FOB Price

Get Latest Price|

- Minimum Order

Country:

China

Model No:

-

FOB Price:

Place of Origin:

-

Price for Minimum Order:

-

Minimum Order Quantity:

-

Packaging Detail:

-

Delivery Time:

-

Supplying Ability:

-

Payment Type:

-

Product Group :

Contact Person lang

Suzhou, Jiangsu

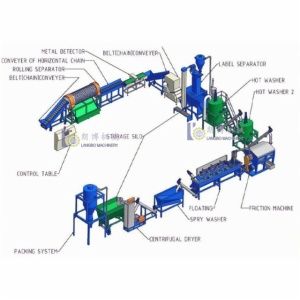

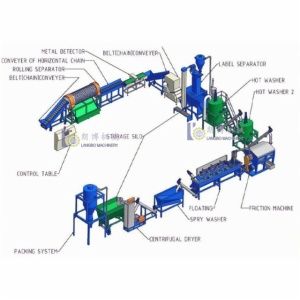

COMPONENTS AND FEATURES:

The complete recycling production for wasted PET includes of two

parts which the first part is crushing, washing and drying

production line with the final products is clean PET flakes and

the second part is pelletizing extrusion for clean flake with its

final products is PET pellet.

1.The processing procedure of the complete washing line for PET

consists of sorting - label removing – crushing - floating washer

with cold water - agitating washer with hot water- floating

washer with cold water - centrifugal drying - label separating

again–collection.

2,Wasted

PET can be crushed, washed, dried and collected into silo with

clean PET flakes.

,3 High efficiency and performance.

4. Less power consumption and operator attendance.

APPLICATIONS:

5. Applicable material: PET, ABS, PC, etc..

6. Materials shape: bottles, scraps, etc..

PRODUCTION CAPACITY:

7. The production capacity can be **0kg/hr, **0kg/hr, ***0kg/hr,

***0kg/hr and ***0kg/hr.

NOTE:

8. Depending on material shape, some units involved in complete

line will be changed and available.

| Country: | China |

| Model No: | - |

| FOB Price: | Get Latest Price |

| Place of Origin: | - |

| Price for Minimum Order: | - |

| Minimum Order Quantity: | - |

| Packaging Detail: | - |

| Delivery Time: | - |

| Supplying Ability: | - |

| Payment Type: | - |

| Product Group : | Plastic Recycling Machine |