FOB Price

Get Latest Price( Negotiable )

|1 Set Minimum Order

Country:

China

Model No:

002

FOB Price:

( Negotiable ) Get Latest Price

Place of Origin:

china shanghai

Price for Minimum Order:

-

Minimum Order Quantity:

1 Set

Packaging Detail:

wooden package

Delivery Time:

45 days after payment

Supplying Ability:

20 Set per Month

Payment Type:

L/C, Western Union, Money Gram

Product Group :

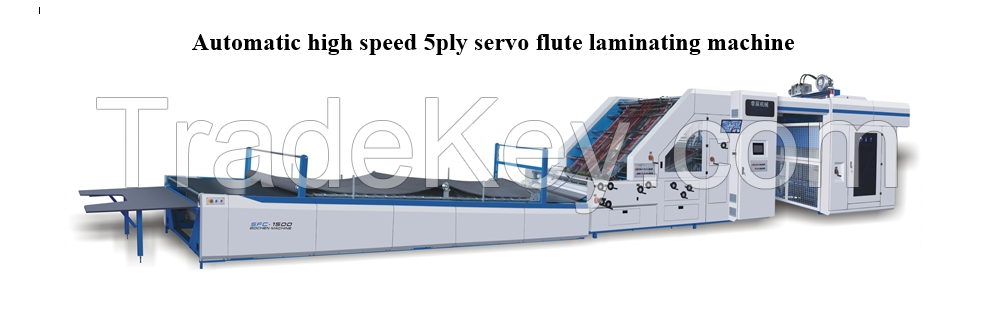

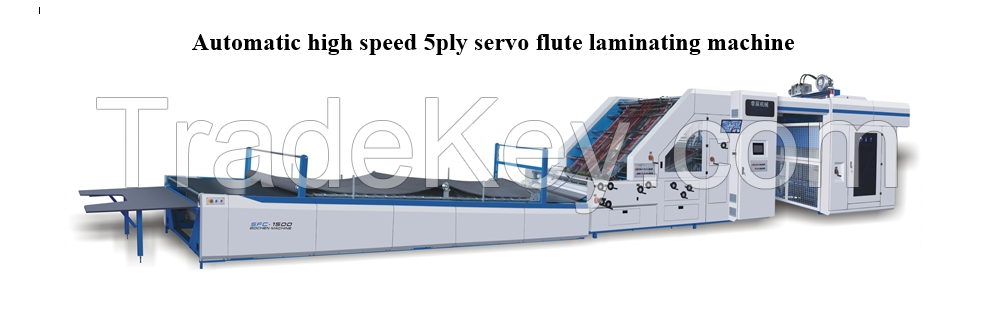

Automatic high speed 5ply servo

flute laminating machine is a new generation of high-speed

laminating machine developed by our company. It can laminating

three sheets of cardboard at once, and can produce three-layer,

four layer, five layer, seven layer, and nine layer boards to

increase material strength and thickness. The bottom paper adopts a

lead edge feeding structure for stable paper feeding, and the servo

tracking and correction principle of the top paper. Can achieve a

maximum laminating speed of **0 meters/minute. High speed,

efficiency, and precision are your ideal

choices.

Performance

characteristics

1.This machine can

laminatecombination of two corrugated boards

and any type oftop sheettogether.It

can produce two -layer board (cardboard+ cardboard), 3ply,4ply,

5ply, 7plyand other

products.

2. Laminating type: corrugated +

corrugated + cardboard, corrugated + corrugated, corrugated +

cardboard, cardboard + cardboard, cardboard + gray board +

cardboard, etc.

3. Bottom paper feeding structure

adopts a lead edge feeding, an extended and widened belt with large

suction to ensure stable bottom paper and cardboard feeding without

damaging the cardboard.

