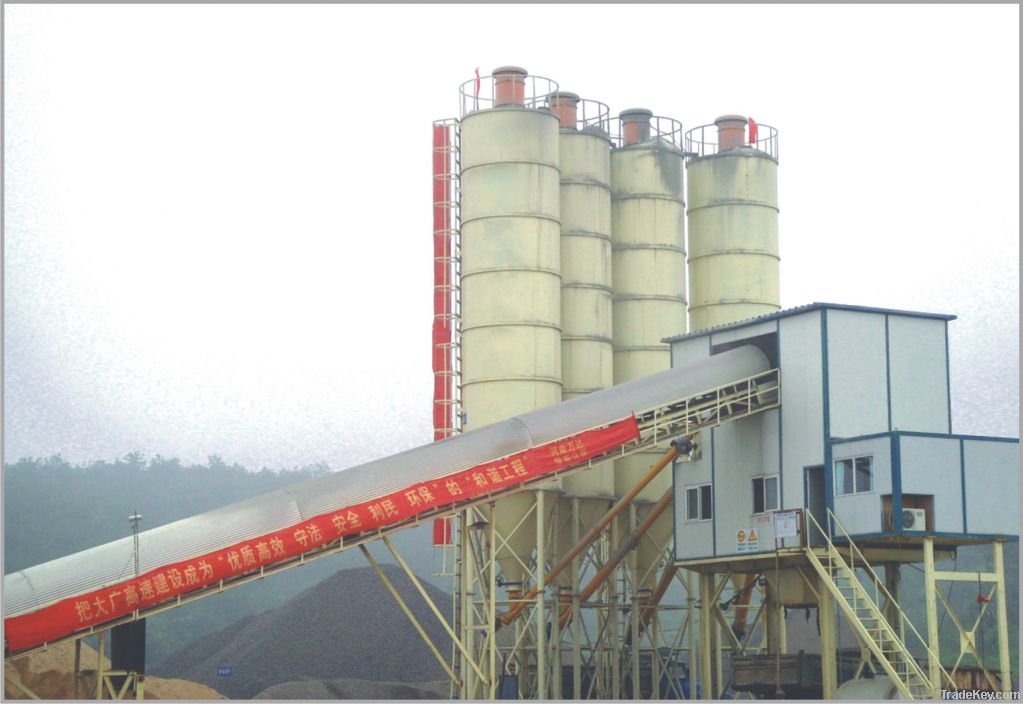

1. Stability and Durability: apply the most advanced technologies

around the world;

2. Reliability: *0 years of experiences in manufacturing concrete

mixing plants;

3. Stationary modular structure, fast and easy installation;

4. Horizontal Twin-Shaft Compulsory Mixer: excellent mixing

performance with high efficiency and high productivity;

5. Excellent environmental protection, dust collection system and

anti-noise design.

Excellent Mixing Performance

1. Horizontal twin-shaft compulsory mixer has the strong mixing

ability with uniform mixing and high production output. The

admixtures are widely mixed by the shafts, and reach the best

proportional ratio of uniform;

2. The mixing shafts adopt anti-binding technology to prevent the

cement from binding on the shafts;

3. Mixing paddles, arms and blades are made of special high

chromium and high manganese alloy materials. The wear resistance of

the mixing paddles saves time and cost to replace, and at the same

time, improves the machines durability and reliability;

4.The greasing system, which is controlled by central control

system, lubricates the greasing points at the fixed position, fixed

time and fixed quantity;

5. Decelerating system uses high-speed, synchronized, and closed

planetary decelerators.

6. The opening of discharge gate can be adjusted by hydraulic

system as per specific requirements.

Control System

1. The control system of double computers with double controls

consists of two industrial computers, one is production control

computer and the other is production management computer. The

control system has the following functions:

A. Automatic and manual control, easy operation;

B. Dynamic display of the production process, and monitoring in

real time;

C. Saving of the data of production perimeters in the computer,

printing of the daily, monthly, and yearly statistic reports of

production;

D. Weighing accuracy: automatic re-feeding if there is shortage of

weight, warning if there is overweight;

E. The operators with the assistance of safety monitoring system

will know and monitor the running situations of the mixing plant in

the control room.

2. The management computer is a backup computer for the whole

electric control system. When the control computer is out of order,

the management computer can be changed into the control computer to

control production.

3. Long-distance trouble shooting by internet and teleservice,

which greatly improves the users' ability to trouble shoot the

system.

4. The control room which is made of colorful shaped steel plates

is capacious, anti-noise and heat insulated. It guarantees the

working temperature of the electrical components, also improves the

working comfort.

| HZS*0 | HZS*5 | HZS**0 | ||

| Capacity(m3/h) | *0 | *5 | **0 | |

| Model | JS***0B | JS***0B | JS***0B | |

| Mixer | Power (kw) | 2**2 | 2**0 | 2**7 |

| Output | 1m3 | 1.5m3 | 2m3 | |

| AG Size | ||||

| Batcher | Hopper Size | 3x*3 | 3x*3 | 3x*3 |

| Hopper No. | 3 | 3 | 3 | |

| Conveyor | tph | **0 | **0 | **0 |

| AG | ***0±2% | ***0±2% | ***0±2% | |

| Accuracy | Cement | **0±1% | **0±1% | ***0±1% |

| Filler | **0±1% | **0±1% | **0±1% | |

| Water | **0±1% | **0±1% | **0±1% | |

| Additive | *0±1% | *0±1% | *0±1% | |

| Total Power (kw) | *2 | **8 | **7 | |

| Discharge Height (m) | 3.8 | 3.8 | 3.8 | |

| HZS**0 | HZS**0 | ||

| Capacity (m3/h) | **0 | **0 | |

| Model | JS***0B | JS***0B | |

| Power (kw) | 2x*5 | 2x*5 | |

| Mixer | Output | 3m3 | 4m3 |

| AG Size | |||

| Batcher | Hopper Size | 4**0 | 4**0 |

| Hopper No. | 4 | 4 | |

| Conveyor | tph | **0 | **0 |

| AG | ***0±2% | ***0±2% | |

| Cement | ***0±1% | ***0±1% | |

| Accuracy | Filler | **0±1% | **0±1% |

| Water | |||

| Country: | China |

| Model No: | HZS-50, HZS-75, HZS-100, HZS-150, HZS-2 |

| FOB Price: | ( Negotiable ) Get Latest Price |

| Place of Origin: | quanzhou,fujian,china |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | 1 Set |

| Packaging Detail: | containers |

| Delivery Time: | 10-25days |

| Supplying Ability: | 1000 Set per Month |

| Payment Type: | L/C, T/T |

| Product Group : | Modular Concrete Batching Plant |