FOB Price

Get Latest Price1000 ~ 50000 USD / Set

|1 Set Minimum Order

Country:

China

Model No:

SFM

FOB Price:

1000 ~ 50000 USD / Set Get Latest Price

Place of Origin:

-

Price for Minimum Order:

1000 per Set

Minimum Order Quantity:

1 Set

Packaging Detail:

CASE

Delivery Time:

30 DAYS

Supplying Ability:

1000 Set per Year

Payment Type:

L/C, T/T

Product Group :

-

Contact Person MAX

Shanhu Street, Shaoxing, Zhejiang

Coarse crusher*-Lifter*-Feed bin*-Fine

grinder*-Cyclone collector*-Vibrating sieve*-Screw

feeder*-Magnetic separator*-Electrostatic separator*-Dust

collector

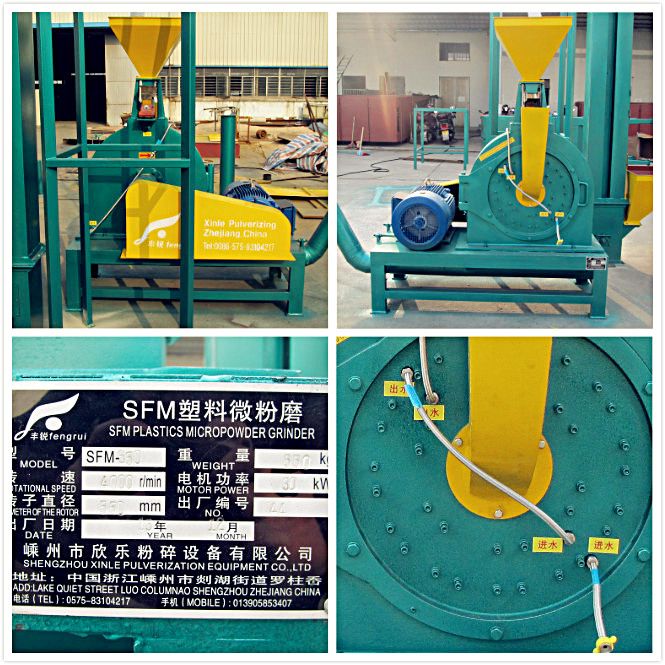

SFM Plastic Grinder

Summary

After many years research and develop, our factory successfully produce the SFM plastic powder grinding. It can grind at normal temperature of plastic materials (polyethylene, polyvinyl chloride, polypropylene, nylon etc). Compared with the low temperature cooling grinding equipment, SFM has the advantages of energy consumption, uniform product size, convenient operation etc. It is the ideal equipment for

Style and name

S F M-**0

↓↓↓→→→→→→→→→Style number

↓↓→→→→→→→→→→→Fine grinder

↓→→→→→→→→→→→→Thermoplastic

Application and characteristic

1. Application: Many kinds of plastic

2. Characteristic

The design of grinding disc is novel and unique, it has the function of shear, impact, and grinding, uniform particle size, narrow distribution.

When grinding, the temperature inside the machine will get very high. So we have a cooling design, like a water jacket, after connecting with the water chiller or cold air chiller, it can maintain the temperature at a normal range when operating the machine.

This grinder adopts novel and strong narrow V drives. It has the advantage of small transmission power, smooth operation, and high efficiency. The bearing is all imported from Japanese, and we inspect every part before assembly.

It is convenient to repair, operation and cleaning.

It is no need to use screen, the fineness is adjustable.

Structure and working principle

This machine is composed of frame, body, feed hopper, grinding device, discharge pipe, transmission device and motor. The internal structure is shown below. The whole set equipment is including host machine, blower, cyclone, Kwan fan motor, deduster, electric cabinet and vibrating screen. When operation, First the material is went into the grinding part which composed by moving grinding disc and fixed grinding disc. Due to the high speed rotating of moving grinding disc and also under the function of blower, the material is being cut, impact, friction, the particle size become small, and moving outward, finally go through the pipe and collected by the cyclone.

Main technical date

|

Date Style |

Rotor diameter (mm) |

Power (KW) |

Fineness (mesh) |

Capacity (kg/h) |

Speed (rpm) |

Weight (kg) |

|

SFM**0 |

**0 |

****5 |

*****0 |

*****0 |

***0 |

**0/***0 |

|

SFM**0 |

**0 |

****7 |

*****0 |

*****0 |

***0 |

**0/***0 |

|

SFM**0 |

**0 |

*8.***2 |

*****0 |

*****0 |

***0 |

**0/***0 |

|

SFM**0 |

**0 |

*5 |

*****0 |

****0 |

***0 |

**0/**0 |

Install & Operation

Each equipment should be connected securely. The joints of pipes should tight to prevent air come out.

Before starting the machine, it should be strictly checked if the connection of pipe is loose, the rotation is flexible, the direction of rotation is meeting the requirement, if not, it should be excluded before starting.

The material should not contain gold, stone and other hard objects, or it will damage the machine.

Before starting the machine should be filled with cold water, especially for soft materials.

Check the belt tension regularly, to prevent the belt slipping.

Add the lubricating oil regularly, normally once a week. If operating continuously, add every *4 hours.

Wearing parts

|

name

Style |

Bearing style |

Bearing QTY(pc) |

Oil seal |

Oil seal QTY(pc) |

Triangle belt

|

Triangle belt QTY(pc) |

|

SFM***0 |

***8 |

2 |

*0**0**0 *0**5**0 |

1 1 |

A***7 |

3 |

|

SFM***0 |

***0 |

2 |

*0**0**0 *5**5**0 |

1 1 |

A***1 |

5 |

|

SFM***0 |

***4 |

4 |

*5***0**2 *0**5**2 |

1 1 |

B***2 |

6 |

|

SFM***0 |

***4 |

4 |

*5***0**2 *0**5**2 |

1 1 |

B***0 |

6 |

| Country: | China |

| Model No: | SFM |

| FOB Price: | 1000 ~ 50000 / Set Get Latest Price |

| Place of Origin: | - |

| Price for Minimum Order: | 1000 per Set |

| Minimum Order Quantity: | 1 Set |

| Packaging Detail: | CASE |

| Delivery Time: | 30 DAYS |

| Supplying Ability: | 1000 Set per Year |

| Payment Type: | L/C, T/T |

| Product Group : | - |