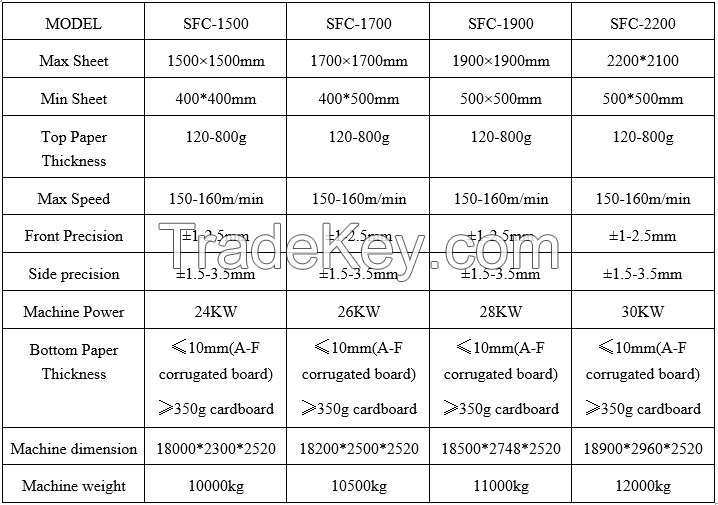

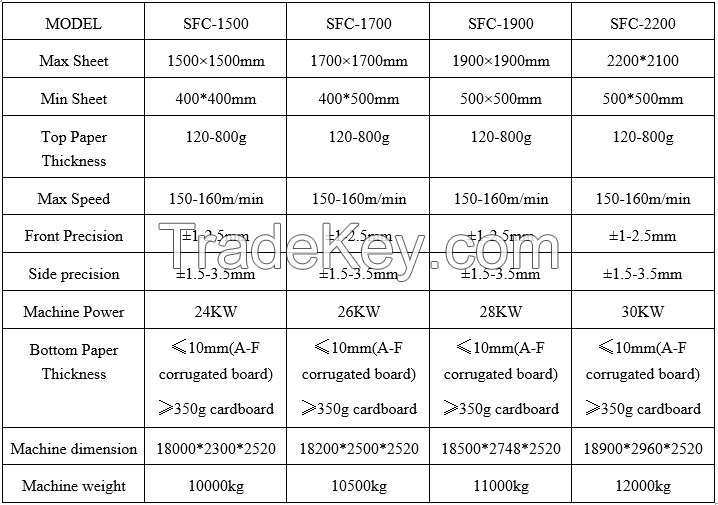

| MODEL | SFC-***0 | SFC*1*00 | SFC****0 | SFC****0 |

| Max Sheet | ***0×***0mm | ***0×***0mm | 19*0×19*0mm | ***0****0 |

| Min Sheet | **0***0mm | **0***0mm | 5*0×5*0mm | **0***0mm |

| Top Paper Thickness | ******0g | ******0g | ******0g | ******0g |

| Max Speed | **0***0m/min | **0***0m/min | **0***0m/min | **0***0m/min |

| Front Precision | ±1*2.5mm | ±1*2.5mm | ±1*2.5mm | ±1*2.5mm |

| Side precision | ±1.**3.5mm | ±1.**3.5mm | ±1.**3.5mm | ±1.**3.5mm |

| Machine Power | 24KW | 26KW | 28KW | *0KW |

| Bottom Paper Thickness |

≤*0mm(A-F corrugated

board) ≥350g cardboard |

≤*0mm(A-F corrugated

board) ≥350g cardboard |

≤*0mm(A-F corrugated

board) ≥350g cardboard |

≤*0mm(A-F corrugated

board) ≥350g cardboard |

| Machine dimension | ****0****0****0 | ****0****0****0 | ****0****8****0 | ****0****0****0 |

| Machine weight | ****0kg | ****0kg | ****0kg | ****0kg |

| Country: | China |

| Model No: | 002 |

| FOB Price: | ( Negotiable ) Get Latest Price |

| Place of Origin: | china shanghai |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | 1 Set |

| Packaging Detail: | wooden package |

| Delivery Time: | 45 days after payment |

| Supplying Ability: | 20 Set per Month |

| Payment Type: | L/C, Western Union, Money Gram |

| Product Group : | litho laminator |