FOB Price

Get Latest Price( Negotiable )

|1 Piece Minimum Order

Country:

China

Model No:

-

FOB Price:

( Negotiable ) Get Latest Price

Place of Origin:

China

Price for Minimum Order:

-

Minimum Order Quantity:

1 Piece

Packaging Detail:

Wood or Iron frame with plastic outside

Delivery Time:

30-60 days after PO confirm

Supplying Ability:

2000 Piece per Year

Payment Type:

T/T, L/C

Product Group :

Contact Person Levi

Jinan, Shandong

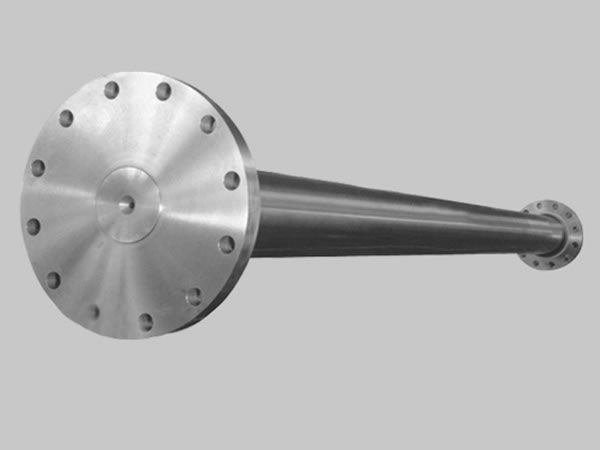

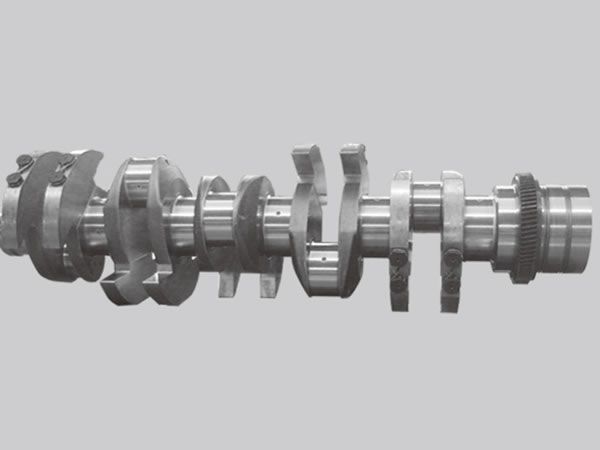

Forged Structural Parts for

ship

The large forgings for shipbuilding TongYu provides can be divided

into 2types: strcutual parts of ship (rubber stock, rubber pin,)

and shaft forgings( intermediate shaft, propeller shaft). The first

type mainly calls for high welding, but little carbon equivalent

requirement for steels.

Forging for ships feature large size

and heavy weight. Its performance requirements, especially property

diffirence between both ends of the boats is extremely harsh, Boats

opretaing in ice-filled require additional resistance to

low-temperature impact.

In the whole production lines of

smelting ,forging, heat treatment, flaw detection, and mechanical

processing ,TongYu has set strict quality control systerm, The

forging for shipbuilding made by TongYu comply with the

classification societies of each country. We have now been

certified by CCS ,ABS, BV, DNV, GL, LR, NK, KR, and

RINA.

TongYu is now one of major

manufacturer of large casting and forgings in China .We provide all

kinds of free forgings used for thermal power,hydroelectirc, and

shipbuilding industires

Clients are required to offer their

drawings and technical requirement, Which will transferred to

technical department(heat treatment center, large forgings research

center, mechanical research center, and welding department, etc,)

for confirmaion and accounting, Then we will offer you the

quotation, The ordered products will be put into production as soon

as possible after clients have placed an order. For any

problems rasied in the product line ,We will contact and disscuss

with our clients directly.

Common Materials

Carbon steel Carbon manganess

steel and alloy steel prescribed by classification societies, like

*0Mn *0Mn *5Mn *0Mn *5CrMo *2CrMo and *5Cr2Ni4MoV.

Manufacturing process

Smelting-forging-Heat treatment-Roughing-Quenching &

Tempering-Machining-Packaging.

(parts of forgings well-done

after tempering)

Quality control

| Country: | China |

| Model No: | - |

| FOB Price: | ( Negotiable ) Get Latest Price |

| Place of Origin: | China |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | 1 Piece |

| Packaging Detail: | Wood or Iron frame with plastic outside |

| Delivery Time: | 30-60 days after PO confirm |

| Supplying Ability: | 2000 Piece per Year |

| Payment Type: | T/T, L/C |

| Product Group : | Forgings |